Preheating ring for epitaxial growth equipment, and epitaxial growth equipment

An epitaxial growth, preheating ring technology, applied in gaseous chemical plating, coating, electrical components and other directions, can solve the problems of reduced film uniformity, poor deposition efficiency, etc., to improve film uniformity, improve deposition efficiency, The effect of preventing turbulence and additional flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

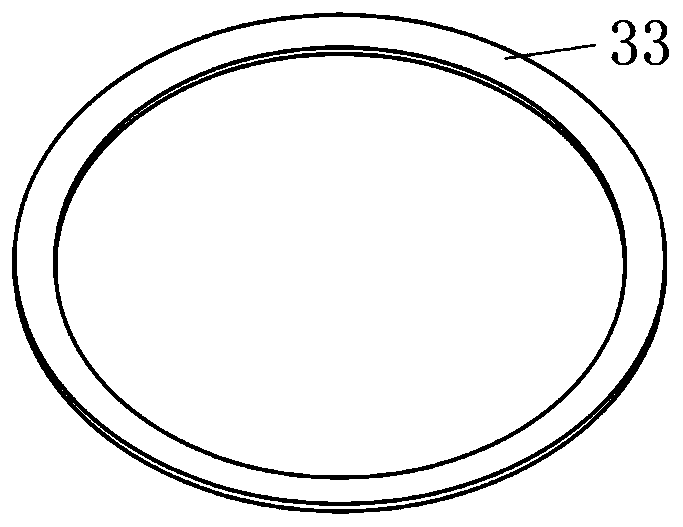

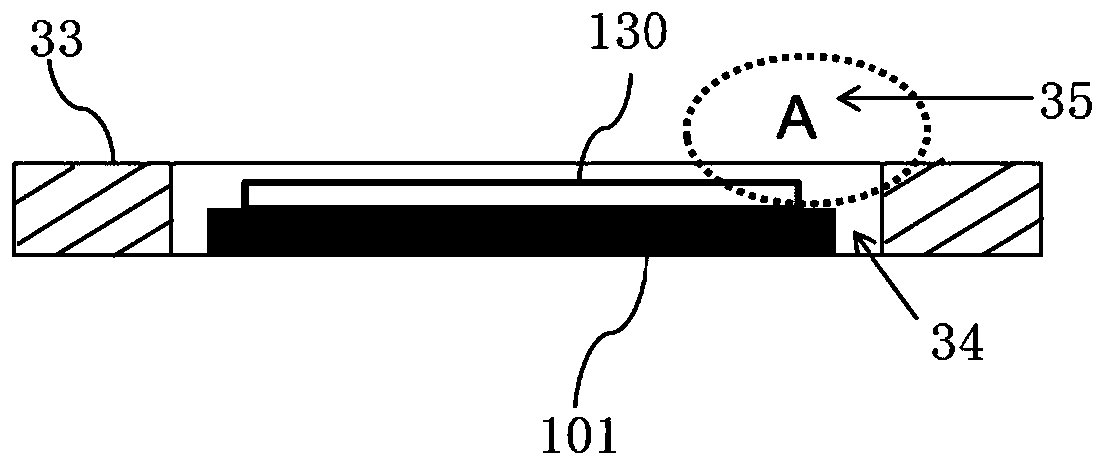

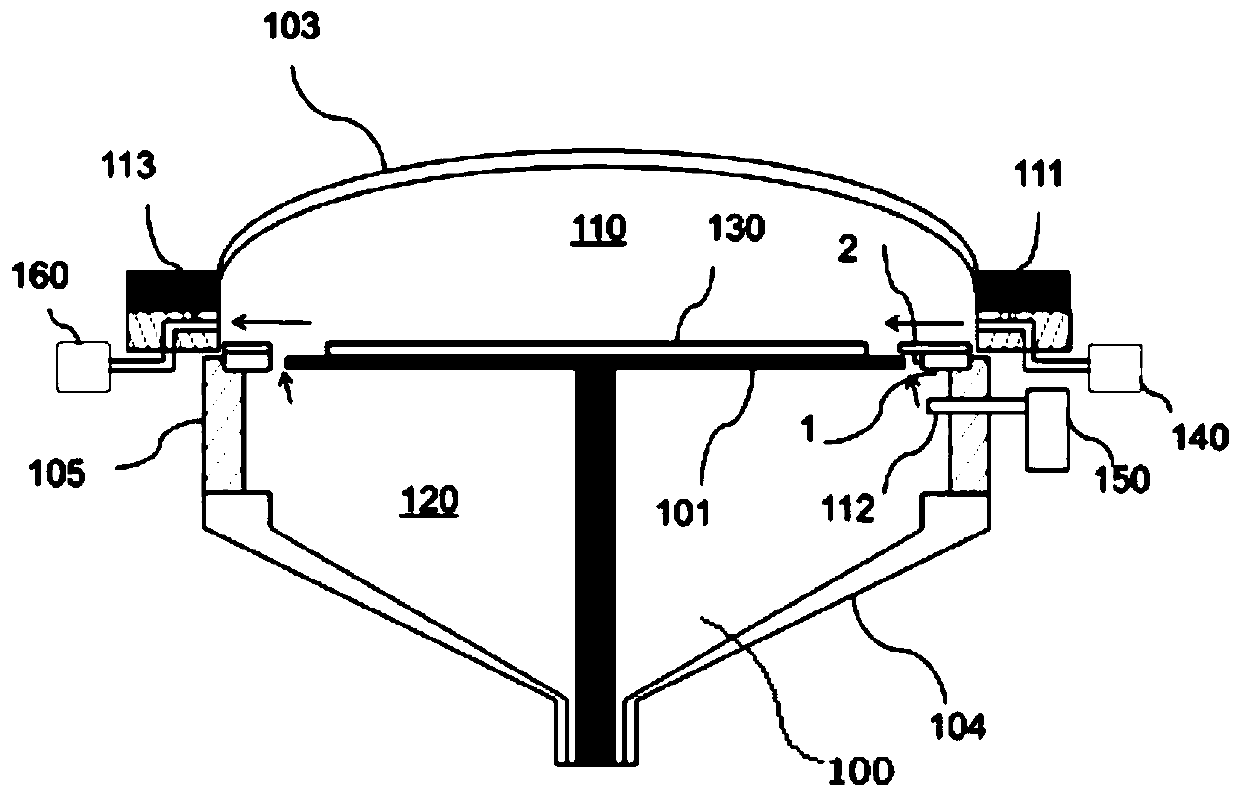

[0057] image 3 shows a schematic structural view of an epitaxial growth device according to an embodiment of the present invention, Figure 4 shows a schematic structural diagram of a preheating ring according to an embodiment of the present invention, Figure 5 shows a schematic structural view of an upper ring part according to an embodiment of the present invention, Figure 6 A schematic structural diagram of a lower ring part according to an embodiment of the present invention is shown.

[0058] Such as image 3 As shown, an epitaxial growth device of this embodiment includes: a reaction chamber, a base located in the reaction chamber, and a preheating ring, the preheating ring surrounds the outer periphery of the base, and there is a gap between the base and the base , One side of the reaction chamber is provided with a gas discharge area, and the other side is provided with a processing gas intake area, and the exhaust channel is close to the gas discharge area, and ...

Embodiment 2

[0069] Figure 7 shows a schematic structural diagram of another preheating ring according to an embodiment of the present invention, Figure 8 show Figure 7 Partial enlarged view at B, Figure 9 It shows a schematic structural diagram of another upper ring part according to an embodiment of the present invention, Figure 10A schematic structural diagram of another lower ring part according to an embodiment of the present invention is shown.

[0070] Such as Figure 7-Figure 10 As shown, another preheating ring of the embodiment includes an upper ring part 2 and a lower ring part 1. The upper ring part 2 and the lower ring part 1 are stacked coaxially from top to bottom. The outer diameters of the ring parts 1 are equal, the inner diameter of the upper ring part 2 is smaller than the inner diameter of the lower ring part 1, and an exhaust passage is provided on one side of the upper ring part 2. The exhaust passage includes a plurality of through holes 25, which are dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com