Blue-light perovskite light-emitting diode based on modified hole transport layer and production method thereof

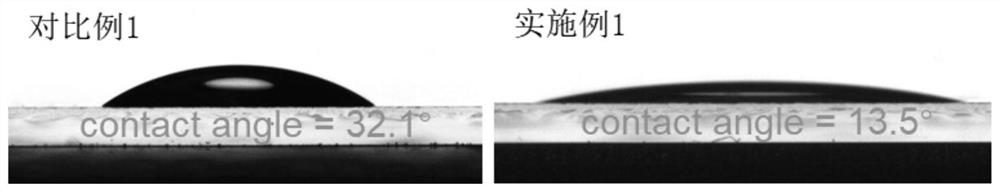

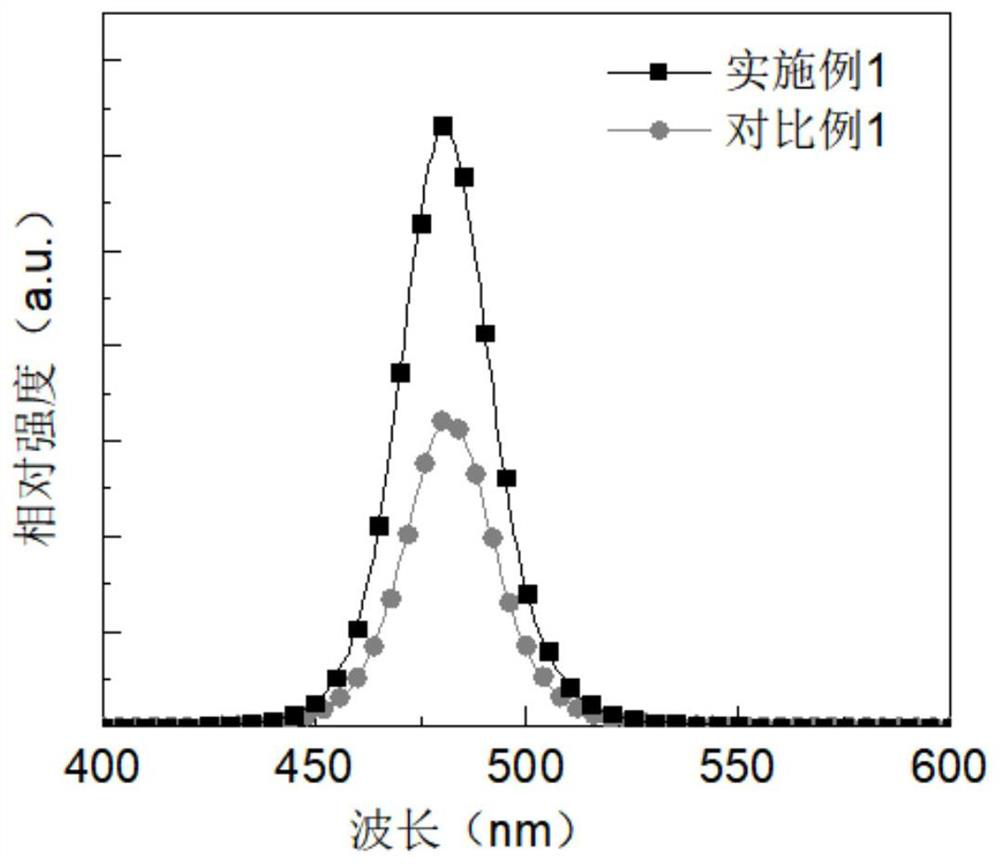

A hole transport layer and light emitting diode technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of perovskite emission wavelength shift, complex processing technology, and complicated actual operation, and achieve passivation. Perovskite defects, simple operation, and the effect of improving the uniformity of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

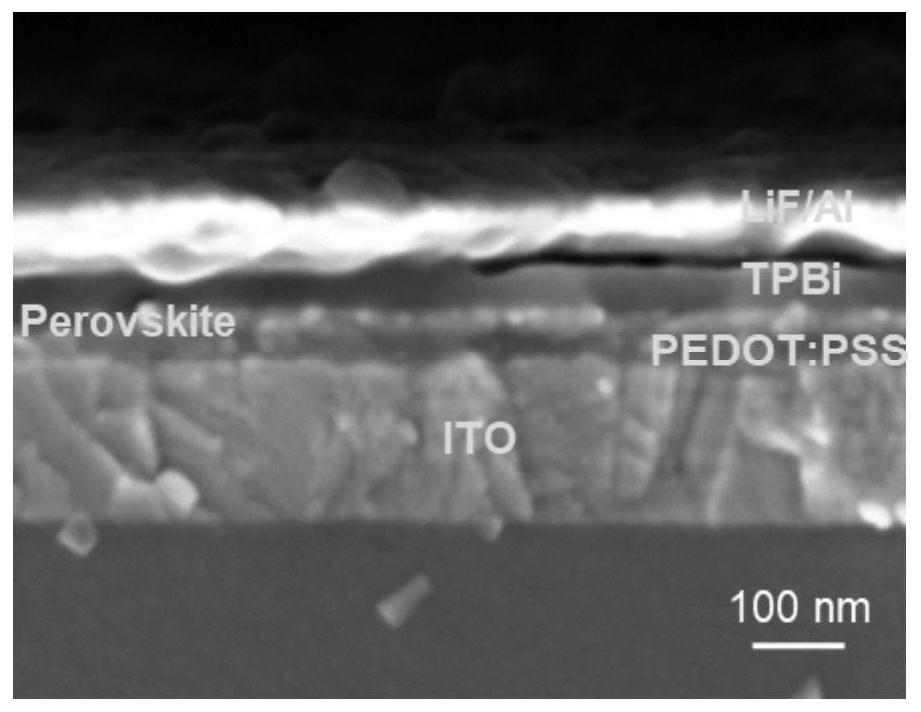

[0031] As a specific embodiment, taking propanolamine as an example, the preparation method of the blue light perovskite light-emitting diode based on the modified hole transport layer of the present invention is the following detailed steps:

[0032] S1. Clean the anode substrate ultrasonically with diluted Decon aqueous solution, then rinse the ITO anode substrate with deionized water, then place it in ethanol and isopropanol for ultrasonic cleaning for 5-10 minutes, and finally dry it in an oven;

[0033] S2. mixing the propanolamine additive into the PEDOT:PSS stock solution to prepare a PEDOT:PSS solution with a doping concentration of 1-3 μl / ml;

[0034] S3. Spin-coat the PEDOT:PSS solution at 4000 rpm / min for 40 s, and then anneal at 140°C for 15 minutes at a high temperature to form a hole transport layer;

[0035] S4. In the glove box (nitrogen protection), CsBr, PbBr 2 , PbCl 2 , KBr, p-f-PEABr and formamidine hydrobromide (FABr) were dissolved in DMSO according to...

Embodiment 1

[0038] Example 1 A blue-light perovskite light-emitting diode based on a modified hole transport layer, the preparation method of which is as follows:

[0039](1) Ultrasonic clean the ITO anode substrate with a 20-fold diluted Decon aqueous solution for 5 minutes, then rinse the ITO anode substrate with deionized water, then place it in ethanol and isopropanol for 5 minutes, and finally dry it in an oven ;

[0040] (2) Add 2 μL of propanolamine to 1 mL of PEDOT:PSS stock solution to prepare a PEDOT:PSS solution with a doping concentration of 2 μl / ml;

[0041] (3) The above PEDOT:PSS solution was spin-coated on the surface of the ITO anode at 4000 rpm / min for 40 s, and then annealed at 140 °C for 15 minutes to form a hole transport layer;

[0042] (4) Mix 0.282 mmol of CsBr and 0.067 mmol of PbBr in a glove box (nitrogen protection) 2 , 0.134mmol of PbCl 2 , 0.05 mmol of KBr, 0.08 mmol of p-f-PEABr and 0.03 mmol of formamidine hydrobromide (FABr) were dissolved in 1.8 ml of ...

Embodiment 2

[0058] The difference between this embodiment and Embodiment 1 lies in that in step (1), the effective area of the ITO anode substrate used is different, and the size of the light emitting area of the finally manufactured device is different. In this embodiment, the light-emitting area of the blue perovskite light-emitting diode based on the modified hole transport layer is 100 mm 2 . The rest of the parameters are the same. as follows:

[0059] (1) Ultrasonic clean the ITO anode substrate with a 20-fold diluted Decon aqueous solution for 5 minutes, then rinse the ITO anode substrate with deionized water, then place it in ethanol and isopropanol for 5 minutes, and finally dry it in an oven ;

[0060] (2) Add 2 μL of propanolamine to 1 mL of PEDOT:PSS stock solution to prepare a PEDOT:PSS solution with a doping concentration of 2 μl / ml;

[0061] (3) The above PEDOT:PSS solution was spin-coated on the surface of the ITO anode at 4000 rpm / min for 40 s, and then annealed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com