Formation process of lithium ion battery

A lithium-ion battery and process technology, applied in secondary batteries, electrochemical generators, secondary battery charging/discharging, etc., can solve the problem that SEI film density and stability are greatly affected, and electrolyte wettability SEI cannot be guaranteed. Membrane stability and compactness and other issues, to achieve the effect of increasing the module assembly rate, shortening the infiltration time, and improving the infiltration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 Preparation of lithium ion battery (1)

[0049] A. Take 5 pre-sealed lithium battery cells and let them stand at 45°C:

[0050] 1) Let stand for 2 hours;

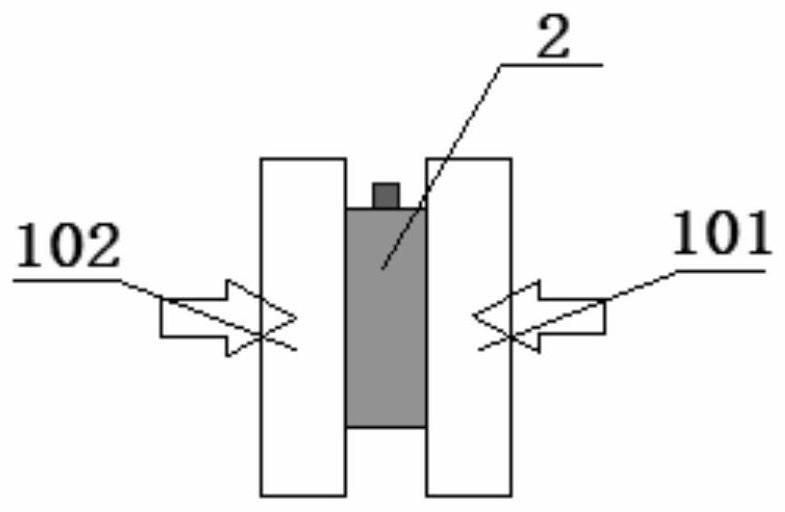

[0051] 2) Use a clamp to clamp the cell, the clamping method is as follows figure 1 As shown, the splints 101 and 102 exert pressure on the two surfaces of the battery cell 2, the arrow points to the direction of the force, the clamp pressure is 0.2MPa, and the time is 5 minutes;

[0052] 3) Loosen the clamp, and let the cell stand for 60 minutes at normal pressure;

[0053] 4) Repeat steps 2) and 3) 30 times;

[0054] B. Clamp the cell after standing still with a fixture at 45°C for charging and discharging. The fixture pressure is 0.2MPa:

[0055] 1) 0.02C current charging to 3.2V;

[0056] 2) 0.1C constant current charging to 3.6V;

[0057] 3) 0.2C constant current charging to 4.2V;

[0058] 4) 0.5C discharge to 3.6V.

[0059] C. Let the charged and discharged batteries stand in an environment of...

Embodiment 2

[0064] Embodiment 2 prepares lithium-ion battery (two)

[0065] A. Take 5 pre-sealed lithium battery cells and let them stand at 45°C:

[0066] 1) Let stand for 2 hours;

[0067] 2) Use a clamp to clamp the cell, the clamping method is as follows figure 1 As shown, apply pressure to the two surfaces of the battery, the clamp pressure is 0.3MPa, and the time is 5 minutes;

[0068] 3) Loosen the clamp, and let the cell stand for 60 minutes at normal pressure;

[0069] 4) Repeat steps 2) and 3) 30 times;

[0070] B. Clamp the cell after standing still with a fixture at 45°C for charging and discharging. The fixture pressure is 0.3MPa:

[0071] 1) 0.02C current charging to 3.2V;

[0072] 2) 0.1C constant current charging to 3.6V;

[0073] 3) 0.2C constant current charging to 4.2V;

[0074] 4) 0.5C discharge to 3.6V.

[0075] C. Let the charged and discharged batteries stand in an environment of 45°C:

[0076] 1) The cell is clamped with a clamp, the clamp pressure is 0.3MPa...

Embodiment 3

[0080] Example 3 Preparation of Lithium-ion Battery (3)

[0081] A. Take 5 pre-sealed lithium battery cells and let them stand at 40°C:

[0082] 1) Let stand for 2 hours;

[0083] 2) Use a clamp to clamp the cell, the clamping method is as follows figure 1 As shown, apply pressure to the two surfaces of the battery, the clamp pressure is 0.4MPa, and the time is 5 minutes;

[0084] 3) Loosen the clamp, and let the cell stand for 60 minutes at normal pressure;

[0085] 4) Repeat steps 2) and 3) 30 times;

[0086] B. Clamp the cell after standing still with a fixture at 40°C for charging and discharging. The fixture pressure is 0.4MPa:

[0087] 1) 0.02C current charging to 3.2V;

[0088] 2) 0.1C constant current charging to 3.6V;

[0089] 3) 0.2C constant current charging to 4.2V;

[0090] 4) 0.5C discharge to 3.6V.

[0091] C. Let the charged and discharged cells stand in an environment of 40°C:

[0092] 1) The cell is clamped with a clamp, the clamp pressure is 0.4MPa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com