Efficient scraper film evaporation device

An evaporation device and scraper technology, applied in evaporation, evaporator accessories, chemical instruments and methods, etc., can solve problems such as unsatisfactory evaporation effect, incomplete gas-liquid separation, uneven film distribution on the inner wall of the cylinder, etc., to eliminate Secondary steam short circuit, strong anti-clogging ability, and the effect of preventing crystallization and scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

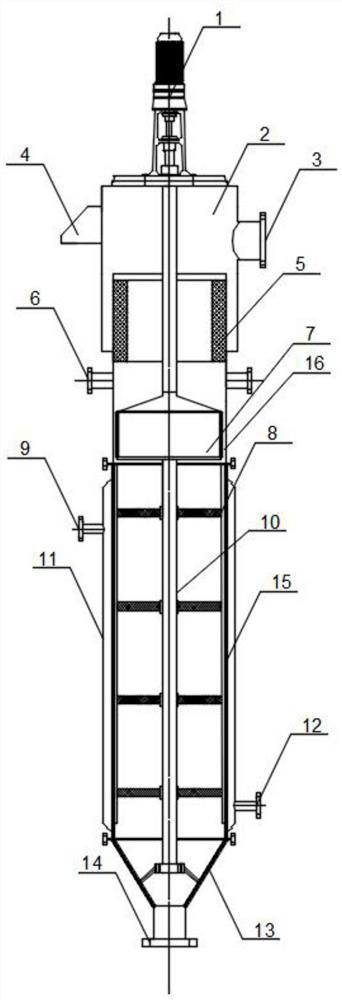

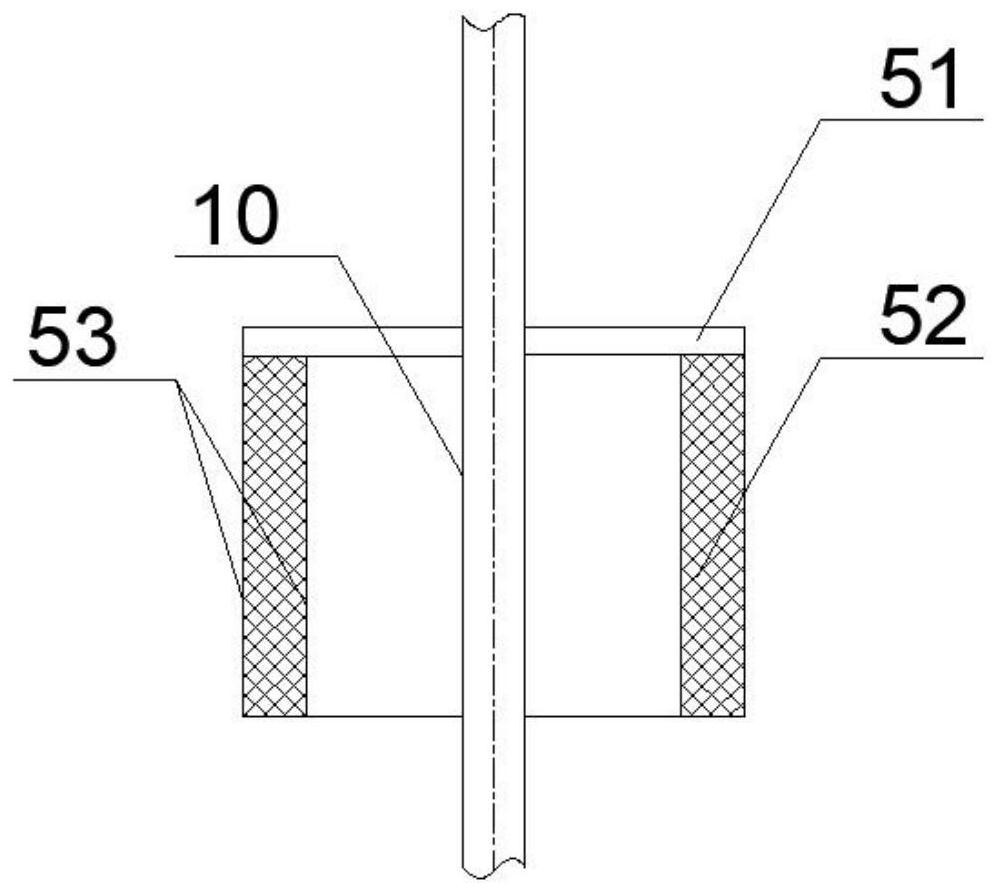

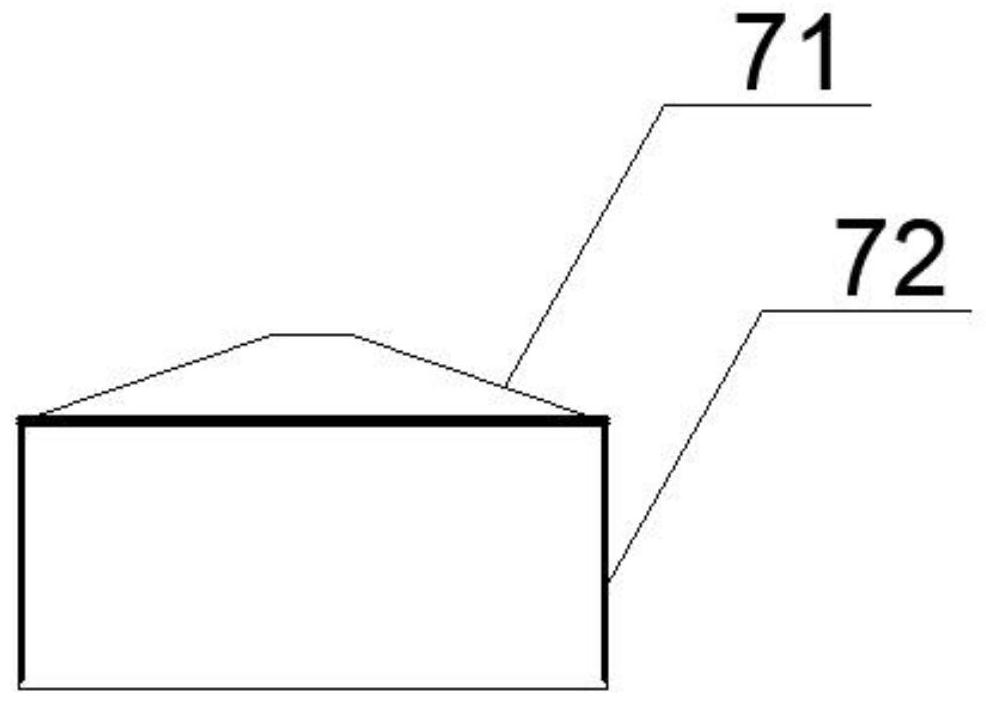

[0034] A high-efficiency scraper thin-film evaporation device, the innovation of which is that it includes a geared motor 1, a separation chamber 2, a gas-liquid separator 5, and an evaporator cylinder 15. The geared motor is arranged at the upper end of the separation chamber, and the The lower end of the separation chamber is connected to the gas-liquid separator, and the bottom end of the gas-liquid separator is connected to the cylinder of the evaporator, and a rotating shaft 10 is coaxially arranged in the cylinder of the evaporator, and the rotating shaft runs through the The gas-liquid separator and the separation chamber are connected to the end of the motor shaft of the geared motor. The rotating shaft in the cylinder of the evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com