Chemical vapor deposition equipment

A technology of chemical vapor deposition and equipment, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of uneven coating thickness, etc., to improve the uniformity of film formation, improve product yield, make up for The effect of local defect bad problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

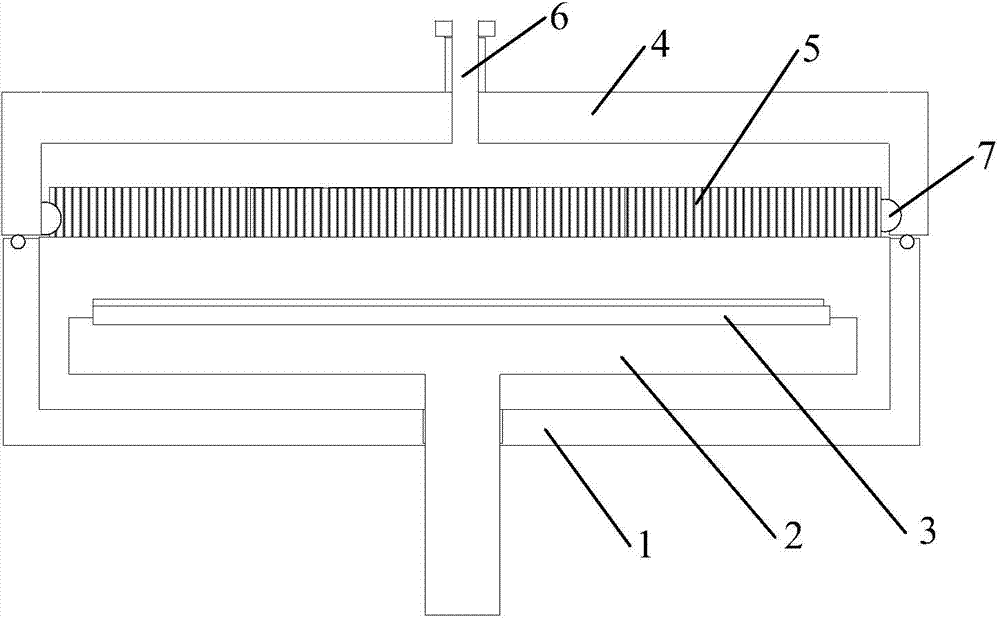

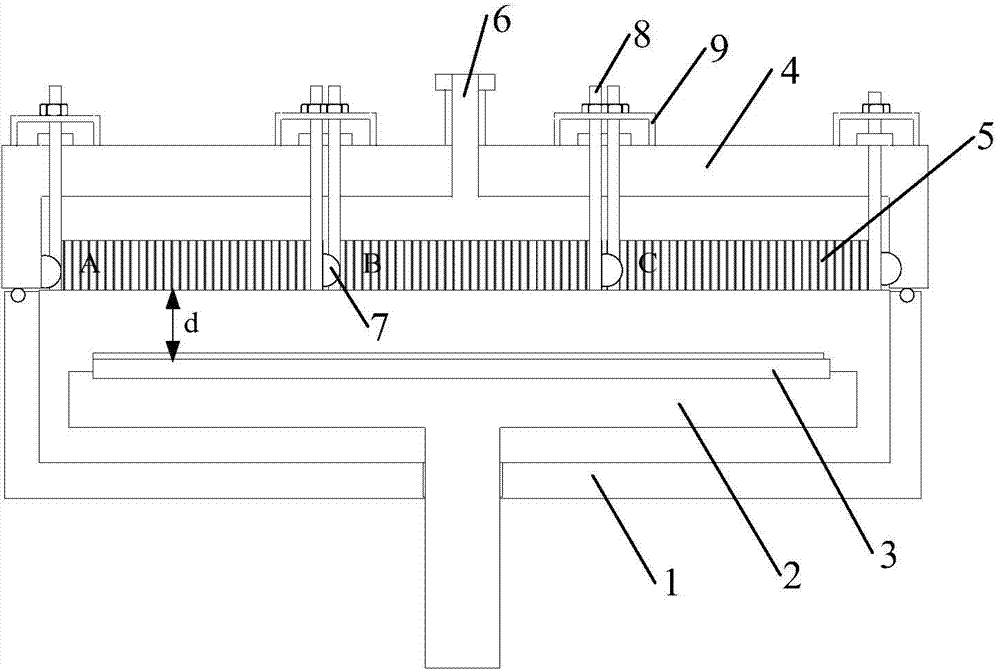

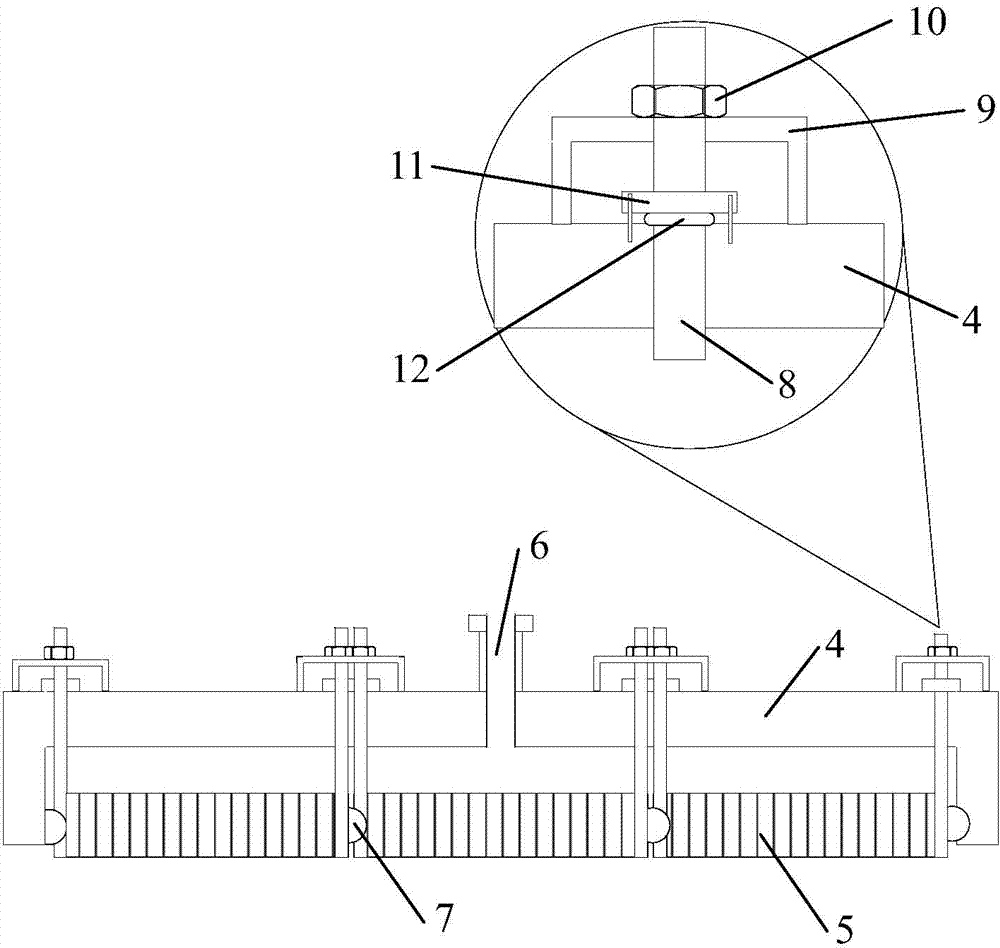

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0026] In order to solve the phenomenon that the upper and lower electrode plates are deformed and the aperture of the gas diffuser is locally enlarged due to the aging of spare parts in the chemical vapor deposition equipment in the prior art, which causes the phenomenon that the locally deposited film layer on the substrate is relatively thick and the locally deposited film layer is relatively thin, the present invention The gas diffuser is set as a split structure, and each split diffuser is equipped with a lifting adjustment mechanism to separately control the distance between the local upper and lower electrode plates. When the local deposited film is thick, the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com