Hole injection layer ink, organic light-emitting device and manufacture method of hole injection layer ink

A technology of hole injection layer and manufacturing method, which is applied in the fields of electrical solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of affecting the uniformity of film formation of the hole transport layer and the inability to effectively control the ink climbing of the hole transport layer. climbing height etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

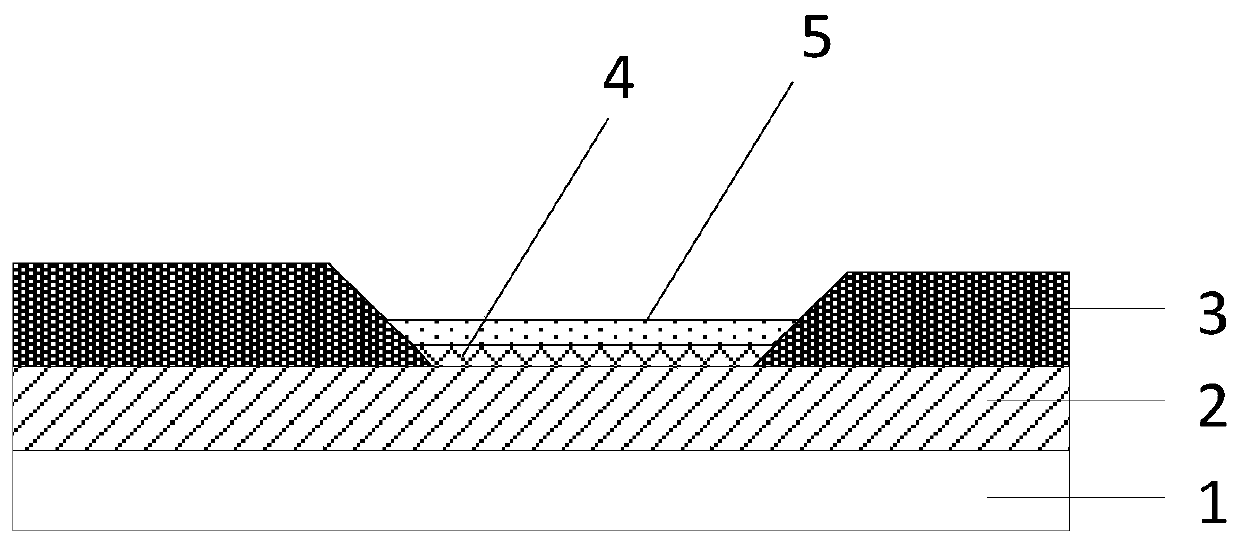

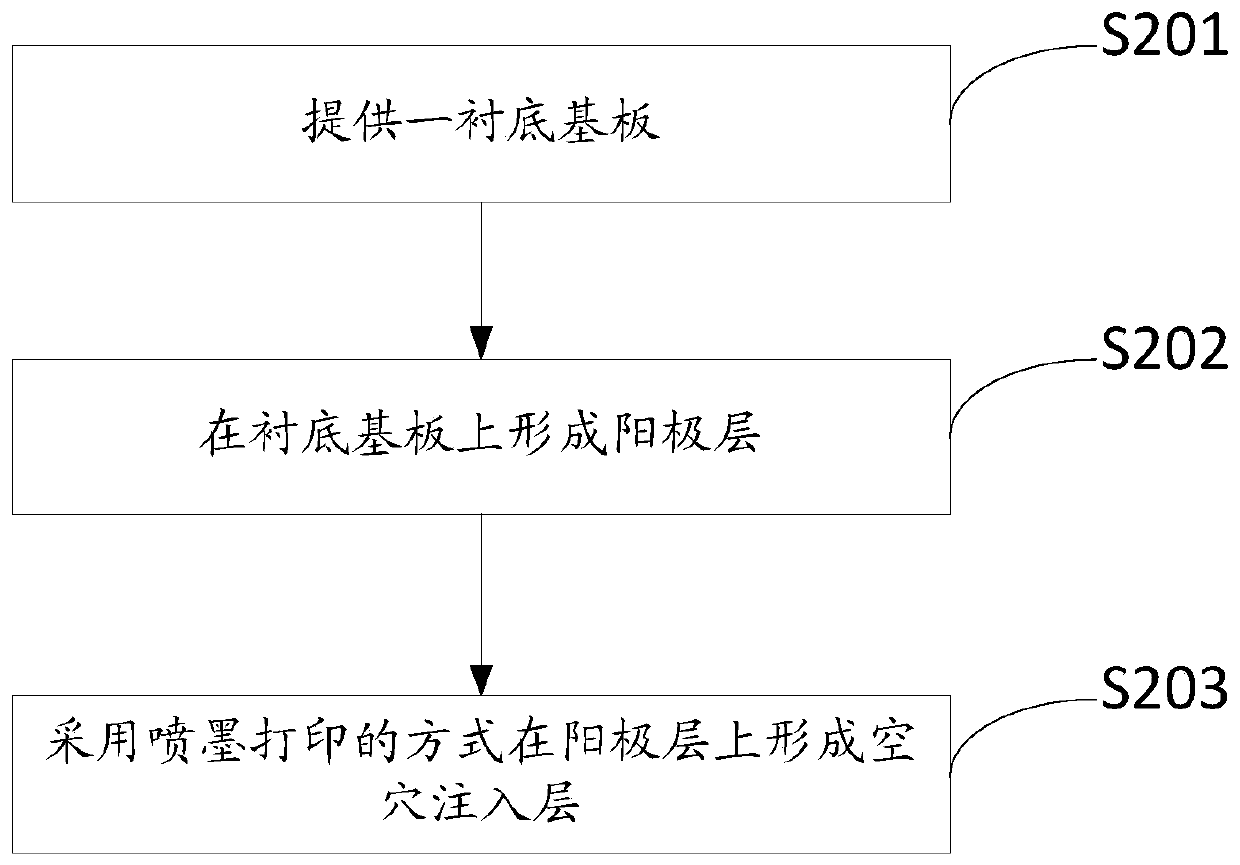

[0030] Inkjet printing has the advantages of low equipment cost, no size limit, and full-color printing. In the related art, when the hole injection layer and the hole transport layer are fabricated by inkjet printing, the pixel definition layer is used to limit the pixel size and ink flow, and at the same time match the performance of the ink to meet the requirements of uniformity of film formation. During the film forming process, after the hole injection layer is formed in the pixel defining layer, the hole injection layer ink will climb a certain amount on the pixel defining layer, and the hole cannot be effectively controlled when printing the hole transport layer. The climbing height of the ink in the transport layer affects the uniformity of film formation of the hole transport layer.

[0031] In view of the above-mentioned problems existing in the hole injection layer ink in the related art, the embodiment of the present invention provides a hole injection layer ink, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com