Method of preparing conductive carbon fiber/platinum nanometer material and application of conductive carbon fiber/platinum nanometer material

A conductive carbon fiber, platinum nanotechnology, applied in the field of nanomaterials, can solve the problems of dye-sensitized solar cells industrialization application obstacles, high preparation cost, low overpotential, etc., and achieves favorable development and utilization, low cost and simplified production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

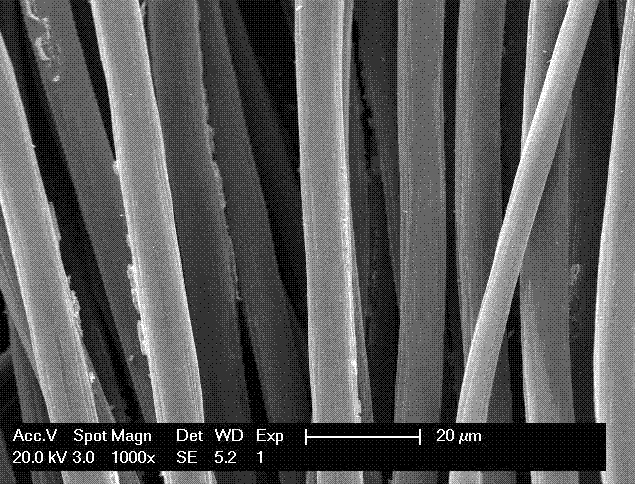

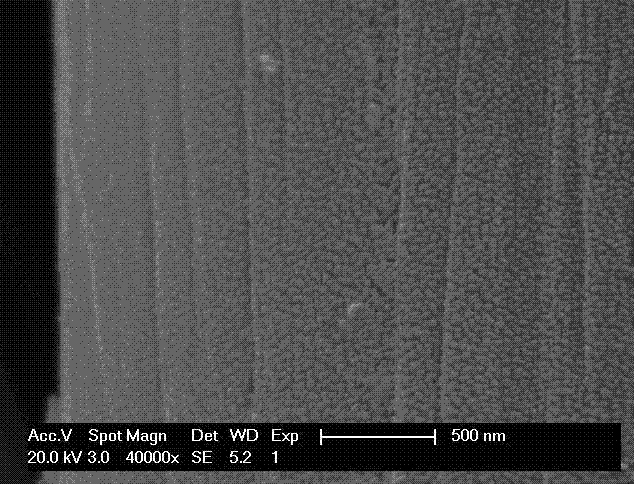

[0027] Conductive carbon fibers (diameter 0.4mm, conductivity 10Ω / cm) were ultrasonically cleaned with deionized water, absolute ethanol and acetone for 5 minutes, dried, immersed in 10mM ethanol solution of chloroplatinic acid overnight, and then in 385 o C and sintered for 20 minutes to obtain a platinum-loaded conductive carbon fiber material. Such as figure 1 , figure 2 As shown, the diameter of platinum nanoparticles is 21~43nm, which are uniformly loaded on the conductive carbon fibers.

[0028] Application of conductive carbon fiber / platinum nanomaterials as flexible counter electrodes for dye-sensitized solar energy

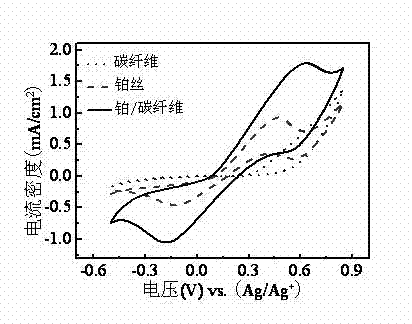

[0029] Using an electrochemical workstation, cyclic voltammetry was used to analyze the platinum-loaded conductive carbon fiber counter electrode pair I 3 - / I - The catalytic activity of the pair was studied. The cyclic voltammetry scan uses a three-electrode system, and the reference electrode is Ag / Ag + , the counter electrode is Pt, and the ...

Embodiment 2

[0035] Conductive carbon fibers (diameter 0.3 mm, conductivity 9 Ω / cm) were ultrasonically cleaned with deionized water, absolute ethanol and acetone for 5 minutes in sequence, dried, and immersed in 5 mM chloroplatinic acid in isopropanol solution overnight. then at 380 o C and sintered for 25 minutes to obtain a platinum-loaded conductive carbon fiber material. The diameter of platinum nanoparticles is 16~30nm.

[0036] Application of conductive carbon fiber / platinum nanomaterials as flexible counter electrodes for dye-sensitized solar energy

[0037] Using an electrochemical workstation, cyclic voltammetry was used to analyze the platinum-loaded conductive carbon fiber counter electrode pair I 3 - / I - The catalytic activity of the pair was studied. The cyclic voltammetry scan uses a three-electrode system, and the reference electrode is Ag / Ag + , the counter electrode is Pt, and the electrolyte contains 0.1M LiClO 4 , 10M LiI and 1M I 2 Acetonitrile solution, the...

Embodiment 3

[0040] Conductive carbon fibers (diameter 0.3mm, conductivity 9Ω / cm) were ultrasonically cleaned with deionized water, absolute ethanol and acetone for 5 minutes, dried, immersed in 30mM ethanol solution of chloroplatinic acid overnight, and then in 380 o C and sintered for 25 minutes to obtain a platinum-loaded conductive carbon fiber electrode. The diameter of platinum nanoparticles is 34~50nm.

[0041] Application of conductive carbon fiber / platinum nanomaterials as flexible counter electrodes for dye-sensitized solar energy

[0042] Utilize the electrochemical workstation, adopt the cyclic voltammetry to measure the conductive carbon fiber counter electrode pair I loaded with platinum in the vegetation 3 - / I - The catalytic activity of the pair was studied. The cyclic voltammetry scan uses a three-electrode system, and the reference electrode is Ag / Ag + , the counter electrode is Pt, and the electrolyte contains 0.1M LiClO 4 , 10M LiI and 1M I 2 Acetonitrile sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com