Rapid clamping structure and mechanical clamping device

A clamping device and clamping technology, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve the problems of low machine utilization rate, long downtime, long correction time, etc., and improve machine utilization The effect of high efficiency, reduced downtime, and precise positioning of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

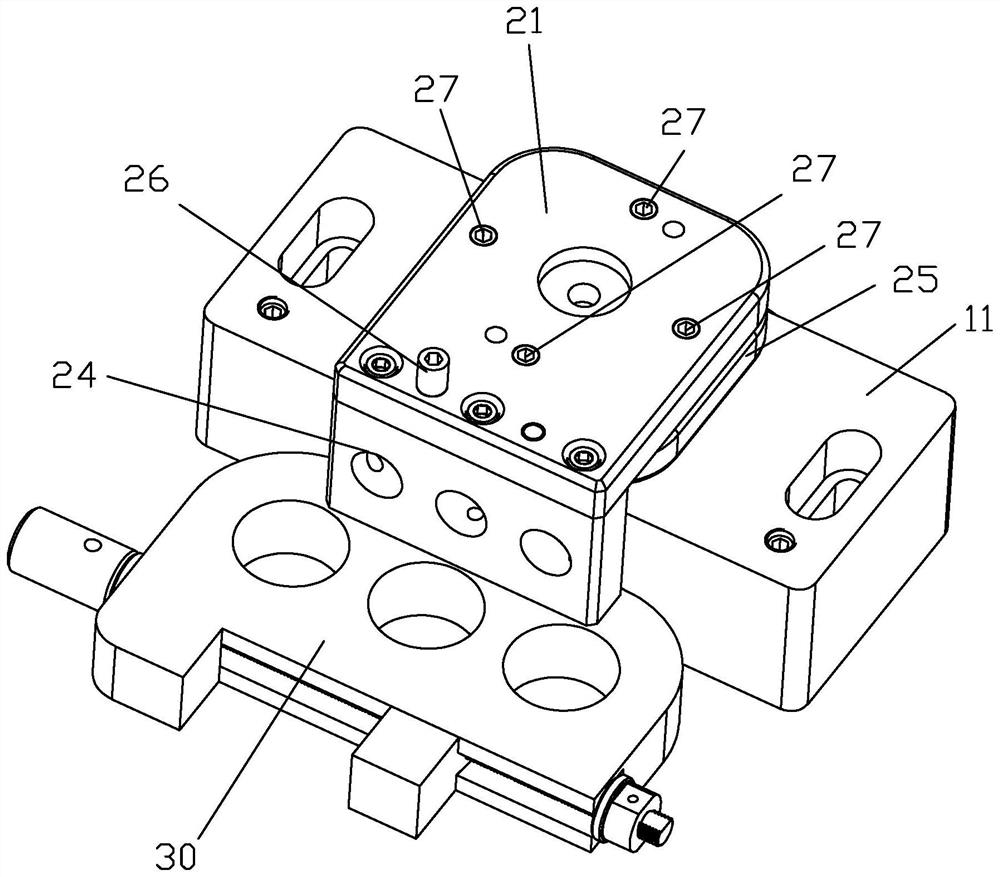

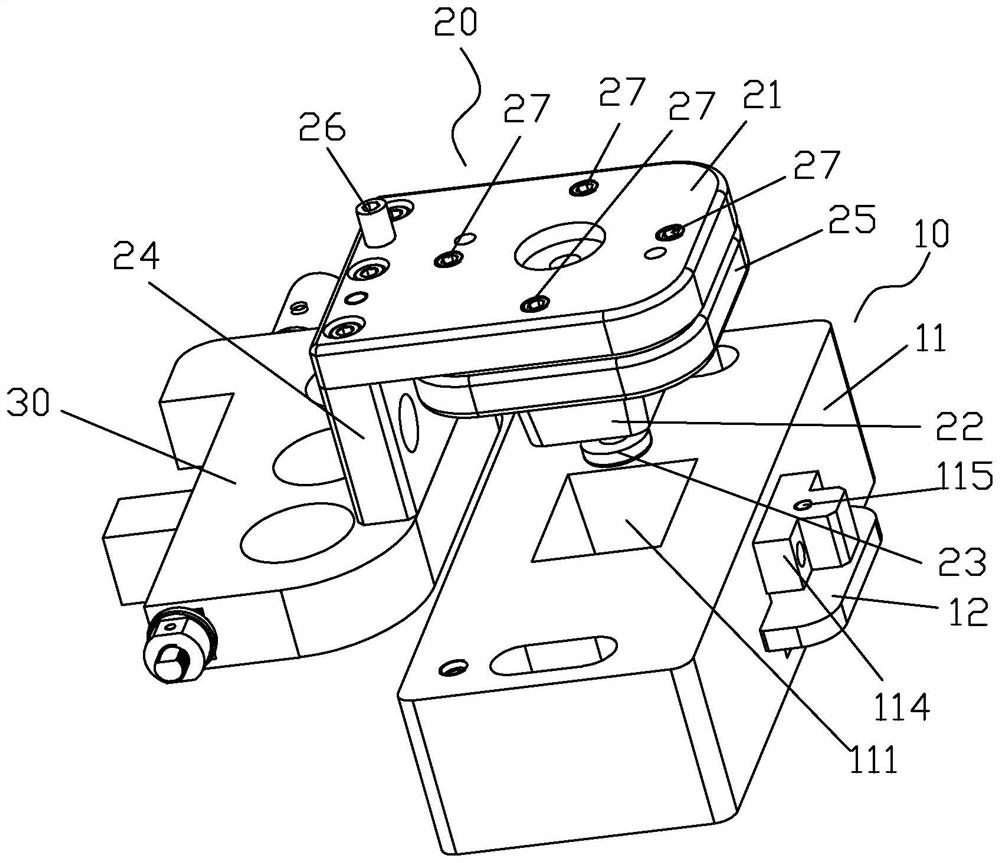

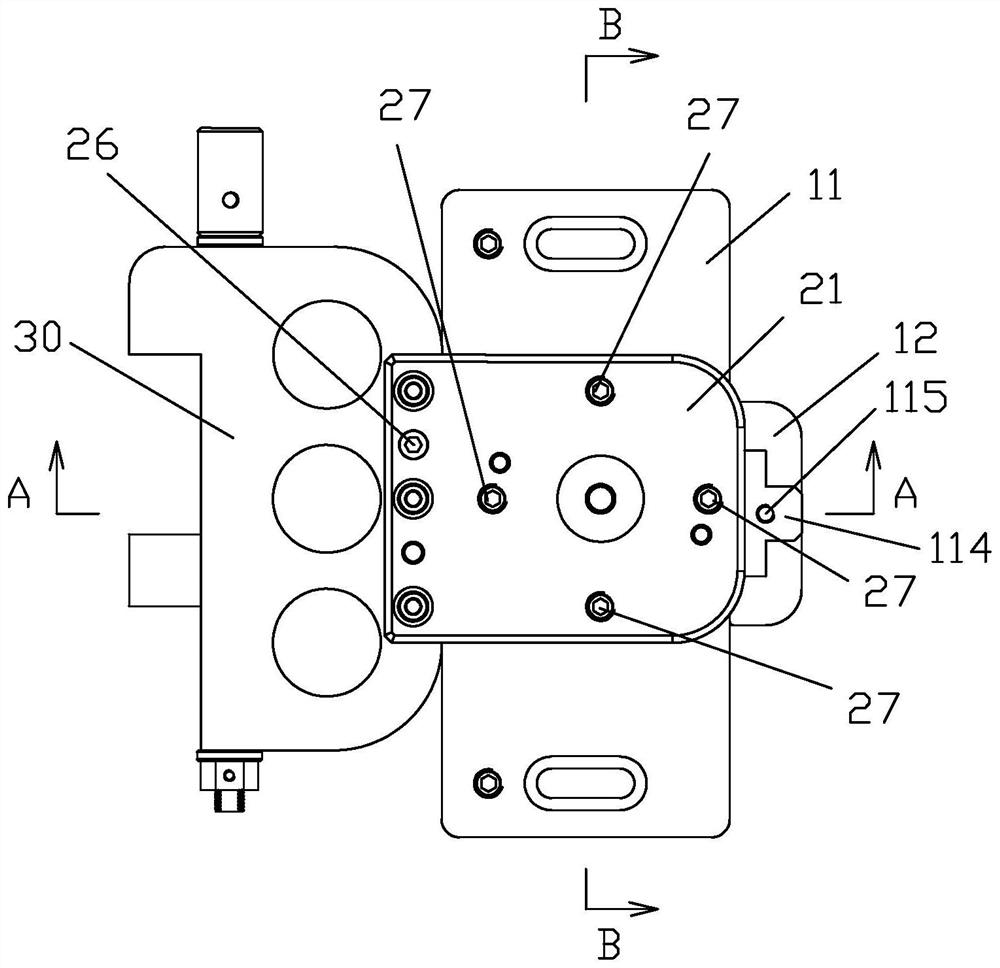

[0031] This embodiment provides a quick clamping structure, such as Figure 1 to Figure 10 As shown, it includes a fixing device 10 and an exchange device 20. The fixing device 10 includes a fixing base 11 and a clamping plate 12. The fixing base 11 is provided with a frustum-shaped positioning channel 111 that is wide at the top and narrow at the bottom. The clamping plate 12 is movably arranged at the bottom of the positioning slot 111 , and has a large opening 121 and a small opening 122 connected thereto. The big mouth 121 is used for giving way, and the small mouth 122 is used for clamping.

[0032] More specifically, the fixed base 11 has a slot 113 arranged horizontally, and the slot 113 is located at the bottom of the positioning channel 111 ;

[0033] The exchange device 20 includes a fixed plate 21 and a positioning block 22 and a connecting block 24 respectively fixed on the fixed plate 21, and the connecting block 24 is used to connect a working fixture 30 (such a...

Embodiment 2

[0043] This embodiment provides a mechanical clamping device, including a processing machine tool, a fixing device, an exchange device for assembling on the fixing device, and a work fixture assembled on the exchange device; the number of the fixing devices is at least two , which is used to switch between the external preset position and the internal position of the processing machine tool; in this way, it is possible to assemble the work fixture at the external preset position first, and then transfer it to the machine tool (that is, the internal position) for processing Operation, can avoid long downtime to install and replace the operation fixture.

[0044] Specifically, the installation structure of the fixing device and the interchange device is the same as the quick clamping structure in Embodiment 1, specifically: refer to Figure 1 to Figure 10 As shown, the fixing device 10 includes a fixing base 11 and a clamping plate 12. The fixing base 11 is provided with a trunc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com