A method for assembling an electronic product

A technology for electronic products and assembly methods, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low assembly efficiency, difficult assembly of studs 11, and failure to meet production requirements, and achieves improved efficiency and rapidity. The effect of positioning assembly and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

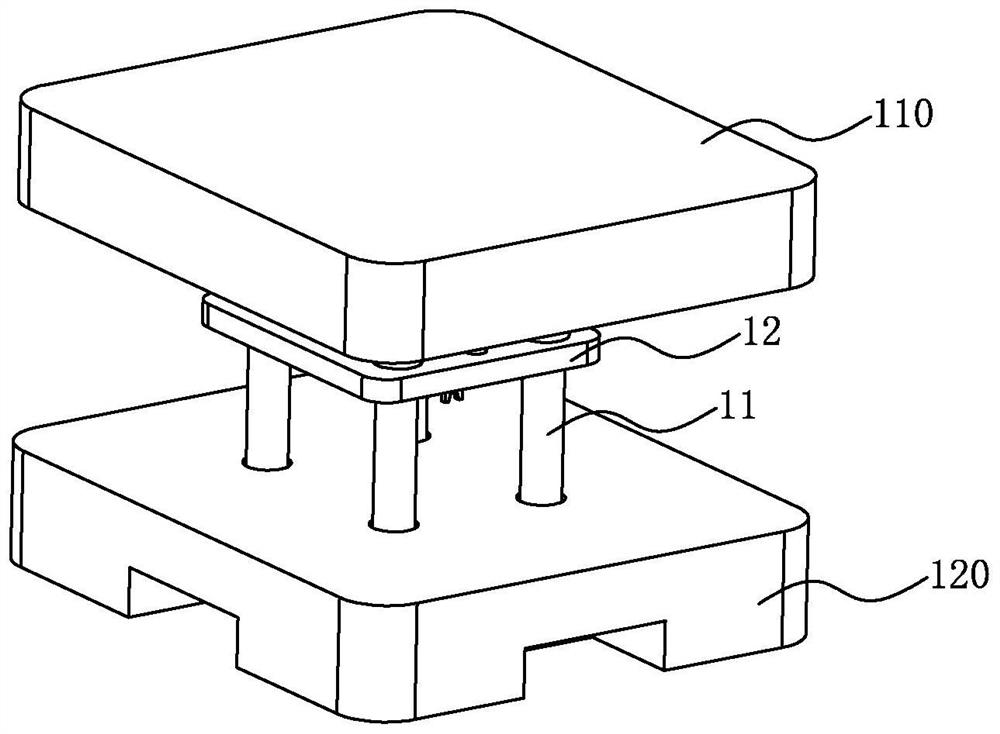

[0017] In order to further illustrate the technical means and effects adopted by the present invention, a detailed description will be given below in conjunction with a preferred embodiment of the present invention and its accompanying drawings.

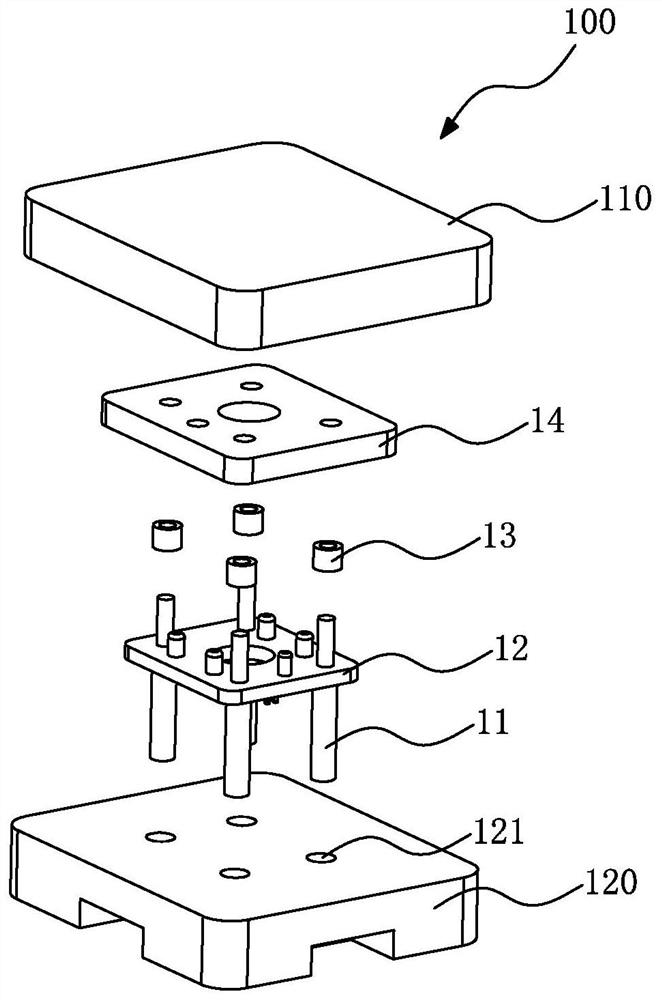

[0018] see figure 2 , figure 2 A schematic structural diagram of the disassembled state of the positioning and assembling jig of the present invention is shown.

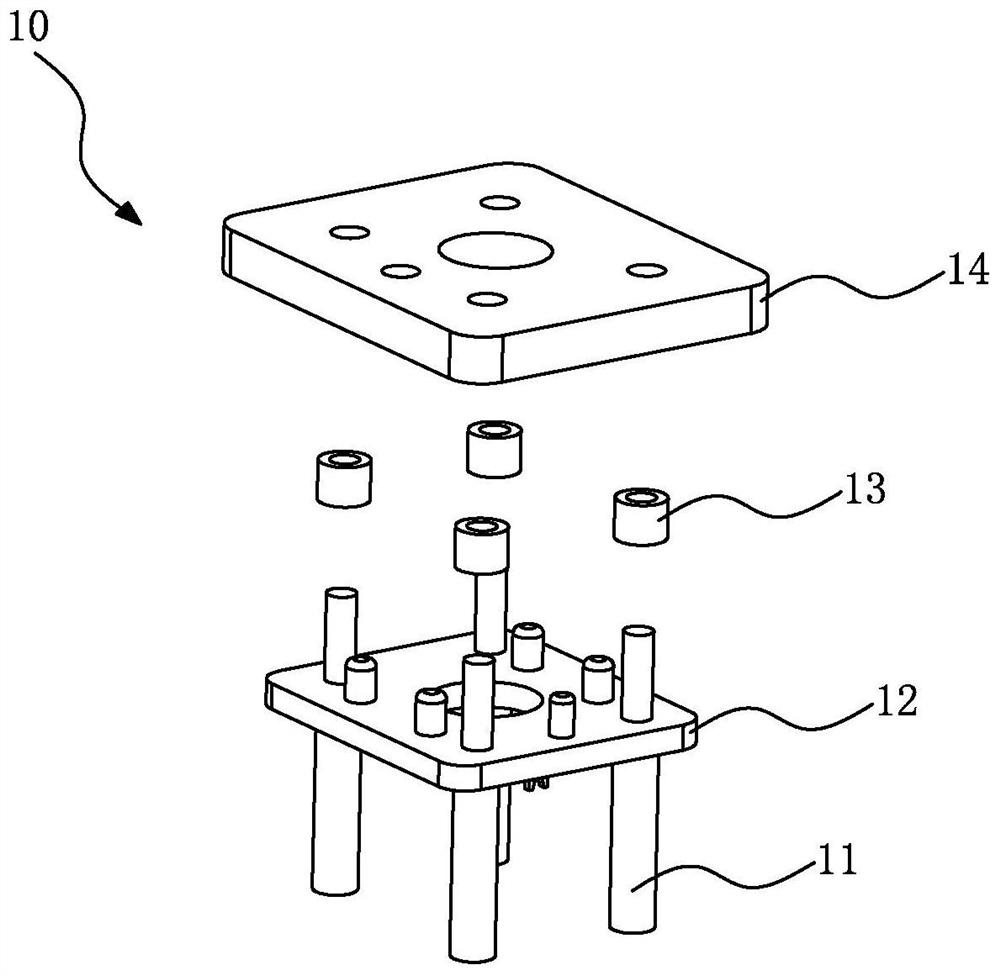

[0019] The purpose of the present invention is to provide a positioning assembly jig 100 for assembling an electronic product 10, the electronic product 10 includes four studs 11, a main board 12, four gasket sets 13 and a stud base 14, wherein The main board 12 is also provided with four first screw holes, and the stud base 14 is provided with four second screw holes, and the positions of the four second screw holes are the same as those of the four first screw holes. Correspondingly, the positioning assembly fixture includes:

[0020] An upper fixing plate 110, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com