Angle steel rolling guide device

A guide device and angle steel technology, which is applied in the field of steel rolling in the steel industry, can solve the problems of iron sheet sticking, scratches on the surface of the rolled piece, and the deflection angle of the finished product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In view of the prior art, in the process of angle steel production, the entrance guide of the rolling mill needs to be in contact with high-temperature steel parts, and due to its structural structure, it often causes quality defects such as surface scratches, scars, and finished product deflection. , the present invention provides an angle steel rolling guide device, and the present invention will be further described below in conjunction with specific embodiments.

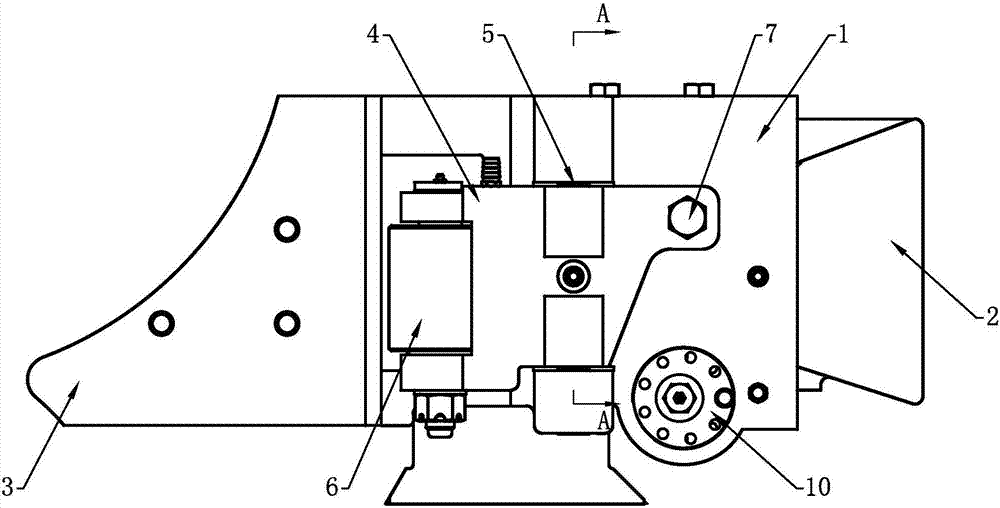

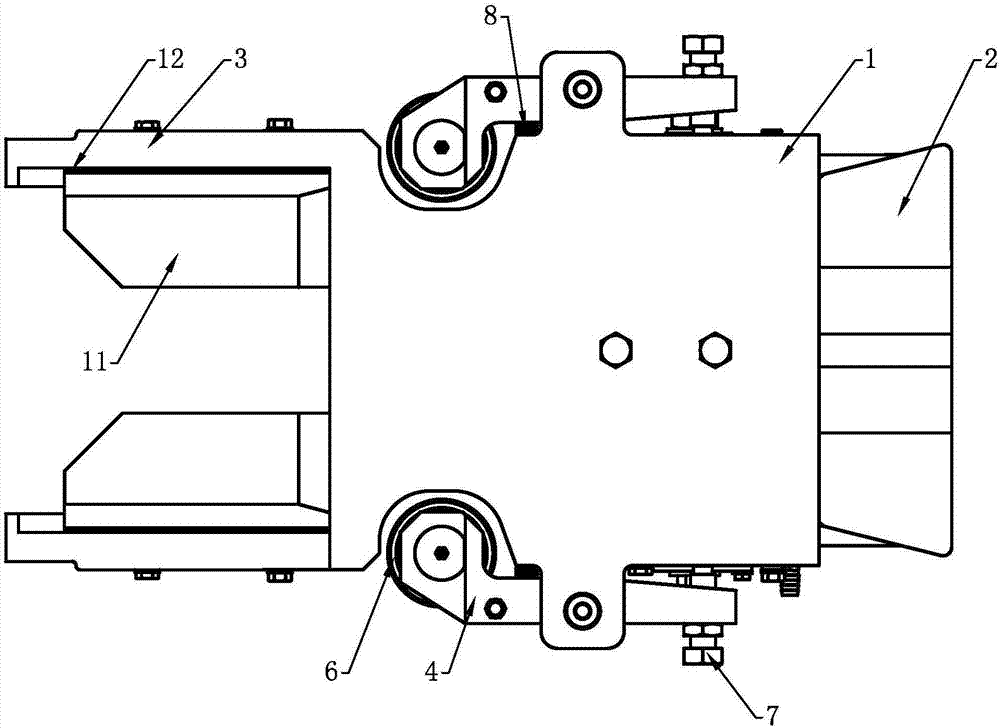

[0024] see Figure 1-Figure 5 , the angle steel rolling guide device in this embodiment includes:

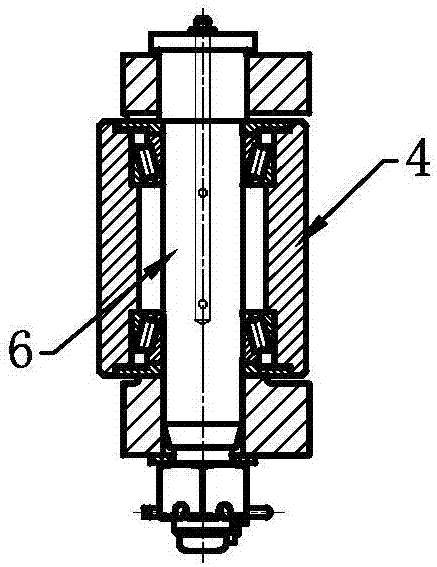

[0025] The guide box body 1 is provided with a vertical plate 3 and an inlet guide plate 2 on the left and right sides of the guide box body 1 respectively. , the vertical board 3 is integrally formed with the guide box body 1; two lining boards 11 are arranged between the two vertical boards 3, and a backing board 12 is arranged between the lining board 11 and the vertical board 3; A support arm 4 is resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com