Cement-based capillary crystalline waterproof coating and preparation method thereof

A osmotic crystalline waterproofing and cement-based technology, which is applied in the field of cement-based osmotic crystalline waterproofing coatings and its preparation, and waterproof engineering, can solve problems such as poor structure, weak adhesion, and poor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment provides a preparation process of cement-based permeable crystalline waterproof coating, which mainly includes the following steps:

[0056] one. Weigh raw materials: 685 kg of cement, 293 kg of quartz powder, 12 kg of methyl triethoxysilane, 10 kg of dehydrated ammonium aluminum sulfate; cement, quartz powder, methyl triethoxysilane, and dehydrated ammonium aluminum sulfate are all powder ;

[0057] Cement: Portland cement;

[0058] two. Preparation of powder

[0059] First put cement and quartz powder into the dry powder mixer, stir evenly, then add methyltriethoxysilane, stir for 30 minutes, then add dehydrated ammonium aluminum sulfate, stir for 10 minutes, and discharge to obtain powder-type cement Based penetrating crystalline waterproof coating.

[0060] Construction method:

[0061] When in use, it is first necessary to prepare: the coating according to the present embodiment: the mass ratio of water is 4~4.5:4~4.5, respectively weigh the...

Embodiment 2-14

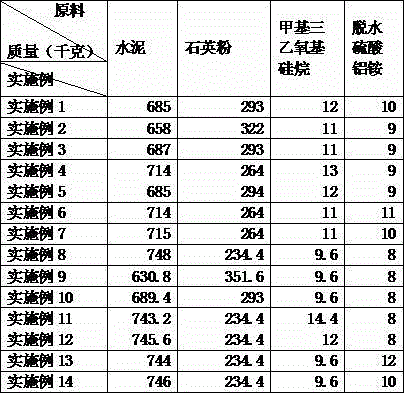

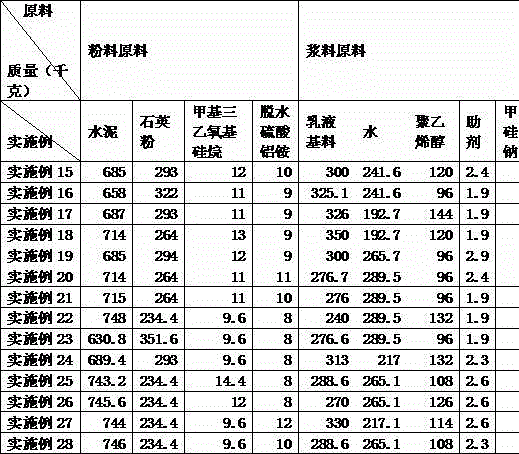

[0066] The raw materials and quality used in Examples 2-14 are shown in Table 1 below, and its preparation method and use (construction) method are the same as in Example 1; Table 1 below shows the specific materials used in Examples 1-14. Raw materials and quality. According to the requirements of GB18445-2001, the coatings of the various embodiments of the present invention are detected, and the following table 2 shows the detection data of the cement-based permeable crystalline waterproof coatings obtained in Examples 1-14. As can be seen from the detected data, this The invented cement-based osmotic crystalline waterproof coating has high strength, which is basically similar to cement. In addition, it has the function of osmosis and waterproof, so it is an ideal architectural waterproof coating.

[0067] Table 1

[0068]

[0069] Table 2

[0070] Test items Flexural strength 28d Compressive strength 28d Adhesive strength on wet substrate stability ...

Embodiment 15

[0072] This embodiment provides a preparation process of cement-based permeable crystalline waterproof coating, which mainly includes the following steps:

[0073] one. Weighing raw materials: 685 kg of cement, 293 kg of quartz powder, 12 kg of methyltriethoxysilane, 10 kg of dehydrated ammonium aluminum sulfate, 300 kg of emulsion base material, 241.6 kg of water, 120 kg of polyvinyl alcohol, 2.4 kg of additives , 3 kg of sodium methyl silicate; cement, quartz powder, methyltriethoxysilane, and dehydrated ammonium aluminum sulfate are powders;

[0074] Cement: Portland cement.

[0075] Emulsion base material: refers to the mixture of silicone rubber emulsion and VAE emulsion in any proportion. The so-called mixture of any proportion means that it can be any one of silicone rubber emulsion or VAE emulsion, or silicone rubber emulsion and VAE emulsion according to a certain proportion of the mixture;

[0076]Sodium methyl silicate: a sodium methyl silicate solution with a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com