Production method of high-purity aluminum oxide

A high-purity alumina and production method technology, applied in the direction of alumina/hydroxide, etc., can solve the problems of lengthening the production cycle and increasing production costs, and achieve the effects of low cost, simple production process, and easy control of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

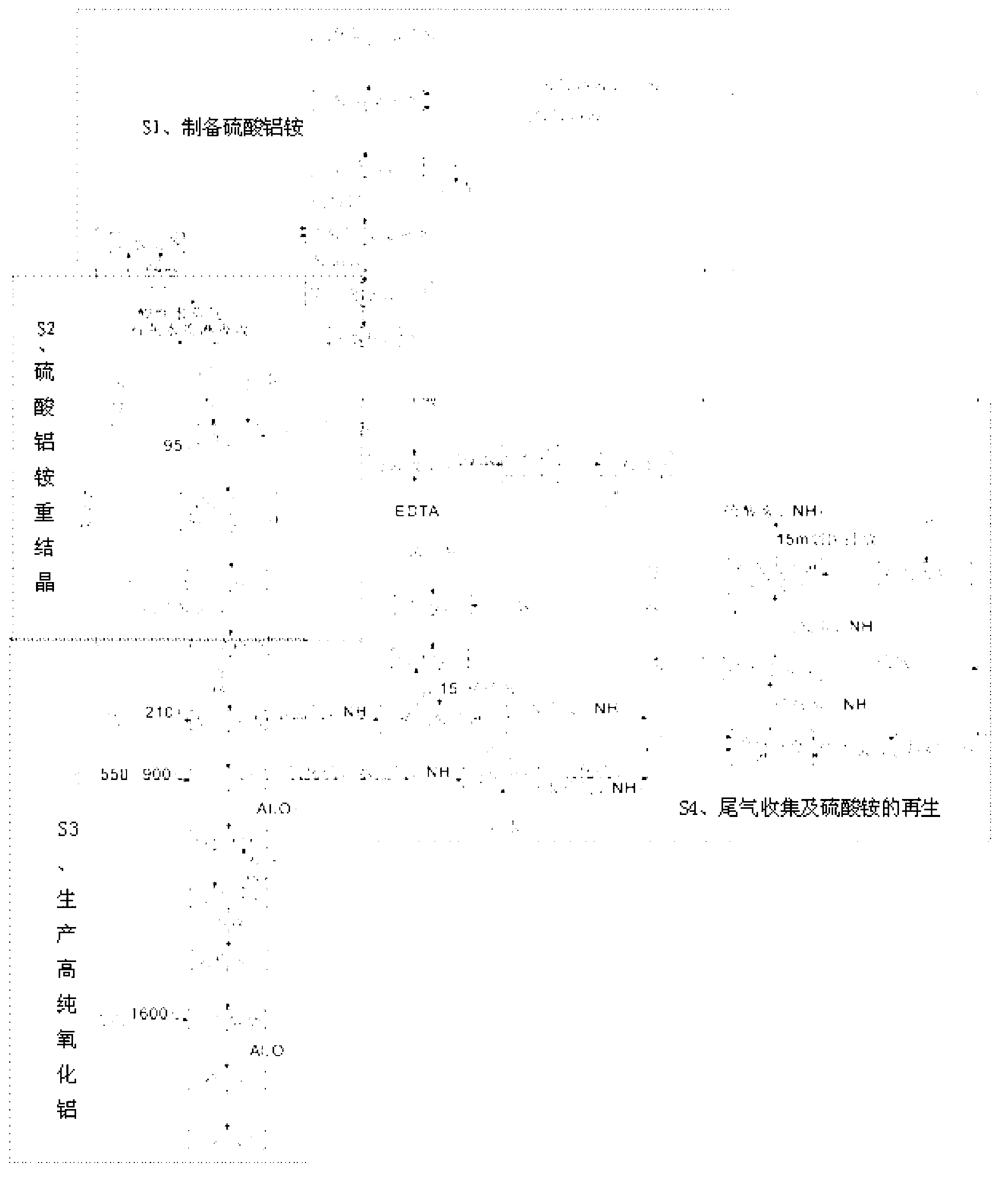

[0042] Please refer to figure 1 , the present invention provides a production method of high-purity alumina, comprising a high-purity alumina production system and a tail gas collection system, comprising the following steps:

[0043] S1, prepare aluminum ammonium sulfate:

[0044] First put aluminum hydroxide and 98% sulfuric acid into the reactor, and add the ammonium sulfate solution of the tail gas collection system and the sulfuric acid of the tail gas collection system into the reactor as supplementary acid and supplementary water to react together to produce aluminum sulfate and aluminum sulfate The mixed solution of ammonium; after being filtered through the filter cloth, it enters the aluminum ammonium sulfate reactor for reaction; the mixed solution is in the aluminum ammonium sulfate reactor, suppleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com