Polishing device and method for variable-stiffness grinding wheel assisted by magneto-rheological jet flow

A polishing device and magnetorheological technology, which are applied in grinding/polishing safety devices, grinding/polishing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problems of low polishing efficiency and complicated electromagnetic field control, etc. To reduce heat, improve polishing removal rate, avoid burns and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiments. The drawings are for exemplary description, which is merely a schematic diagram, rather than the experiment, and is not to be understood to be in this patent; in order to better illustrate the embodiments of the invention, there will be omitted, Enlarge or shrink does not represent the size of the actual product; some well-known structures and descriptions thereof may be understood in the drawings in the drawings.

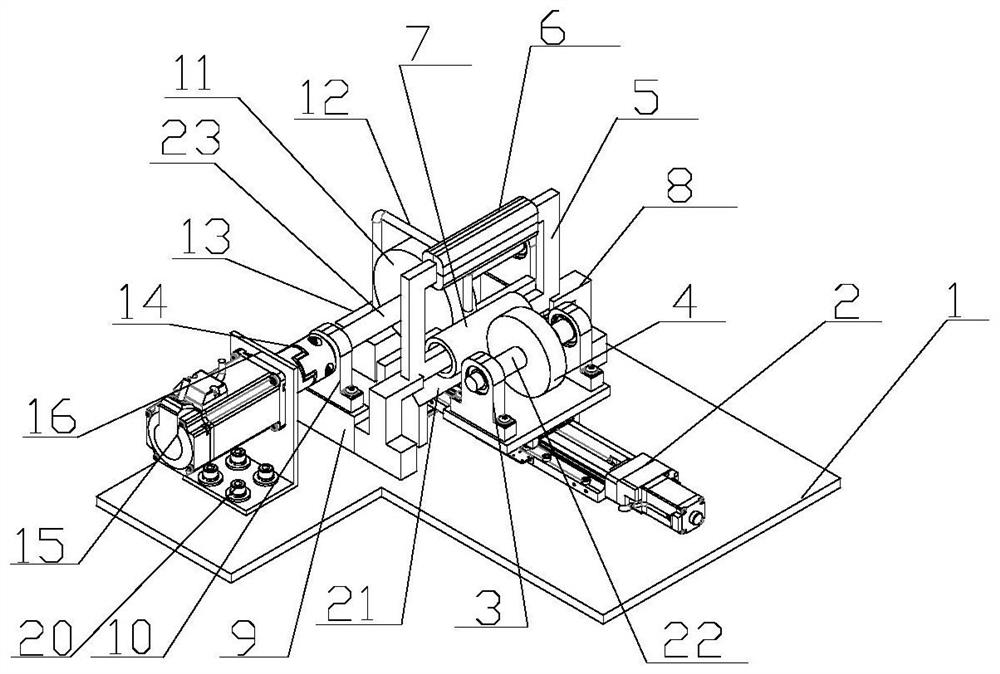

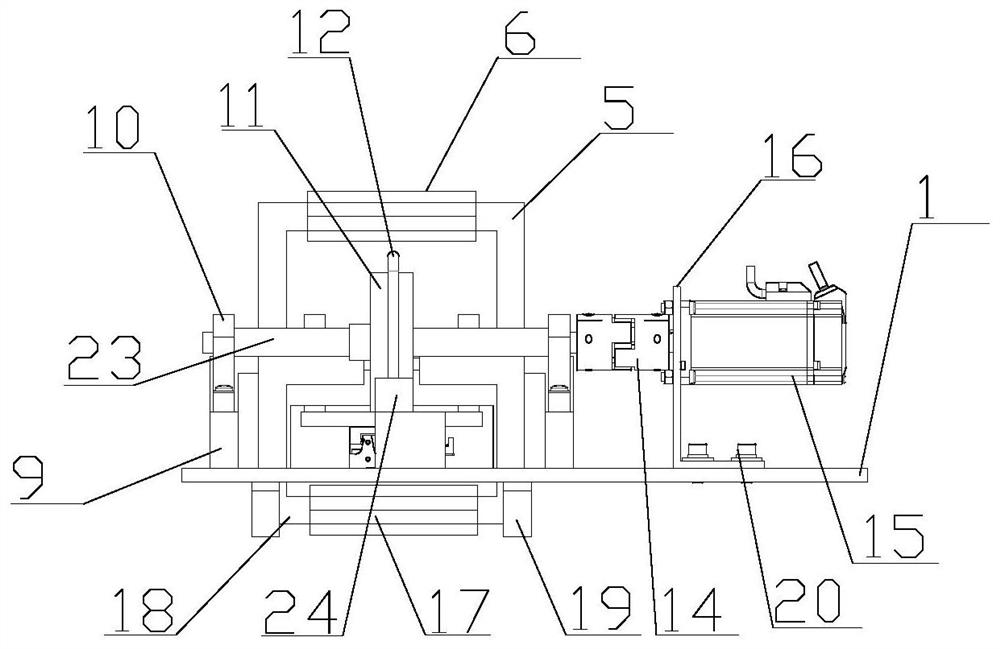

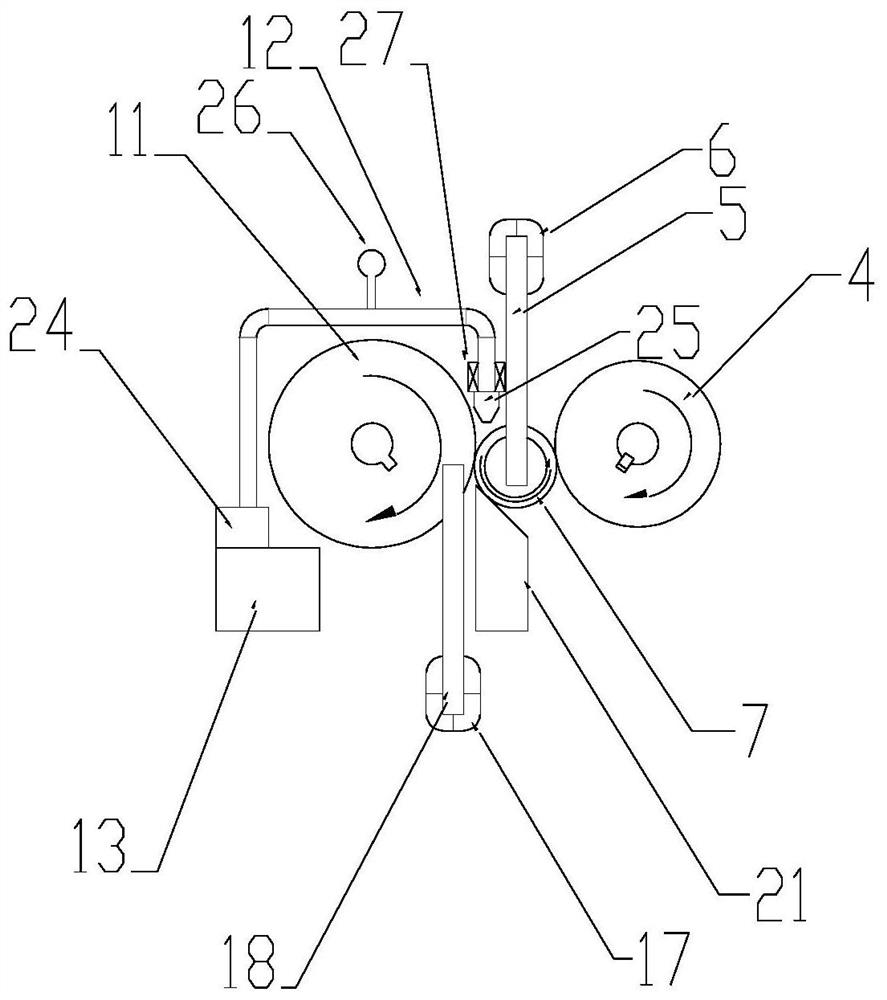

[0026] Such as Figure 1 to 3 The present invention is shown in the present invention, the polishing device of the present invention, including the bottom plate 1, the sliding guide rail module 2, No. 1 bearing housing 3, guide wheel 4, one core 5, No. 1 Coil 6, workpiece 7, core bracket 8, No. 2 bearing base 9, two bearing housing 10, magneto-flow elastic grinding wheel 11, catheter 12, magneto-flow polishing liquid storage box 13, joint The shaft 14, the motor 15, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com