Chemical mechanical polishing aqueous composite and chemical mechanical polishing process of titanium substrate

A water-based composition and chemical-mechanical technology, applied in the direction of polishing compositions containing abrasives, etc., can solve problems that need to be improved, achieve the effects of reducing surface defects and particle residues, improving polishing removal efficiency, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

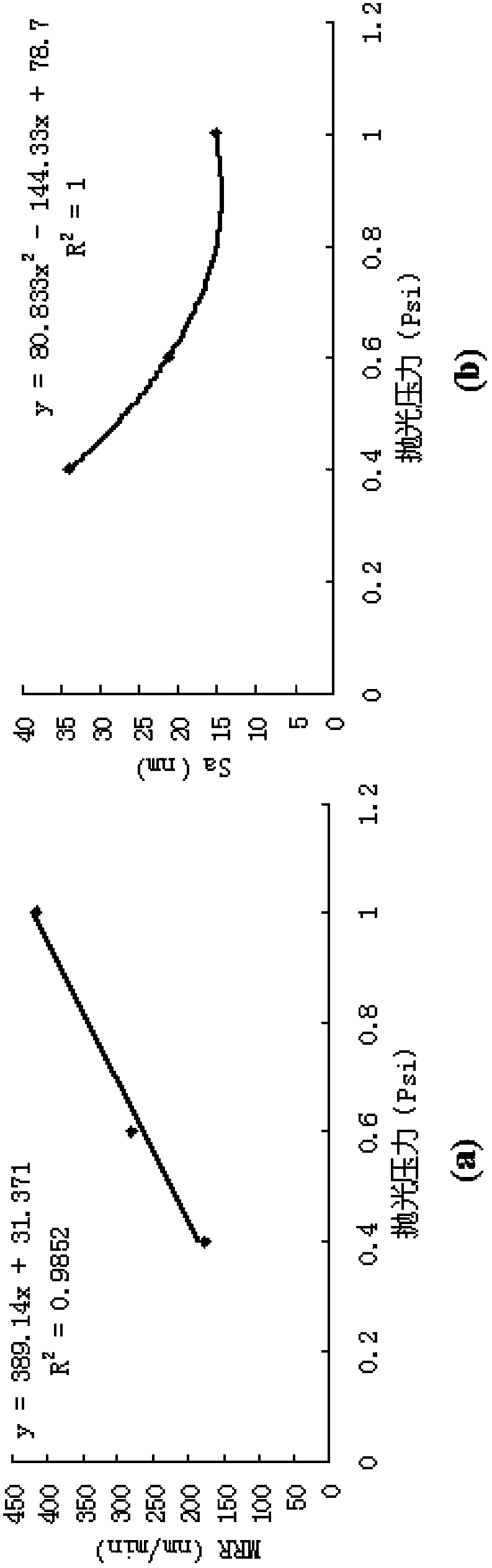

[0041] Example 1 Influence of the change of polishing liquid and polishing pressure on the polishing effect during the initial polishing process

[0042] According to the conditions described in the following experimental groups and control groups, the initial polishing experiment of the titanium substrate was carried out respectively, and then the polishing effects of each group were compared:

[0043] 1. Grouping and processing methods

[0044] Experimental group 1:

[0045] Add 20 grams of 2-phosphonobutane-1,2,4-tricarboxylic acid, 10 grams of lactic acid (corrosion inhibitor film-forming agent), and 10 grams of ammonium fluoride (complexing agent) into 500 grams of deionized water in sequence, Stir to dissolve, and then stir slowly to add 187 grams of 30% 25nm silica hydrosol (abrasive).

[0046] Before polishing, add 60 grams of 30% oxidant hydrogen peroxide solution to the above mixture, and wash with H 2 SO 4 Calibrate its pH value to 3.0, and finally add water t...

Embodiment 2

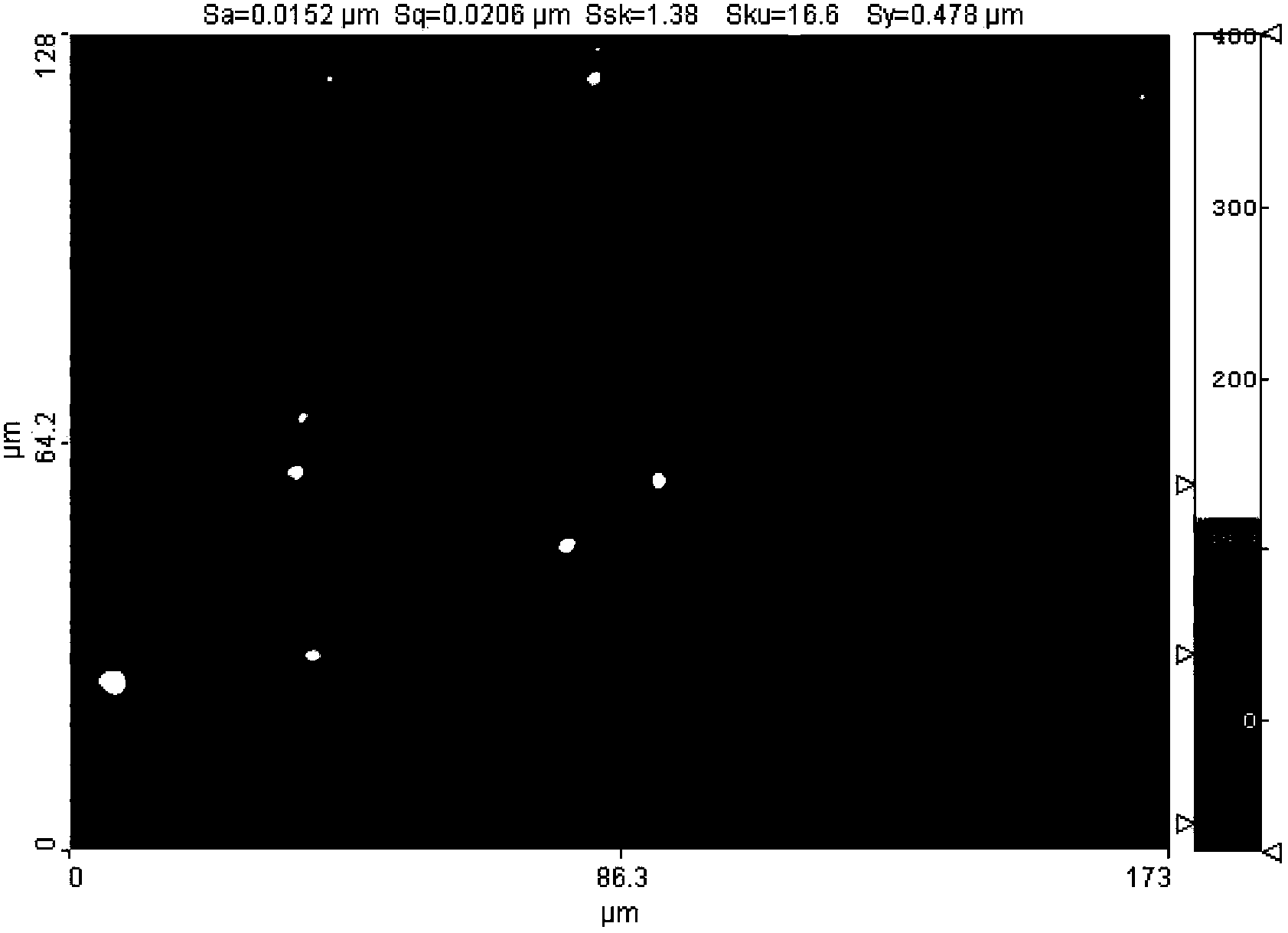

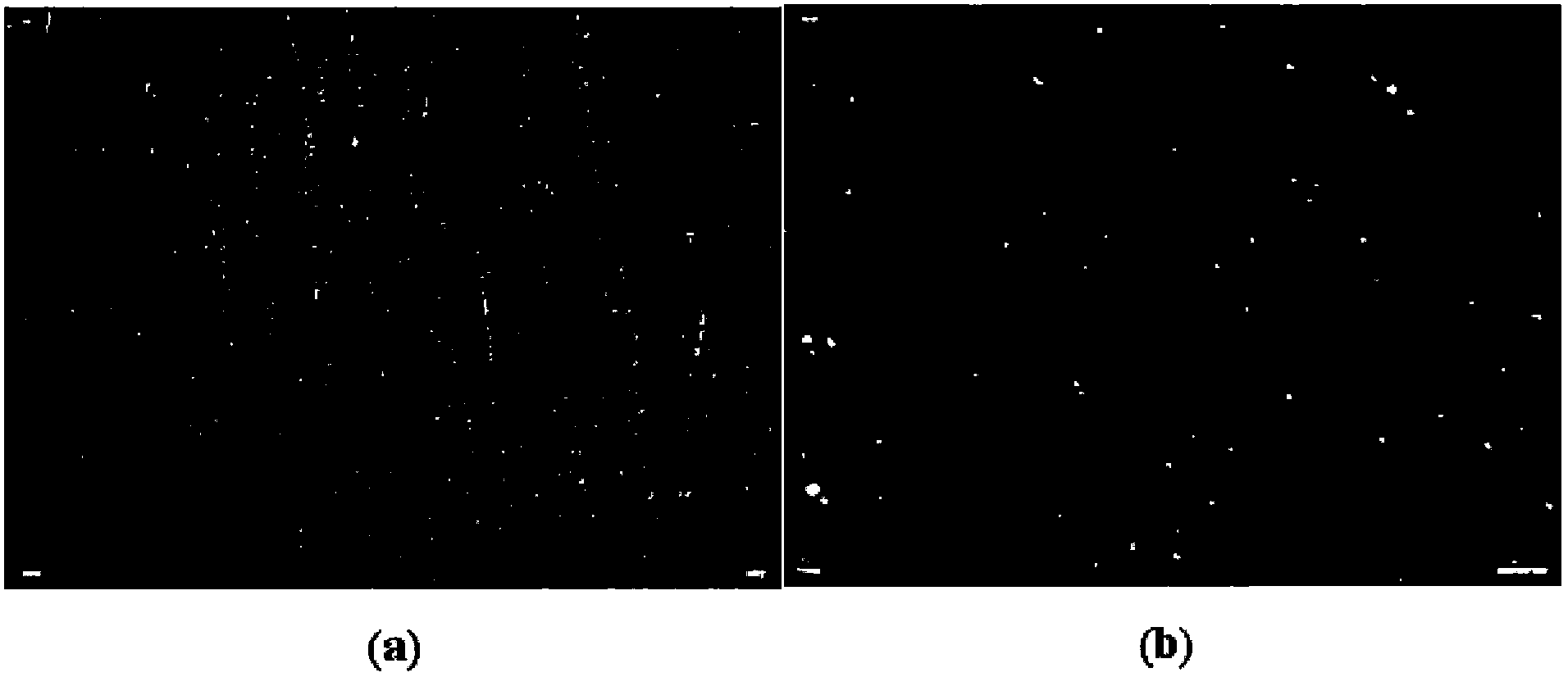

[0064] Influence of the composition and pH value of the chemical mechanical polishing aqueous composition on the polishing effect in the process of embodiment 2 fine polishing

[0065] According to the conditions described in the following experimental groups and control groups, the titanium substrates after the initial polishing were respectively finely polished, and then the polishing effects of each group were compared:

[0066] 1. Grouping and processing methods

[0067] Experimental group 1:

[0068] Add 20 grams of 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA), 10 grams of lactic acid (LA) (corrosion inhibitor film-forming agent), and 10 grams of ammonium fluoride (complexing agent) in sequence 500 grams of deionized water, stir to dissolve, evenly stir slowly and add 187 grams of 30% 25nm silica hydrosol (abrasive).

[0069] Before polishing, add 60 grams of 30% oxidant hydrogen peroxide solution to the above mixture, and wash with H 2 SO 4 Calibrate its pH v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com