a polishing composition

A polishing composition and composition technology, applied in the field of polishing compositions for sapphire, can solve the problems of low production efficiency, difficult processing, high processing cost, etc., and achieve the effects of improving surface quality, high polishing removal rate, and increasing removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

[0018] A polishing composition for sapphire, comprising mixed abrasives, inorganic metal salts, surfactants, pH regulators and water.

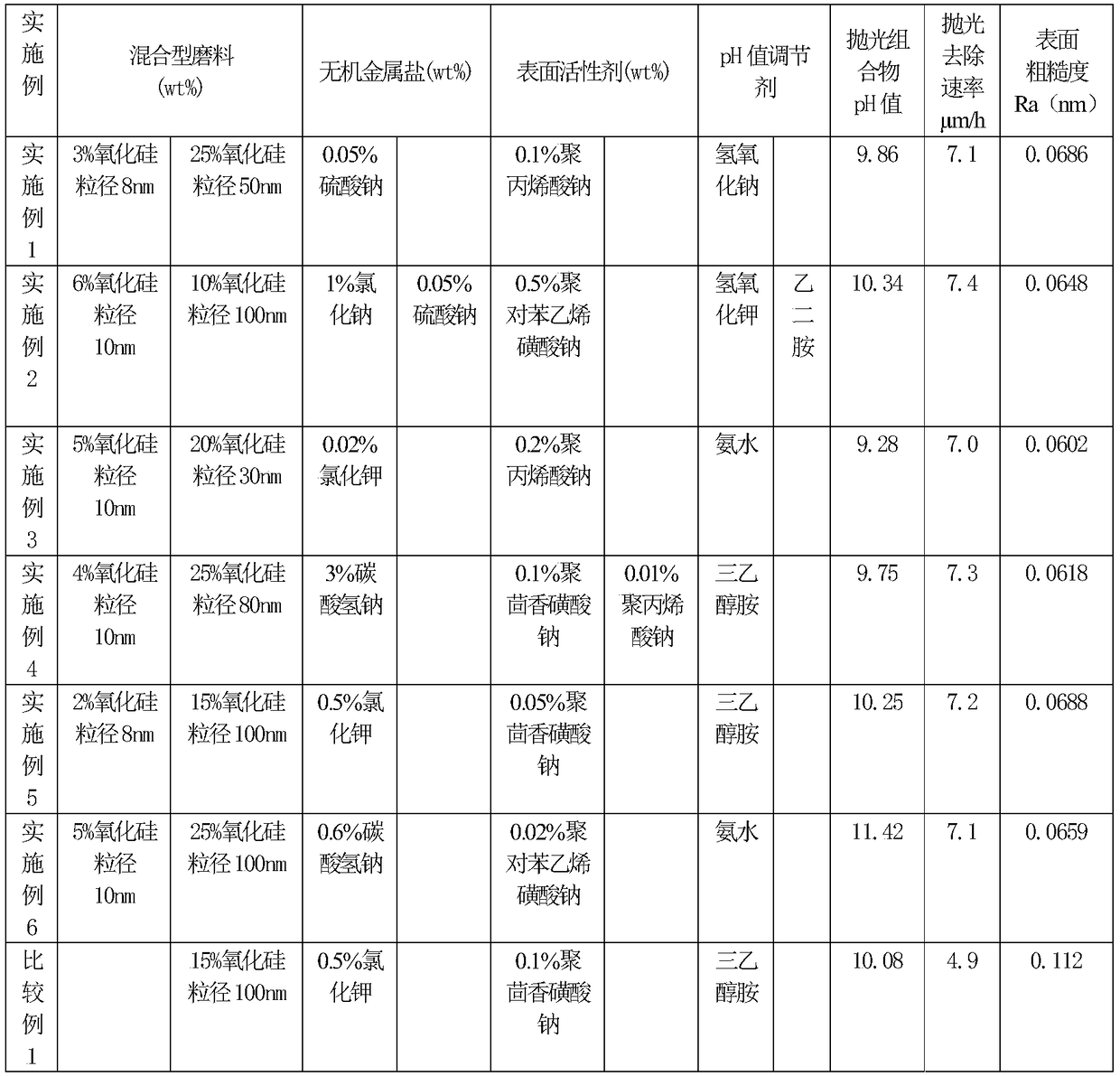

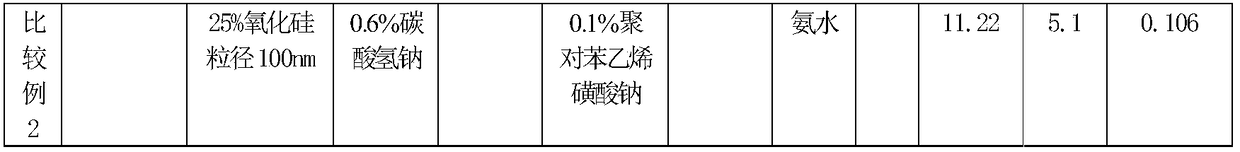

[0019] Table 1 shows the polishing compositions of Examples 1-6 and Comparative Examples 1-2 and their cyclic removal rates and surface quality and surface roughness Ra after polishing sapphire wafers.

[0020] Polishing machine: UNIPOL-1000S single-sided polishing machine;

[0021] Polished sapphire wafer: 2 inches;

[0022] Polishing pad: SUBA800;

[0023] Polishing pressure: 300 g / cm2;

[0024] Upper plate speed: 60 rpm;

[0025] Bottom plate speed: 140 rpm;

[0026] Polishing fluid flow: 70ml / min

[0027] Polishing liquid circulation polishing time: 2 hours

[0028] Circular polishing: refers to that during the polishing process, the export port of the polish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com