Polishing composition, and preparation and polishing methods thereof

A polishing composition and composition technology, applied in the direction of polishing compositions containing abrasives, manufacturing tools, metal processing equipment, etc., can solve the problems of complex polishing methods, low removal rate, and insufficient surface smoothness, and achieve cycle Good polishing performance and high polishing removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

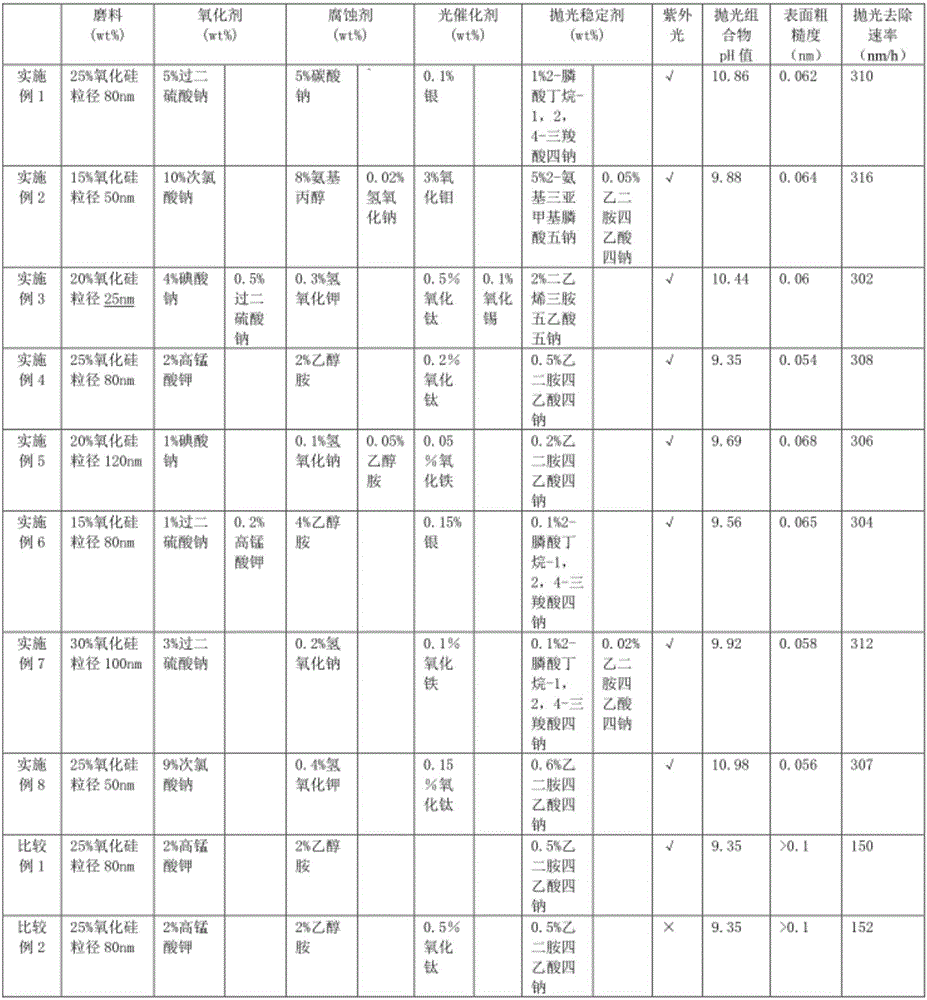

Embodiment 1~8

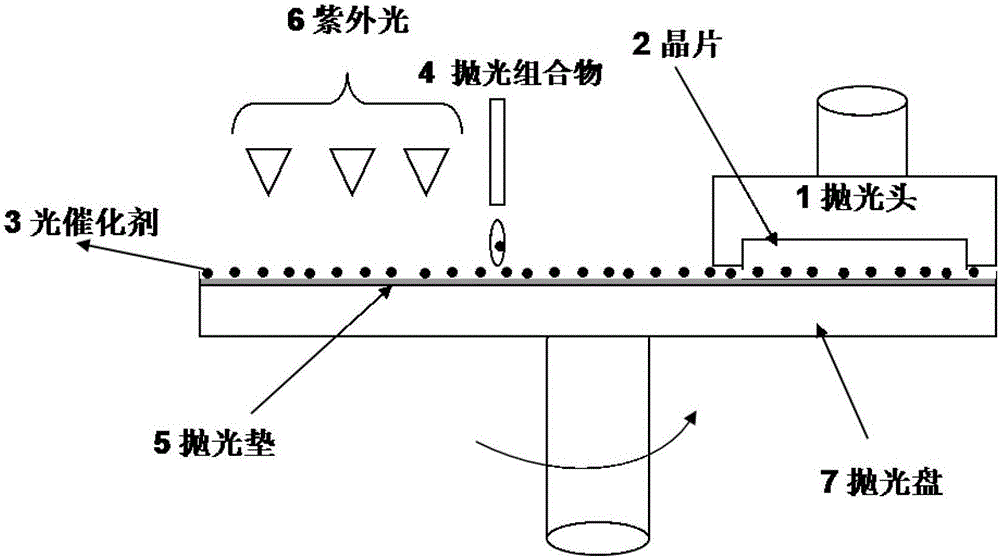

[0035] Examples 1-8 irradiated ultraviolet light on the polishing composition on the polishing pad, and Comparative Example 2 did not irradiate ultraviolet light on the polishing composition on the polishing pad;

[0036] The polisher is activated and the polishing pad moves relative to the silicon carbide wafer to achieve material removal.

[0037] The polishing conditions are as follows:

[0038] Polishing machine: Shenyang Kejing 1000S single-sided polishing machine;

[0039] Polished wafer: Si side of 2-inch 4H-SiC silicon carbide wafer;

[0040] Polishing pad: SUBA600;

[0041] Polishing pressure: 400 g / cm2;

[0042] Workpiece speed: 60 rpm;

[0043] Bottom plate speed: 140 rpm;

[0044] Polishing fluid flow: 70ml / min

[0045] Polishing liquid circulation polishing time: 1 hour

[0046] Circular polishing: refers to that during the polishing process, the export port of the polishing composition is connected with the import port, and the polishing composition repeat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com