Device and method for continuously preparing tetramethylammonium hydroxide

A technology of tetramethylammonium hydroxide and cathode, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of high production cost and high impurity content, and achieve high production cost and low impurity content. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

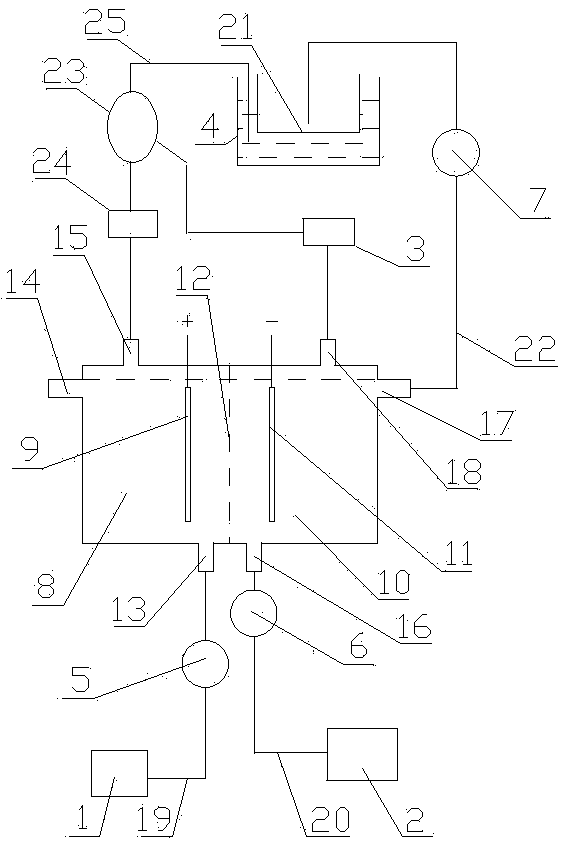

Image

Examples

Embodiment 1

[0035] Preparation of raw material anolyte: Weigh 28kg of tetramethylammonium bicarbonate, add 72kg of water to it, and configure 100kg of tetramethylammonium bicarbonate solution, the mass concentration of the tetramethylammonium bicarbonate solution is 28%.

[0036] Preparation of raw catholyte: Weigh 7kg of tetramethylammonium hydroxide, add 93kg of water to it, and configure 100kg of tetramethylammonium hydroxide solution, the mass concentration of the tetramethylammonium hydroxide solution is 7%.

[0037] The production process is shown below.

[0038] (1) Initialization: The raw material anolyte is dialyzed by the H-type cation exchange column and then added to the anode chamber, and the raw catholyte is added to the cathode chamber at the same time, and then the anode electrode and the cathode electrode are respectively connected to direct current for constant current electrolysis. The current density of current electrolysis is 0.3KA / m 2 , electrolyze for 1.5h, and com...

Embodiment 2

[0043] The tetramethylammonium bicarbonate solution with a mass concentration of 30% is used as the raw material anolyte, and the tetramethylammonium hydroxide solution with a mass concentration of 10% is used as the raw material catholyte.

[0044] The production process is shown below.

[0045] (1) Initialization: Add the raw anolyte to the anode chamber after being dialyzed by the ion exchange column, and add the raw catholyte to the cathode chamber at the same time, then connect the anode electrode and the cathode electrode to direct current respectively for constant current electrolysis and constant current electrolysis The current density is 0.35KA / m 2 , electrolysis for 2 hours, and the initialization process is completed, wherein the oxygen and carbon dioxide (ie anode gas) generated in the anode chamber enter the anode gas storage tank through the anode gas outlet pipe, and the hydrogen gas generated by the cathode enters the cathode gas storage tank through the catho...

Embodiment 3

[0050] The tetramethylammonium bicarbonate solution with a mass concentration of 32% is used as the raw material anolyte, and the tetramethylammonium hydroxide solution with a mass concentration of 12% is used as the raw material catholyte.

[0051] The production process is shown below.

[0052] (1) Initialization: The raw material anolyte is dialyzed by the H-type cation exchange column and then added to the anode chamber, and the raw catholyte is added to the cathode chamber at the same time, and then the anode electrode and the cathode electrode are respectively connected to direct current for constant current electrolysis. The current density of current electrolysis is 0.38KA / m 2 , electrolysis for 1.8h, and the initialization process is completed, wherein the oxygen and carbon dioxide (ie anode gas) generated in the anode chamber enters the anode gas storage tank through the anode gas outlet pipe, and the hydrogen gas generated by the cathode enters the cathode gas stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com