Method for preparing electronic-grade tetramethylammonium hydroxide (TMAH)

A technology of tetramethyl ammonium hydroxide and tetramethyl ammonium bicarbonate, applied in the field of electrochemistry, can solve the problems of low product purity and current efficiency of tetramethyl ammonium hydroxide, achieve low process energy consumption, and expand the scope of application , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

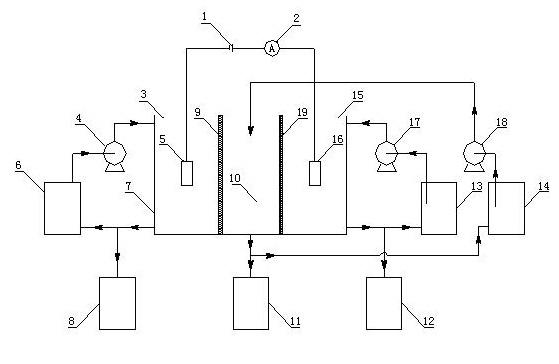

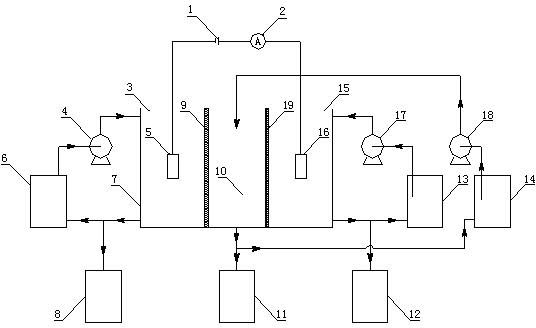

Method used

Image

Examples

Embodiment 1

[0030] In the double-membrane electrolysis device, the electrolytic cell body is made of polypropylene (PP), the cathode is made of 304 stainless steel, the anode is made of titanium-based ruthenium dioxide, the anion membrane is made of quaternized polyethersulfone anion exchange membrane, and the cation membrane is made of F4403D. Add 0.2-0.5 mol / L TMAH solution to the cathode tank, add 2.0 mol / L TMAHCO to the buffer tank 3 solution, add 0.4 mol / L Na to the anode tank 2 SO 4 solution, the electrolysis temperature is 40-60 ℃, and the electrolysis current density is 400, 500, 600, 800 and 1000 A / m 2 , to electrolyze the solution.

[0031] At the end of the electrolysis, according to the test results of the product, the current efficiency of the electrolysis process was calculated, and the results were: 80.6%, 80.9%, 83.7%, 84.9% and 80.2%, and the total metal ion content in the product was lower than 4 ppm. It can be seen that when the current density is greater than 800 A / ...

Embodiment 2

[0033] The electrolytic cell body, cathode and anode, anion and cation exchange membranes in Example 1 were used. Add 0.2-0.5 mol / L TMAH solution into the cathode tank, the electrolysis temperature is 40-60 ℃, and the electrolysis current density is 800 A / m 2 , add 0.4 mol / L Na to the anode tank 2 SO 4 solution, add 1.0, 1.5, 2.0, 2.5, 3.0 mol / L TMAHCO into the buffer tank 3 The solution is electrolyzed.

[0034] At the end of the electrolysis, according to the test results of the product, the current efficiency of the electrolysis process was calculated, and the results were: 83.6%, 86.2%, 83.9%, 82.1% and 81.5%, and the total metal ion content in the product was lower than 4 ppm. It can be seen that when TMAHCO in the buffer tank 3 When the solution concentration is greater than 1.5 mol / L, the electrolysis efficiency of the process begins to decline. Therefore, the TMAHCO in the buffer tank during electrolysis 3 The solution concentration is preferably 1.5 mol / L, and t...

Embodiment 3

[0036] The electrolytic cell body, cathode and anode, anion and cation exchange membranes in Example 1 were used. Add 0.2-0.5 mol / L TMAH solution to the cathode tank, add 0.4 mol / L NaH solution to the anode tank 2 SO 4 solution, TMAHCO in buffer tank 3 The solution concentration is 1.5 mol / L, and the electrolytic current density is 800 A / m 2 , the temperature during electrolysis is controlled at 40, 45, 50, 55, and 60 °C, and the solution is electrolyzed.

[0037] At the end of the electrolysis, according to the test results of the product, the current efficiency of the electrolysis process was calculated, and the results were: 80.1%, 87.9%, 87.3%, 84.6% and 82.5%, and the total metal ion content in the product was lower than 4 ppm. It can be seen that when the temperature of electrolysis is higher than 45 °C,

[0038] The electrolysis efficiency of the process starts to drop. Therefore, the temperature during electrolysis is preferably 45 °C, and a higher current efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com