Preparation method of monolayer manganese dioxide nano-plates

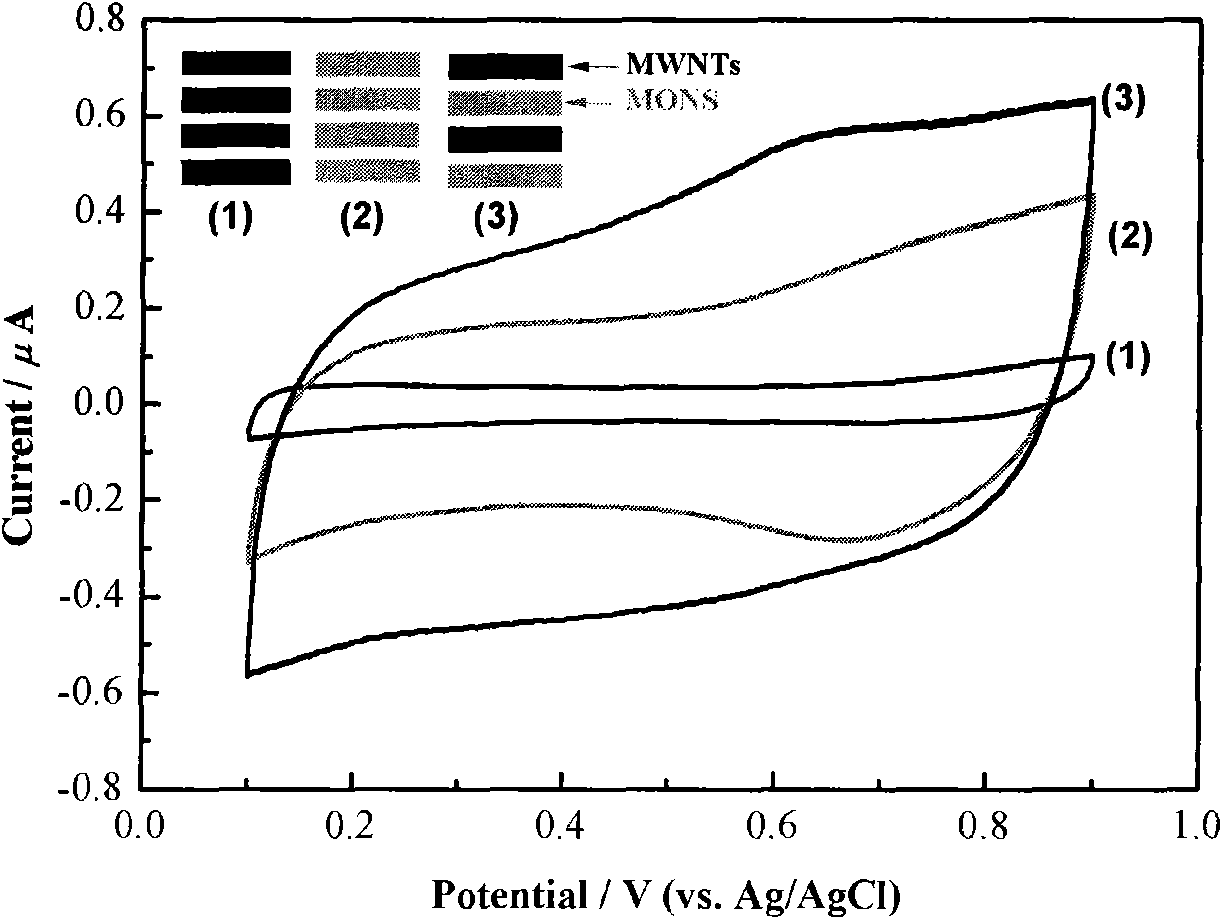

A technology of manganese dioxide and nanosheets, which is applied in the direction of manganese oxide/manganese hydroxide, electrical components, electrolytic capacitors, etc., can solve the problems of multi-layer materials and easy agglomeration, and achieve the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

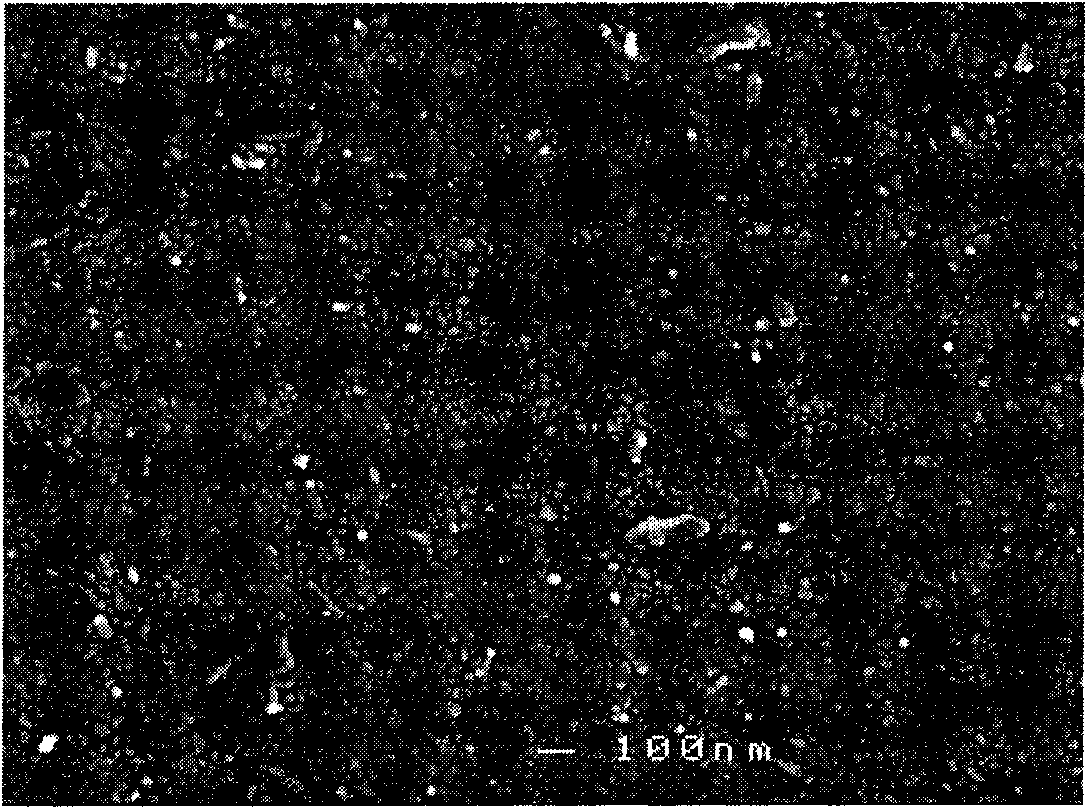

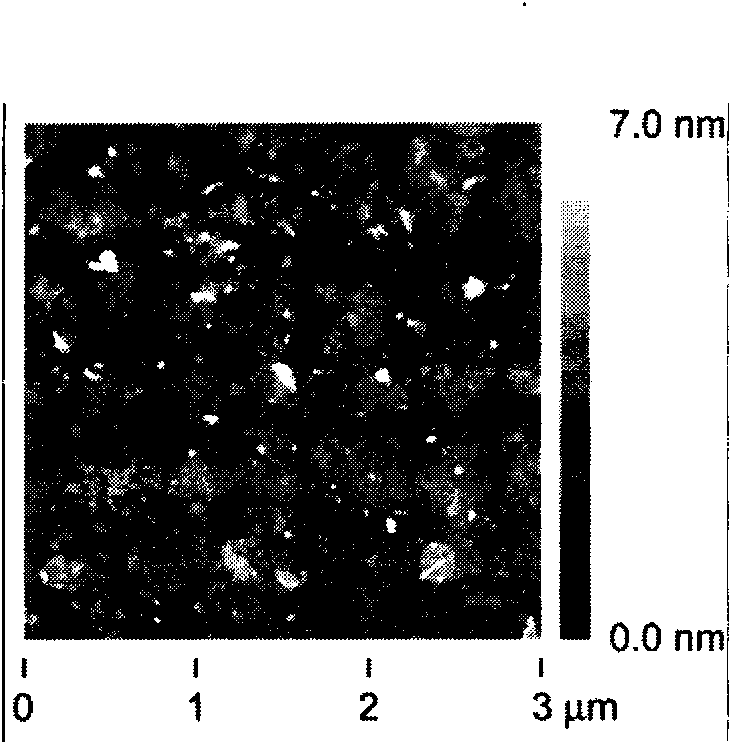

[0025] Pour 100ml of 0.6M sodium hydroxide solution containing 3wt% hydrogen peroxide into 50ml of 0.3M manganese nitrate solution, stir for 30 minutes and let it stand for 5 hours, filter off the supernatant to obtain a precipitate, and wash it with deionized water.

[0026] Take 1 gram of the precipitate and put it into 100ml of 2M sodium hydroxide solution and stir for 5 minutes, then put it into an autoclave and heat it at 150° C. for 24 hours. After washing with deionized water and filtering to obtain the ordered layered structure of OH x MnO 2 .

[0027] put the obtained OH x MnO 2 Add it to 500ml of 0.1M hydrochloric acid solution and stir for 20 hours; filter the precipitate and add it to 500ml of 0.1M hydrochloric acid solution again and stir for 20 hours. Precipitate with a high-speed centrifuge to obtain H x MnO 2 .

[0028] Take 0.2 g H x MnO 2 Put into 50ml 0.2M tetrabutylammonium hydroxide solution and shake for 48 hours to obtain suspended single-shaped...

Embodiment 2

[0031] Pour 100ml of 0.6M sodium hydroxide solution containing 2wt% hydrogen peroxide into 50ml of 0.3M manganese nitrate solution, stir for 30 minutes and then let it stand for 5 hours, filter off the supernatant to obtain a precipitate, and wash it with deionized water.

[0032] Take 1 gram of the precipitate and put it into 100ml of 2M sodium hydroxide solution and stir for 5 minutes, then put it into an autoclave and heat it at 150° C. for 24 hours. After washing with deionized water and filtering to obtain the ordered layered structure of OH x MnO 2 .

[0033] put the obtained OHx MnO 2 Add it to 500ml of 0.1M hydrochloric acid solution and stir for 20 hours; filter the precipitate and add it to 500ml of 0.1M hydrochloric acid solution again and stir for 20 hours. Precipitate with a high-speed centrifuge to obtain H x MnO 2 .

[0034] Take 0.4 g H x MnO 2 Put into 50ml 0.2M tetramethylammonium hydroxide solution and shake for 48 hours to obtain suspended single-sh...

Embodiment 3

[0037] Pour 100ml of 0.6M sodium hydroxide solution containing 2wt% potassium permanganate into 50ml of 0.3M manganese nitrate solution, stir for 30 minutes and let it stand for 5 hours, filter the supernatant to obtain a precipitate, and wash it with deionized water .

[0038] Take 1 gram of the precipitate and put it into 100ml of 2M sodium hydroxide solution and stir for 5 minutes, then put it into an autoclave and heat it at 150° C. for 24 hours. After washing with deionized water and filtering to obtain the ordered layered structure of OH x MnO 2 .

[0039] put the obtained OH x MnO 2 Add it to 500ml of 0.1M hydrochloric acid solution and stir for 20 hours; filter the precipitate and add it to 500ml of 0.1M hydrochloric acid solution again and stir for 20 hours. Precipitate with a high-speed centrifuge to obtain H x MnO 2 .

[0040] Take 0.4 g H x MnO 2 Put into 50ml 0.2M tetramethylammonium hydroxide solution and shake for 48 hours to obtain suspended single-sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com