TiO2/ZIF-8 nanocomposite with core-shell structure and preparation method of TiO2/ZIF-8 nanocomposite

A nanocomposite material, ZIF-8 technology, applied in the direction of separation methods, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of poor adsorption performance, achieve mild preparation conditions, and process Simple, great application potential for effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Add 1.36g tetrabutyl titanate to 20L ethylene glycol solution, stir evenly at room temperature for 24 hours, then add it to anhydrous acetone, stir rapidly for 10 minutes and then let stand for 1 hour; centrifuge the white suspension, water and ethanol washing and drying to obtain uniform TiO 2 Amorphous nanospheres; then these powders were added to 20% tetramethylammonium hydroxide aqueous solution, reacted at 160°C for 48h, and finally centrifuged, washed with water and ethanol and dried to obtain TiO 2 nanospheres.

[0032] (2) The prepared TiO 2 0.1 g of pellets was added to 40 mL of Zn(NO 3 ) 2 ·6H 2 Stir in O methanol solution for 0.5h, then add 40mL of 2-methylimidazole methanol solution with a molar concentration of 0.2mol / L, continue to stir for 1h, centrifuge, wash with water and ethanol and dry to obtain TiO 2 / ZIF-8 core-shell structure nanocomposites.

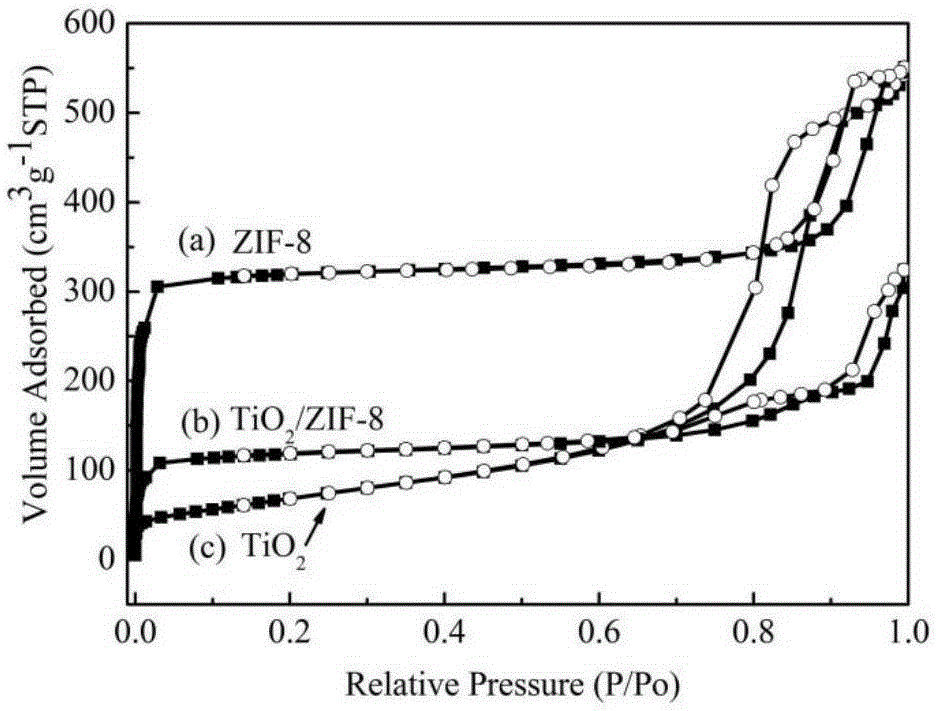

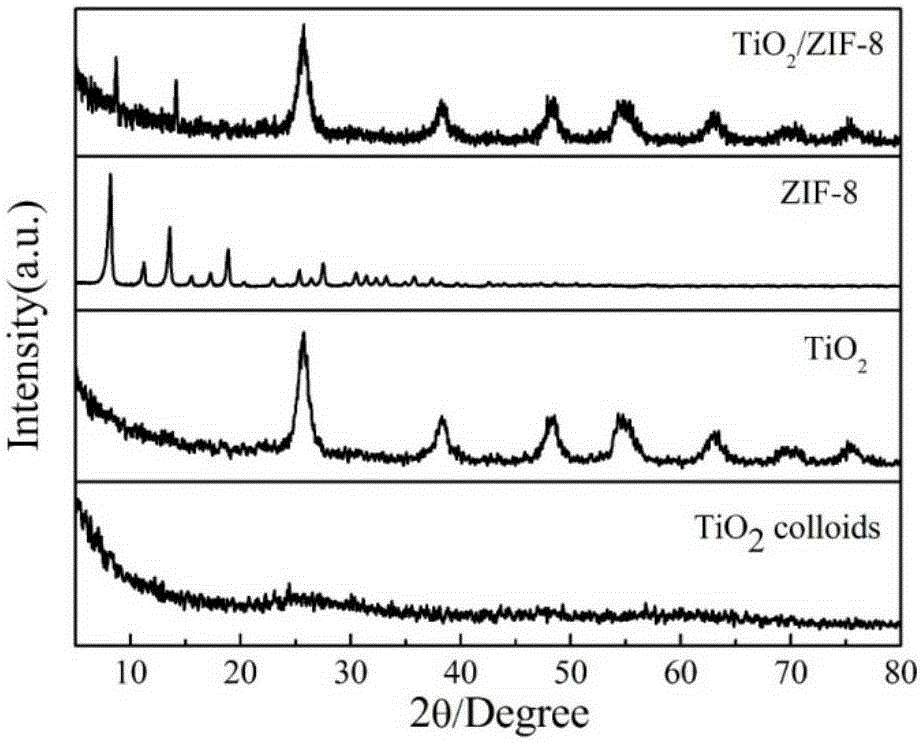

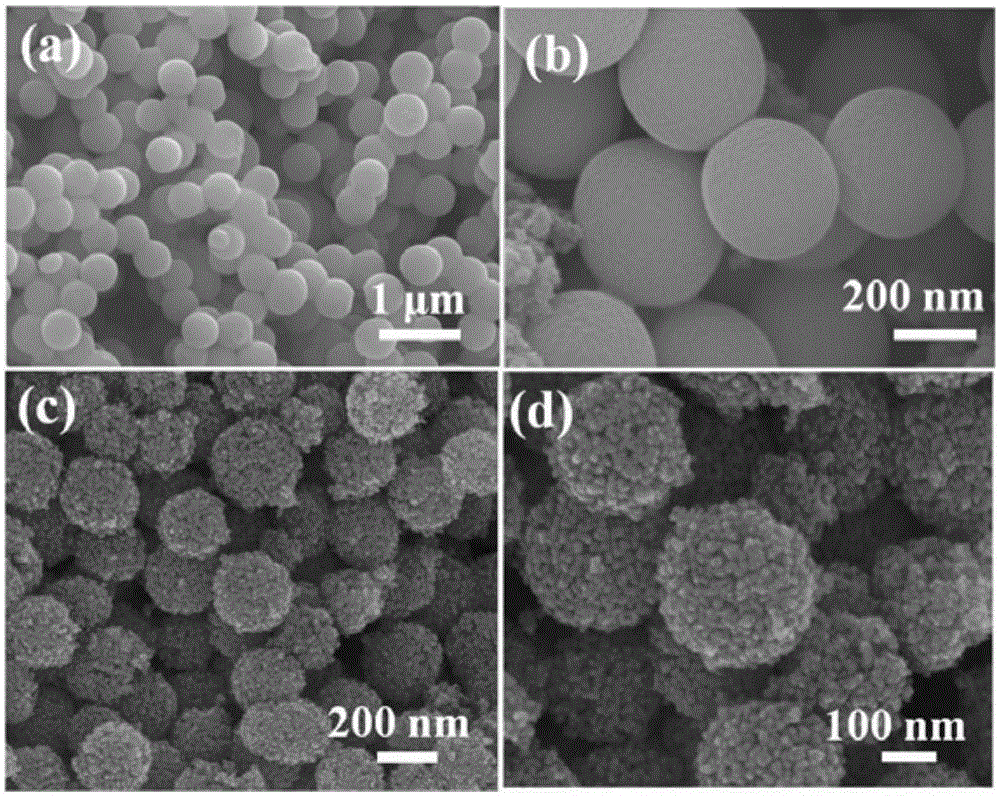

[0033] Products were analyzed using X-ray diffraction (XRD), scanning electron microscopy (SEM...

Embodiment 2

[0040] (1) Add 10.21g tetrabutyl titanate to 20L ethylene glycol solution, stir evenly at room temperature for 12 hours, then add it to anhydrous acetone, stir rapidly for 30 minutes and then let stand for 2 hours; centrifuge the white suspension, water and ethanol washing and drying to obtain uniform TiO 2 Amorphous nanospheres; then these powders were added to 30% tetramethylammonium hydroxide aqueous solution, reacted at 200°C for 24h, and finally centrifuged, washed with water and ethanol and dried to obtain TiO 2 nanospheres.

[0041] (2) The prepared TiO 2 0.1 g of pellets was added to 40 mL of Zn(NO 3 ) 2 ·6H 2 Stir in O methanol solution for 1 h, then add 40 mL of 2-methylimidazole methanol solution with a molar concentration of 0.08 mol / L, continue stirring for 4 h, centrifuge, wash with water and ethanol and dry to obtain TiO 2 / ZIF-8 core-shell structure nanocomposites.

[0042] Figure 6 It is the SEM figure of the product of Example 2 of the present invent...

Embodiment 3

[0044] (1) Add 5.45g tetrabutyl titanate to 20L ethylene glycol solution, stir evenly at room temperature for 12 hours, then add it to anhydrous acetone, stir rapidly for 30 minutes and then let stand for 2 hours; centrifuge the white suspension, water and ethanol washing and drying to obtain uniform TiO 2 Amorphous nanospheres; then these powders were added to 25% tetramethylammonium hydroxide aqueous solution, reacted at 180°C for 12h, and finally centrifuged, washed with water and ethanol and dried to obtain TiO 2 nanospheres.

[0045] (2) The prepared TiO 2 0.1 g of pellets was added to 40 mL of Zn(NO 3 ) 2 ·6H 2 Stir in O methanol solution for 1 h, then add 40 mL of 2-methylimidazole methanol solution with a molar concentration of 1.2 mol / L, continue stirring for 2 h, centrifuge, wash with water and ethanol and dry to obtain TiO 2 / ZIF-8 core-shell structure nanocomposites.

[0046] Figure 7 It is the SEM figure of the product of Example 3 of the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com