A method for prepare a nitrogen doped carbon nanotube three-dimensional composite material by in-situ growth of a small lay of titanium carbide

A nitrogen-doped carbon, in-situ growth technology, used in electrical components, battery electrodes, circuits, etc., can solve the problems of high price and lack of firmness of CNTs, and achieve the effect of improving transmission capacity, improving conductivity and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

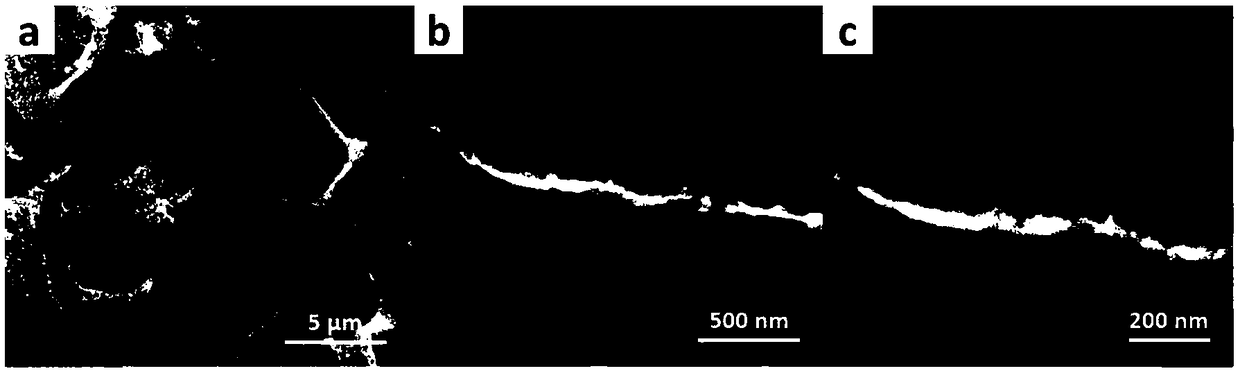

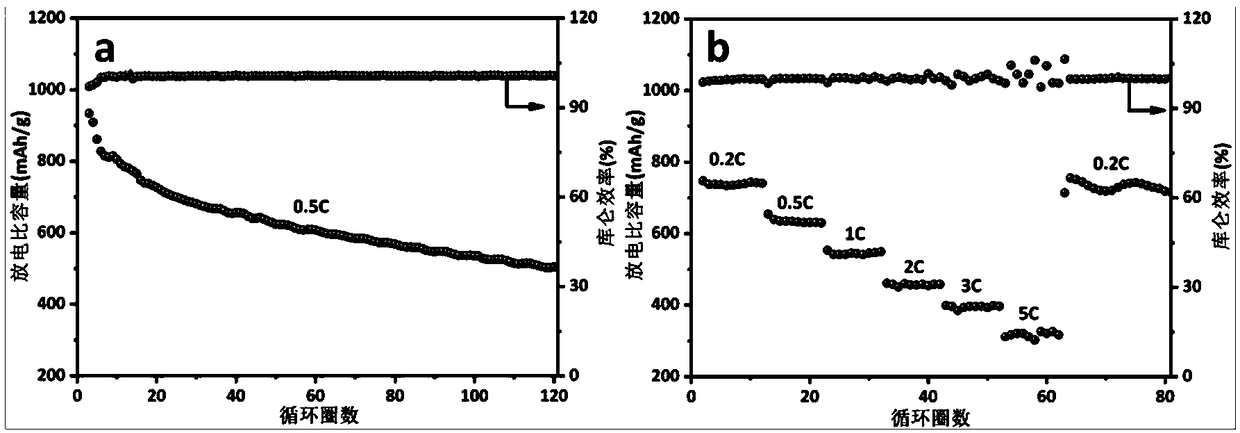

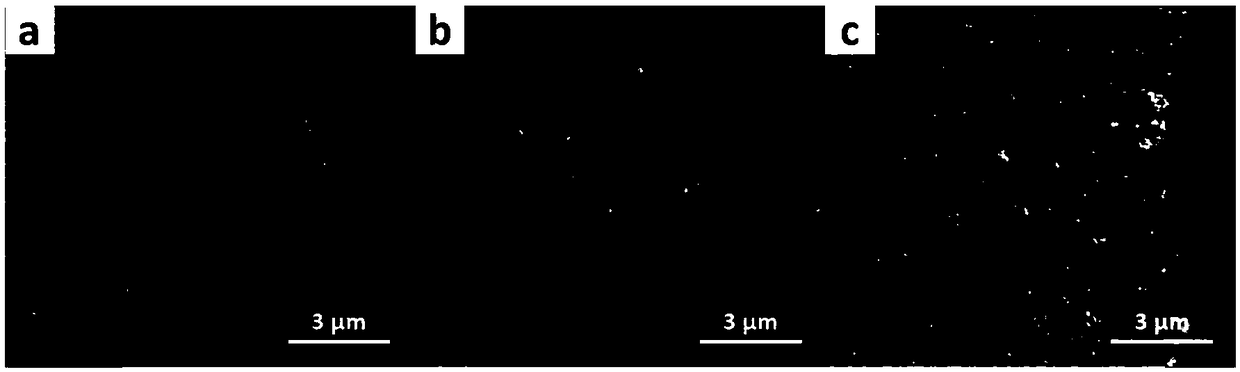

[0038] First, the 3 g ternary layered Ti 3 AlC 2 The ceramic powder is slowly immersed in 50 mL of hydrofluoric acid solution (40 wt.%) and magnetically stirred at 50°C for 72 h at a speed of 500 r / min, and then the corrosion products are centrifuged, 8000 r / min with absolute ethanol After centrifugation and cleaning until the pH of the supernatant is 6, the resulting precipitate is dried in a vacuum drying oven at 60°C for 24 hours to obtain a two-dimensional layered titanium carbide nanopowder. Then, 0.2 g of titanium carbide nanopowder was added to 10 mL of tetramethylammonium hydroxide solution (25wt.%), heated and stirred at 30 ℃ for 24 h, then centrifuged, and then centrifuged with deionized water to obtain a few layers of titanium carbide Nanosheet dispersion, the dispersion concentration is about 1 mg / mL. Take 125 mL of small-layer titanium carbide nanosheet dispersion, add 0.25 g of cobalt acetate tetrahydrate, and ultrasonically disperse for 30 min with an ultrasonic ...

Embodiment 2

[0041] First, the 3 g ternary layered Ti 3 AlC 2 The ceramic powder is slowly immersed in 50 mL of hydrofluoric acid solution (40 wt.%), magnetically stirred at 50°C for 72 h at a speed of 500 r / min, and then the corrosion products are centrifuged, 8000 r / min with ultrapure The supernatant was washed by centrifugation with water until the pH of the supernatant was 6, and then washed with absolute ethanol for 5 times. The resulting precipitate was dried in a vacuum drying oven at 60°C for 24 h to obtain a two-dimensional layered titanium carbide nanopowder. Then, 0.2 g of titanium carbide nanopowder was added to 10 mL of tetramethylammonium hydroxide solution (25 wt.%), heated and stirred at 30 ℃ for 24 h, and then centrifuged, and then centrifuged with deionized water to obtain less layer carbonization Titanium nanosheet dispersion, the dispersion concentration is about 1 mg / mL. Take 100 mL of the dispersion of titanium carbide nanosheets with few layers and add 0.2 g C 4 H 6 C...

Embodiment 3

[0043] First, add 3 g of ternary layered Ti 3 AlC 2 The ceramic powder is slowly immersed in 50 mL of hydrofluoric acid solution (40 wt.%), magnetically stirred at 50°C for 72 h at a speed of 500 r / min, and then the corrosion products are centrifuged, 8000 r / min with ultrapure The supernatant was washed by centrifugation with water until the pH of the supernatant was 6, and then washed with absolute ethanol for 5 times. The resulting precipitate was dried in a vacuum drying oven at 60°C for 24 h to obtain a two-dimensional layered titanium carbide nanopowder. Then, 0.2 g of titanium carbide nanopowder was added to 5 mL of tetramethylammonium hydroxide solution (25 wt.%), heated and stirred at 30 ℃ for 24 h, and then centrifuged, and then centrifuged with deionized water to obtain less layer carbonization Titanium nanosheet dispersion, the dispersion concentration is about 1 mg / mL. Take 200 mL of small-layer titanium carbide nanosheet dispersion, add 0.4 g of cobalt chloride he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com