Method for preparing modified asphalt mixture using waste and old tyre and hybrid method

A technology of waste tires and modified asphalt, which is used in building thermal insulation materials, on-site coagulation pavement, building components, etc., to achieve environmental protection engineering benefits, reduce road traffic noise, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

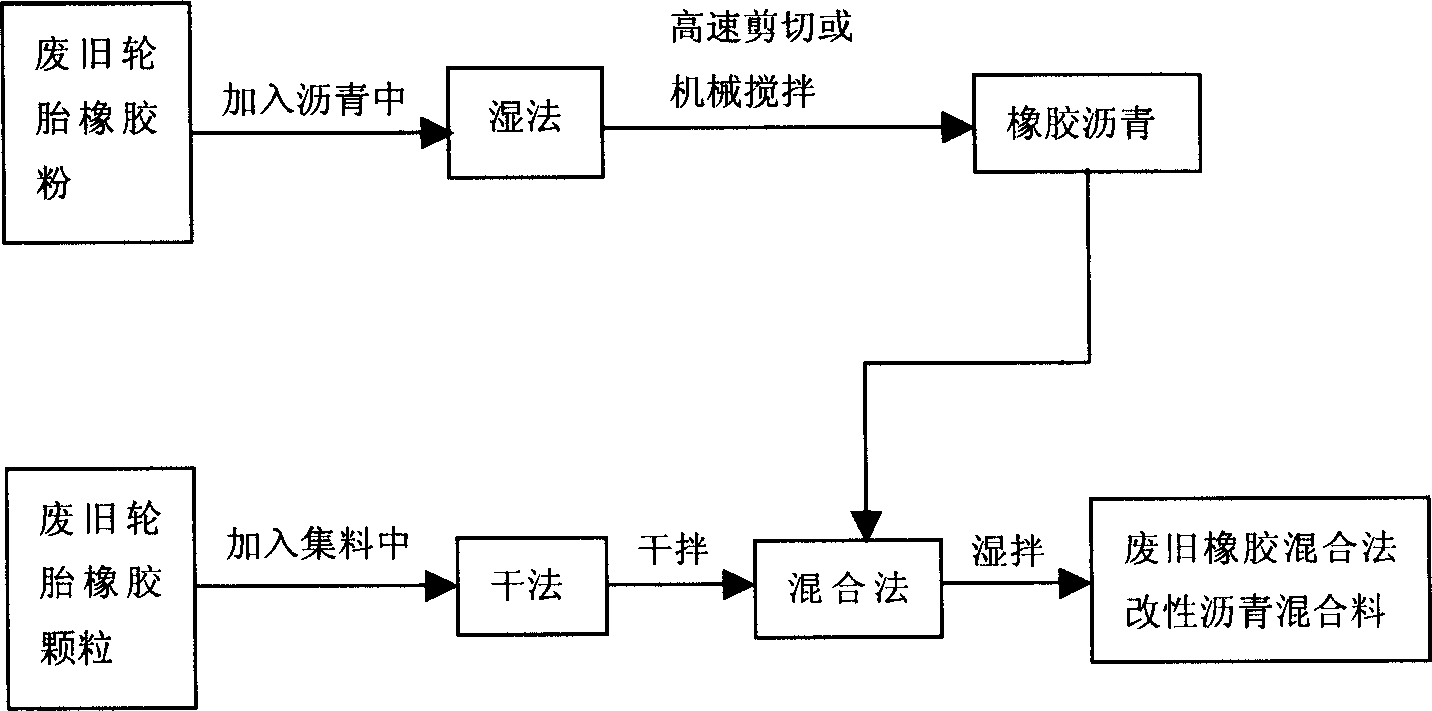

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of rubber-modified asphalt mixture at the construction site

[0035] (1) Preparation of rubber asphalt

[0036] The base asphalt is AH-70 asphalt, and its technical indicators are shown in Table 1. The fine rubber powder is crushed and ground from waste tires at room temperature to obtain 80-mesh fine rubber powder with a relative density of 1.15.

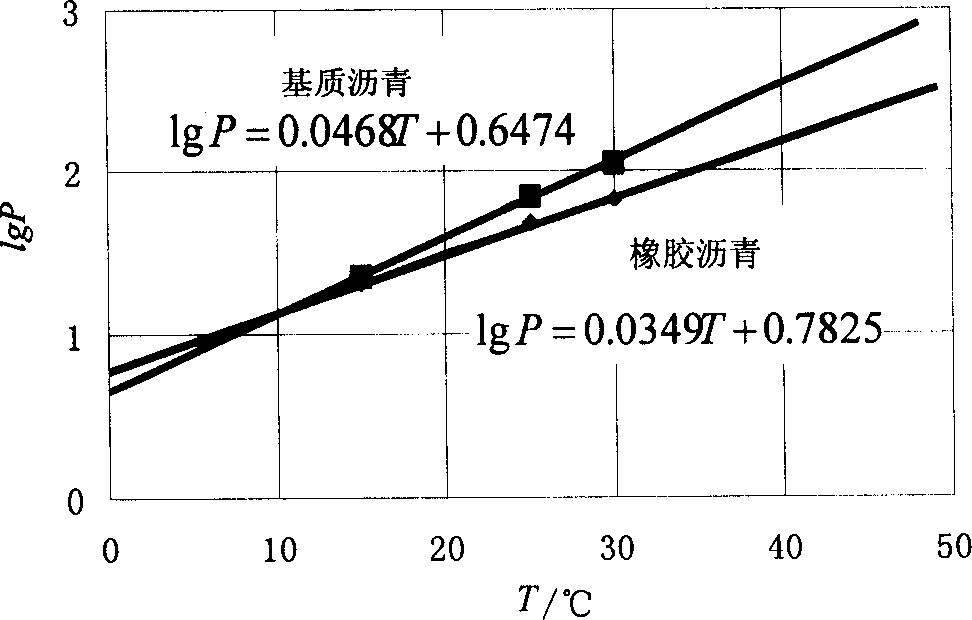

[0037] indicators

[0038] The AH-70 asphalt is heated to 190°C, the amount of fine rubber powder is determined to be 15% of the mass of the base asphalt, and the mixing temperature is controlled at 190°C-195°C. Use a high-speed shearing device to mix for 15 minutes, and the stirring speed is 1500 rpm, so that the fine rubber powder is evenly dispersed in the base asphalt, and then continue to stir for 45 minutes, so that the fine rubber powder and the base asphalt can fully react at high temperature, reaching Desired binder properties. Table 2 is the performance index test results of 80 m...

Embodiment 2

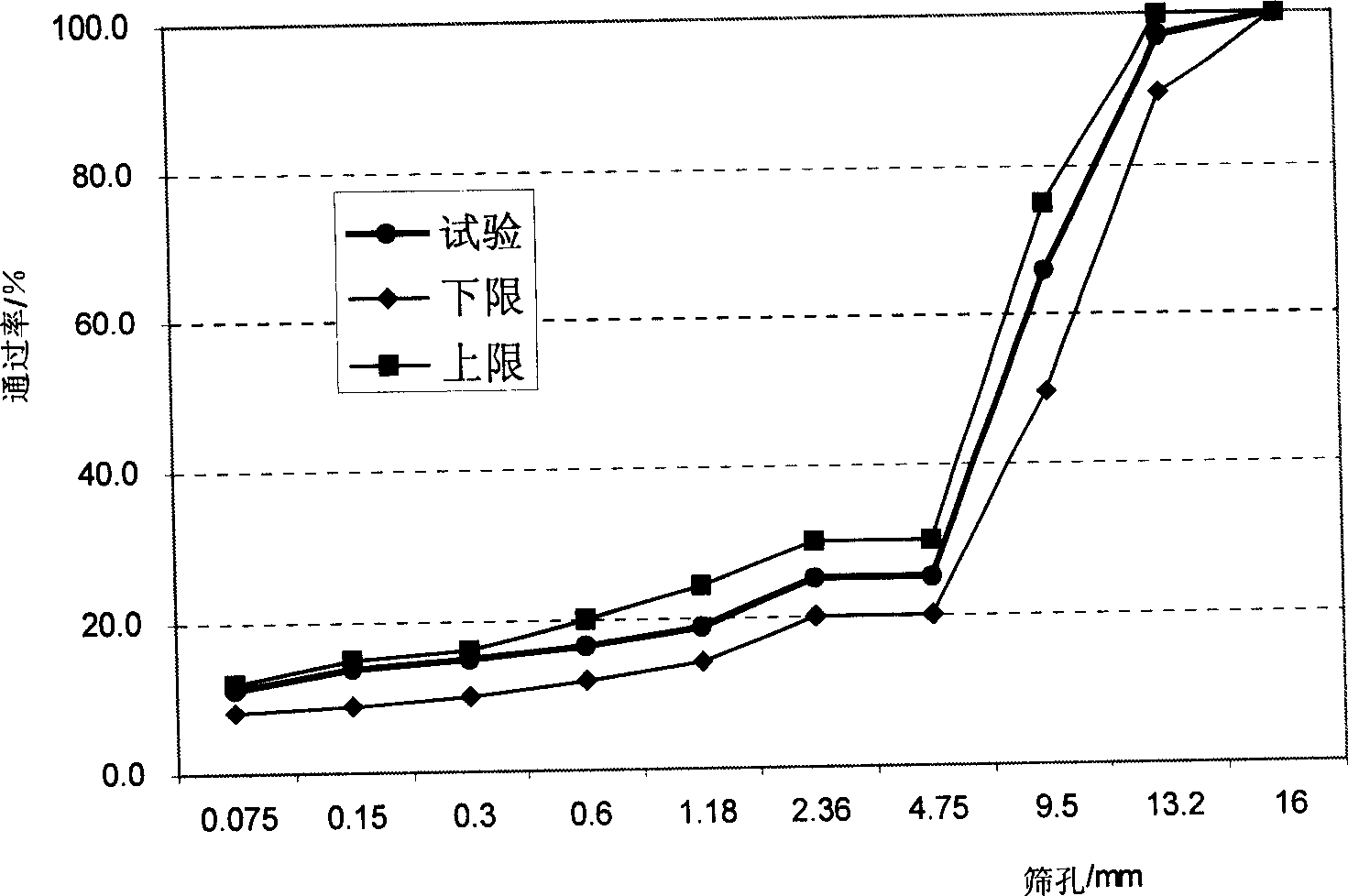

[0052] Example 2: Preparation of rubber-modified asphalt mixture in the laboratory

[0053] The coarse aggregate that adopts in the present embodiment is basalt, and the Vita linking agent of 5% (the mass number of rubber powder) is mixed in the preparation process of rubber asphalt, all the other raw materials are identical with embodiment 1, and the adding of Vita linking agent promotes The rubber powder is chemically combined with the bitumen to reduce the precipitation of the rubber powder.

[0054] (1) Preparation of rubber asphalt

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com