Door and window sill gasket

a technology for sealing gaskets and doors, applied in the direction of joints, tightening/covering, construction, etc., can solve the problems of large damage to exterior and interior surfaces, most common failure points of unwanted air and/or moisture in the building envelope, and the extent of such damage has run into millions of dollars annually, so as to reduce the effect of monthly utility costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

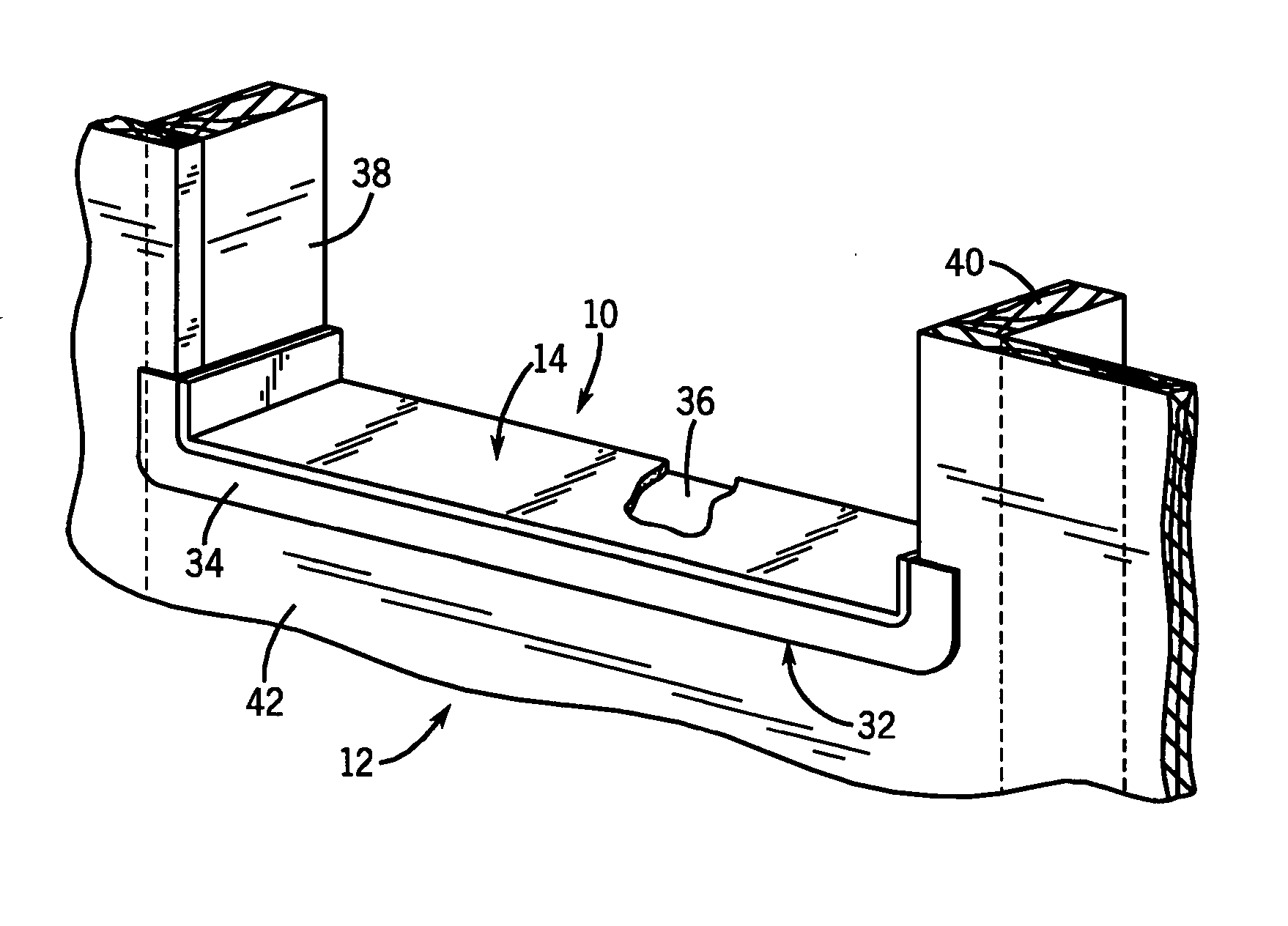

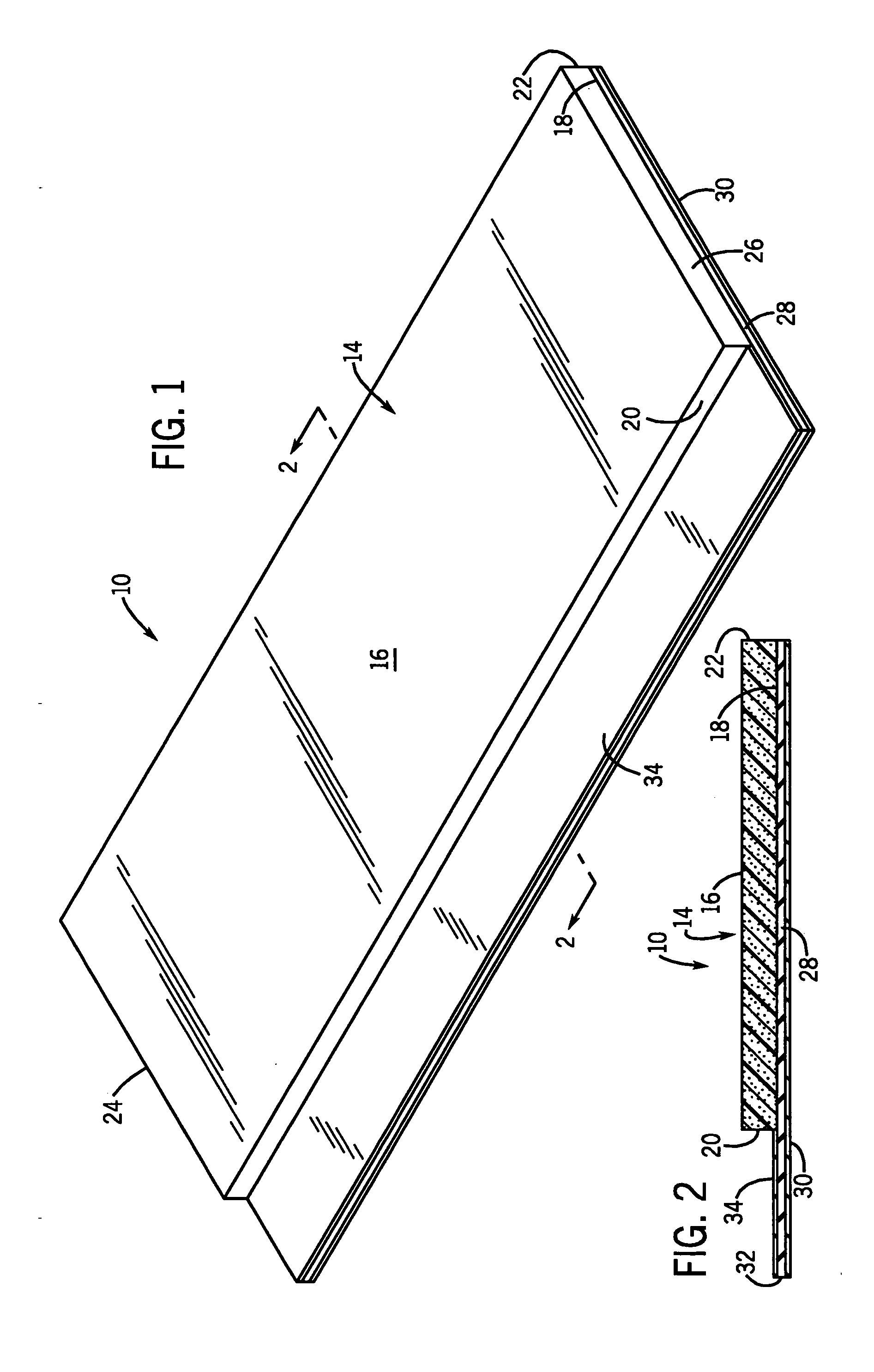

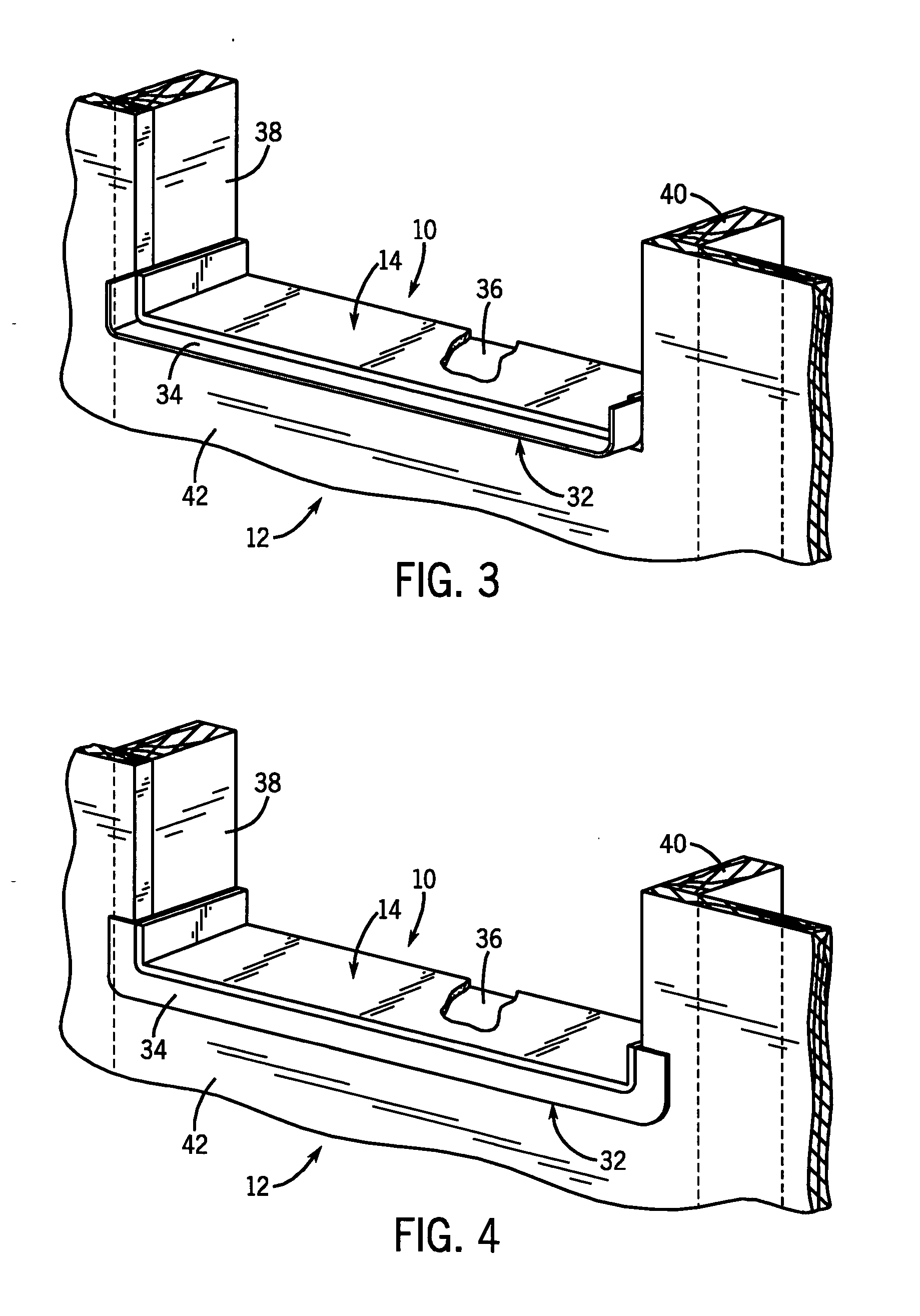

[0038] Referring now the drawings, FIGS. 1-5 illustrate a sill gasket 10 for sealing a door frame 12 against moisture, air and insect infiltration.

[0039] As seen in FIGS. 1 and 2, the sill gasket 10 includes a layer of a water resistant, compressible material 14 preferably constructed of closed cell polyethylene foam or similar material such as rubber or the like, having an upper surface 16, a lower surface 18, a front edge 20, a rear edge 22 and a pair of opposed side edges 24, 26. The lower surface 18 of the material 14 is attached to an adhesively-coated top face of a peel and stick rubberized, waterproof, modified asphalt sealing membrane 28 for providing an air / water / insect infiltration barrier. The membrane 28 has an adhesively-coated lower face covered by a peel away release liner 30, typically made of paper. The membrane 28 includes a flexible, covered gasket flange 32 which extends outwardly from the front edge 20 of the material 14. Preferably, a silicon release liner 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com