Rubber bituminous mixture partially using slag as coarse aggregate

A technology for rubberized asphalt and coarse aggregates, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of inconvenient normal road traffic, poor resistance to vehicle impact, increased use costs, etc., to improve The effect of long-term road performance, alleviating supply pressure and reducing project cost

Inactive Publication Date: 2011-01-19

上海佳砼新材料科技发展有限公司

View PDF7 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These pavement materials mixed with steel slag have the advantages of low cost, environmental protection and saving, but the surface porosity of steel slag material is large, but its brittleness is relatively poor, and its ability to resist vehicle impact is poor, and the durability of use is difficult to meet the requirements.

Therefore, frequent maintenance is required, which not only increases the cost of use, but also brings inconvenience to the normal passage of the road.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

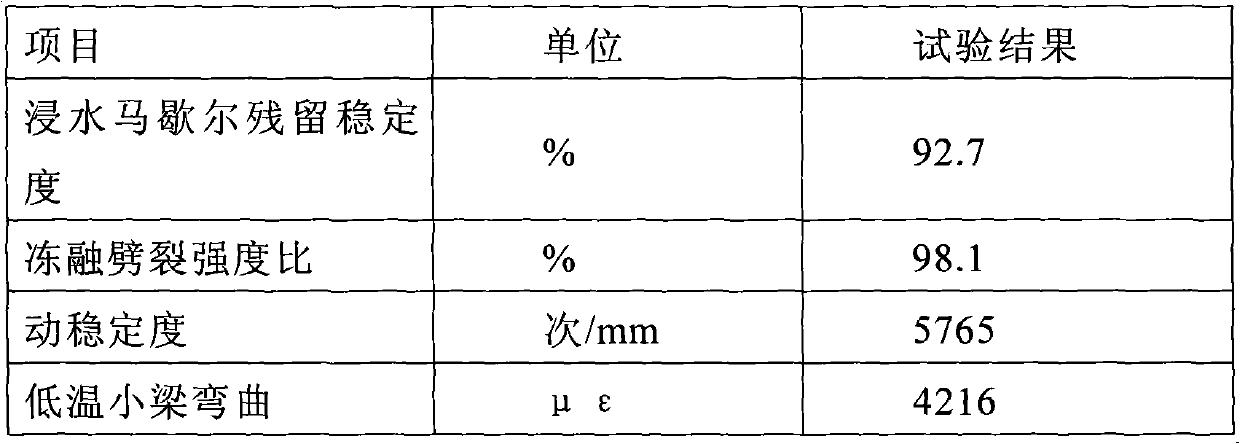

The invention belongs to the technical field of building materials used in road engineering, particularly relating to a high-strength wear-resisting rubber bituminous mixture partially using slag as coarse aggregate. The mixture comprises slag coarse aggregate, natural stone coarse aggregate, fine aggregate, filler and rubber asphalt, wherein part of coarse aggregate is the slag; part of coarse aggregate is basalt, diabase or limestone; the fine aggregate is limestone, diabase or basalt; the filler is cement or a mixture of limestone mineral powder and slaked lime; and the rubber asphalt is produced by selecting waste cart tire rubber powder with a granularity greater than or equal to 20 meshes and lower than or equal to 40 meshes. The invention fully utilizes the slag, waste tires and other waste materials and turns waste into wealth, thereby effectively relieving environmental pollution caused by the slag and the waste tires. The mixture is a dense grade bituminous mixture using the slag as the coarse aggregate and using the rubber asphalt as a matrix, which has good high-temperature stability, low-temperature crack resistance, normal-temperature fatigue resistance and other performances, and is applicable to various traffic road engineering.

Description

technical field [0001] The invention belongs to the technical field of building materials used in road engineering, and in particular relates to a high-strength wear-resistant rubber asphalt mixture partially using steel slag as coarse aggregate. Background technique [0002] my country is a big country of steel production. Its steel output has been ranked first in the world for many years, and it is shaking ahead of other countries. Steel slag is the main industrial solid waste produced along with the steelmaking process. The discharge of steel slag is nearly 60 million tons per year. The cumulative stacking capacity is nearly 200 million tons. The stacking of steel slag occupies valuable urban land and causes a lot of waste of resources. In addition, due to the free calcium oxide contained in the steel slag, the calcium oxide dissolves in the water after a large amount of rainwater washes away, causing the nearby soil to become alkaline, and the pH value of the nearby wate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B26/26C04B18/14

CPCC04B28/02C04B26/26C04B28/12C04B18/142Y02W30/91C04B7/00C04B14/02C04B18/22C04B20/0076C04B20/0092C04B14/28C04B22/064C04B14/14C04B20/0096C04B24/36

Inventor 钱卫胜王莉毛安吉张湧许东良刘艳滨孙文州谢兆星罗建晖周亚军魏沫夏珊珊张朝晖李达辉印冬明

Owner 上海佳砼新材料科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com