Porous pavement partially taking steel slag as coarse aggregate

A technology of permeable pavement and coarse aggregate, which is applied to the coagulation pavement, roads, roads and other directions paved on site to achieve the effect of improving long-term road performance, reducing project cost and easing supply pressure.

Active Publication Date: 2012-11-14

上海砼仁环保技术发展有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to solve the urban traffic and environmental problems caused by the impermeable road surface to the greatest extent, the present invention treats and utilizes steel slag and waste tires at the same time, and reduces the demand for natural resources in road engineering construction, and proposes a water-permeable road that partially uses steel slag as coarse aggregate. pavement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

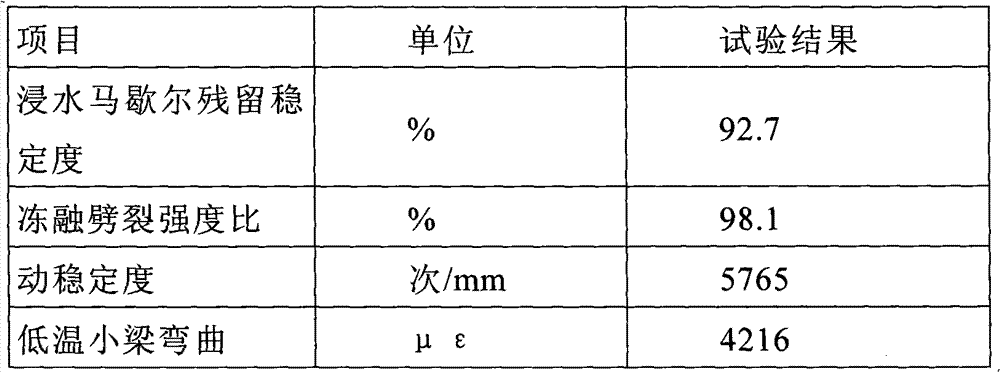

The invention belongs to the technical field of porous pavements and particularly relates to a porous pavement partially taking steel slag as a coarse aggregate and taking rubber asphalt as an adhesive. In the porous pavement partially taking the steel slag as the coarse aggregate, the thickness of a structural layer of the porous pavement is between 2.0 and 4.0 centimeters; and the maximum nominal particle size of a construction mixture is 9.5 millimeters. The porous pavement consists of the coarse aggregate, a fine aggregate and a filler, wherein the coarse aggregate is the mixture of the steel slag coarse aggregate and a natural stone coarse aggregate; the fine aggregate is a limestone, diabase or basalt aggregate; and the filler is cement or the mixture of limestone mineral powder andslaked lime. The used rubber asphalt is produced from waste large tire rubber powder of which the particle size is more than or equal to 20 meshes and smaller than or equal to 40 meshes. Traffic and environmental problems caused by a nonporous pavement are solved to the greatest extent, the long-term pavement performance of an asphalt pavement is improved by using the steel slag and waste tires, the supply pressure of a high-quality aggregate is relieved and engineering cost is lowered.

Description

technical field [0001] The invention belongs to the technical field of permeable pavement, in particular to a permeable pavement partially using steel slag as coarse aggregate and rubber asphalt as binder. Background technique [0002] If you want to get rich, build roads first. With the rapid development of my country's economy, cities have built a large number of roads. However, urban roads mostly adopt impermeable hardened pavement. These impermeable pavements have brought many traffic and environmental problems to the city. For example, the hardened road surface reduces the air exchange and air humidity on the ground, accelerates the urban heat island effect, increases the average temperature of the ground, and increases energy consumption. In addition, impermeable roads are prone to water accumulation in rainy days, which not only affects the passage of people and vehicles, but also increases the safety hazards of urban traffic. [0003] Based on the various drawback...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B26/26E01C7/10

CPCC04B28/02C04B28/12C04B26/26C04B18/142Y02W30/91C04B7/00C04B14/02C04B18/22C04B20/0076C04B20/0096C04B14/28C04B22/064C04B14/14C04B24/36

Inventor 钱卫胜周亚军

Owner 上海砼仁环保技术发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com