Semi-flexible pavement material, preparation method therefor and semi-flexible pavement

A semi-flexible pavement and raw material technology, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of poor surface and interface bonding performance, large dry shrinkage and temperature shrinkage of grouting materials, and large temperature sensitivity differences. , to achieve the effect of improving crack resistance, crack resistance and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of semi-flexible pavement material of the present invention may further comprise the steps:

[0049] The mixture contains 15-20 parts by mass of cement, 8-10 parts of emulsified asphalt, 0.03-0.06 parts of water reducer, 0.06-0.2 parts of polypropylene fiber, 10-15 parts of mineral powder, 30-35 parts of sand, 8-10 part of fly ash, 0.06 to 0.12 part of expansion agent and 0.03 to 0.06 part of interface modifier to obtain cement slurry;

[0050] and supply of asphalt mixture.

[0051] The above-mentioned mixing method to obtain the cement slurry can be mechanical stirring. The rotating speed of mechanical stirring can adopt low speed stirring, such as 50~150rpm. Under the rotating speed of the mechanical stirring, the time of the mechanical stirring can be 20-40s, such as 20s, 25s, 30s, 35s or 40s.

[0052] As for the order of mixing to obtain the cement slurry, it can be better specifically: first add water, emulsified asphalt and cement to the...

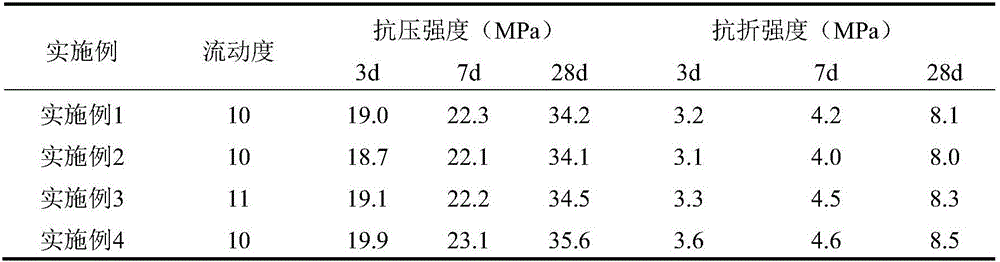

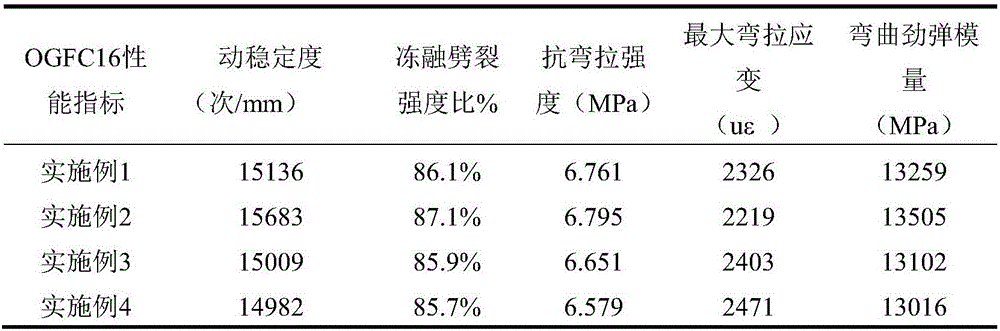

Embodiment 1

[0057] Step 1, proportioning raw materials. The raw materials include 30wt% cement grouting material and 70wt% asphalt mixture, calculated as 100wt% of the total mass of the raw materials. Among them, the cement grouting material contains 20 parts of PO42.5 Portland cement, 9 parts of SBR emulsified asphalt, 0.06 parts of polycarboxylate water reducer, 0.085 parts of polypropylene fiber, 12 parts of mineral powder, 35 parts of sand, 5 parts by mass. Parts of fly ash, 0.09 parts of expansion agent, 0.03 parts of interface modifier and 13 parts of water.

[0058] Step 2, preparing cement grouting material. Specifically, put water, SBR emulsified asphalt, and cement into the mixing pot at one time and mix them. After stirring at a low speed for 30 seconds, fly ash, polypropylene fiber, mineral powder, water reducing agent, expansion agent, and interface modifier are put into the mixer in turn. The grouting material is mixed with a high-speed mixer to obtain a cement grouting ma...

Embodiment 2

[0062] Step 1, proportioning raw materials. The raw materials include 15wt% cement grouting material and 85wt% asphalt mixture, calculated as 100wt% of the total mass of the raw materials. Among them, the cement grouting material contains 15 parts of PO42.5 Portland cement, 10 parts of SBR emulsified asphalt, 0.03 parts of polycarboxylate water reducer, 0.2 parts of polypropylene fiber, 10 parts of mineral powder, 30 parts of sand, 8 parts by mass. Part fly ash, 0.06 part expansion agent, 0.03 part interface modifier and 10 parts water.

[0063] Step 2, preparing cement grouting material. Specifically, put water, SBR emulsified asphalt, and cement into the mixing pot at one time and mix them. After stirring at a low speed for 20 to 40 seconds, fly ash, polypropylene fiber, mineral powder, water reducing agent, expansion agent, and interface modifier are added in sequence. Mixer, the grouting material is mixed with a high-speed mixer to obtain the cement grouting material.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com