Asphalt rubber waterproof coating material

A waterproof coating and asphalt technology, applied in asphalt coatings, natural rubber coatings, coatings, etc., can solve the problems of poor durability of rubber asphalt waterproof coatings, achieve good impermeability and mechanical properties, ensure compatibility and construction Performance, non-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

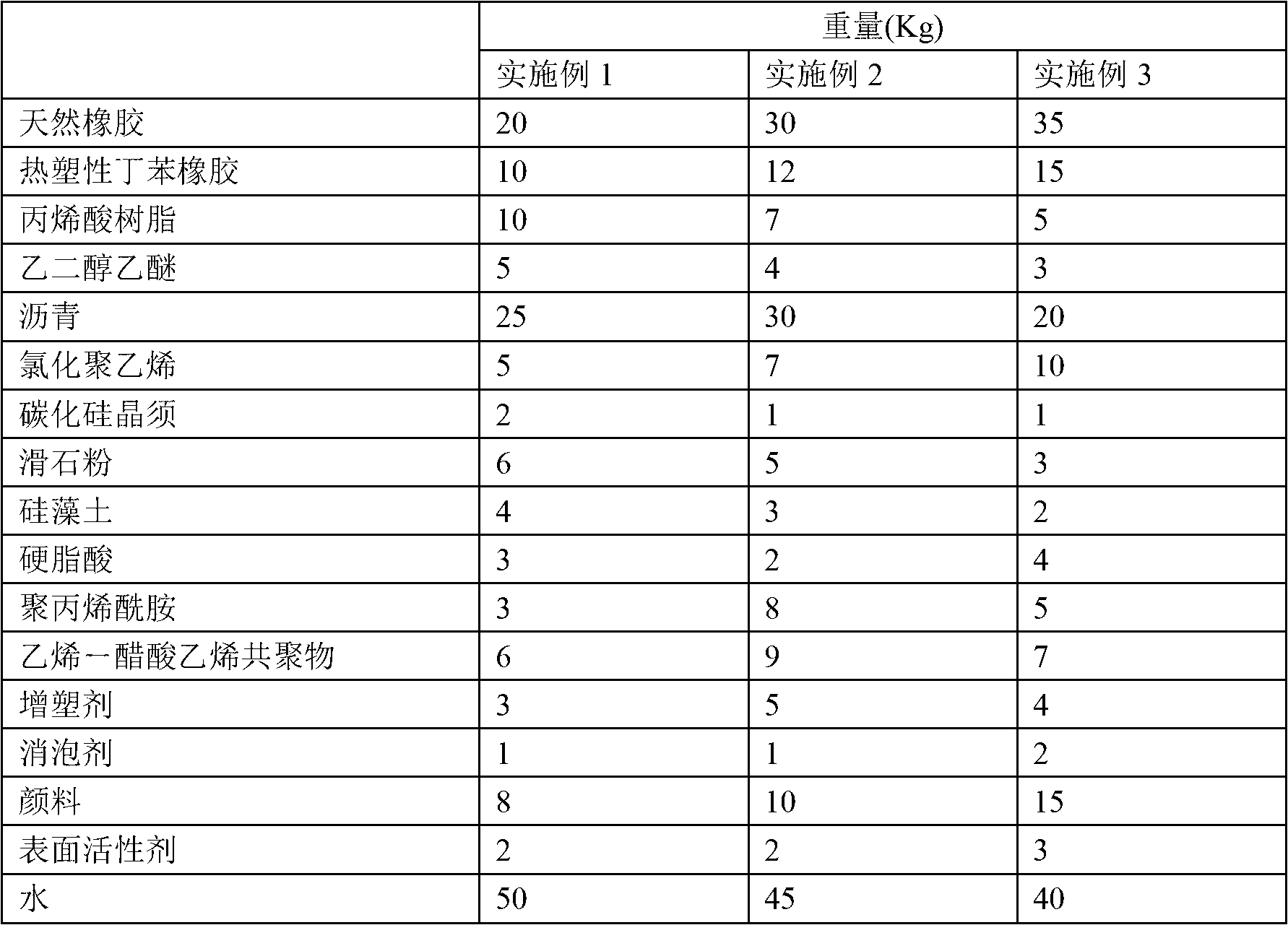

Examples

Embodiment 1

[0030] S1: After plasticizing natural rubber and thermoplastic styrene-butadiene rubber at 70-80°C, add half the weight of surfactant, and mix evenly;

[0031] S2: Enter the shearing machine after unloading, and perform rotary shearing at 500 rpm at 70°C;

[0032] S3: Add half of the weight of surfactant and half of the weight of water to the product obtained in S2, shear for 30 minutes, and then cut at 800 rpm for 5 minutes to obtain a rubber emulsion;

[0033] S4: Heating the asphalt to 140°C, keeping it warm, stirring evenly, then adding the remaining surfactant and water, stirring evenly to obtain an asphalt emulsion;

[0034] S5: Mix rubber emulsion, asphalt emulsion with acrylic resin, ethylene glycol ether, chlorinated polyethylene, silicon carbide whiskers, talcum powder, diatomaceous earth, stearic acid, polyacrylamide, ethylene-vinyl acetate copolymer, Mix plasticizer, defoamer, and pigment, stir evenly at 40°C, let cool, and get ready.

Embodiment 2

[0036] The difference with Example 1 is: the temperature in step S1 is 75°C; the temperature in step S2 is 75°C, and the rotating speed is 550rpm; in step S3, the rotating speed is 850rpm; the temperature in step S4 is 150°C; the temperature in step S5 is 45°C.

Embodiment 3

[0038] The difference with Example 1 is: the temperature in step S1 is 80°C; the temperature in step S2 is 80°C, and the rotating speed is 600rpm; in step S3, the rotating speed is 900rpm; the temperature in step S4 is 160°C; the temperature in step S5 is 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com