Rubberized asphalt pellets

A technology of asphalt granules and granules, applied in coatings, building components, building insulation materials, etc., can solve the problems of lengthy and expensive preparation of asphalt pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

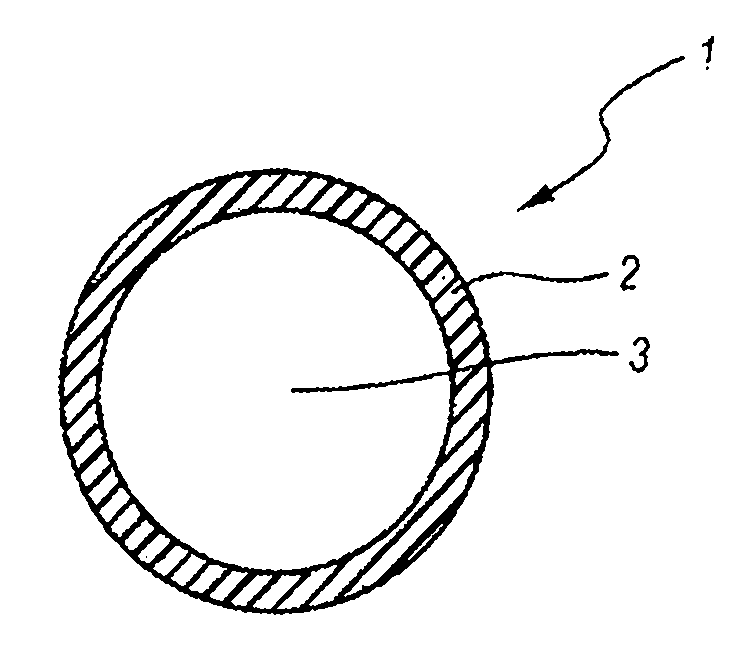

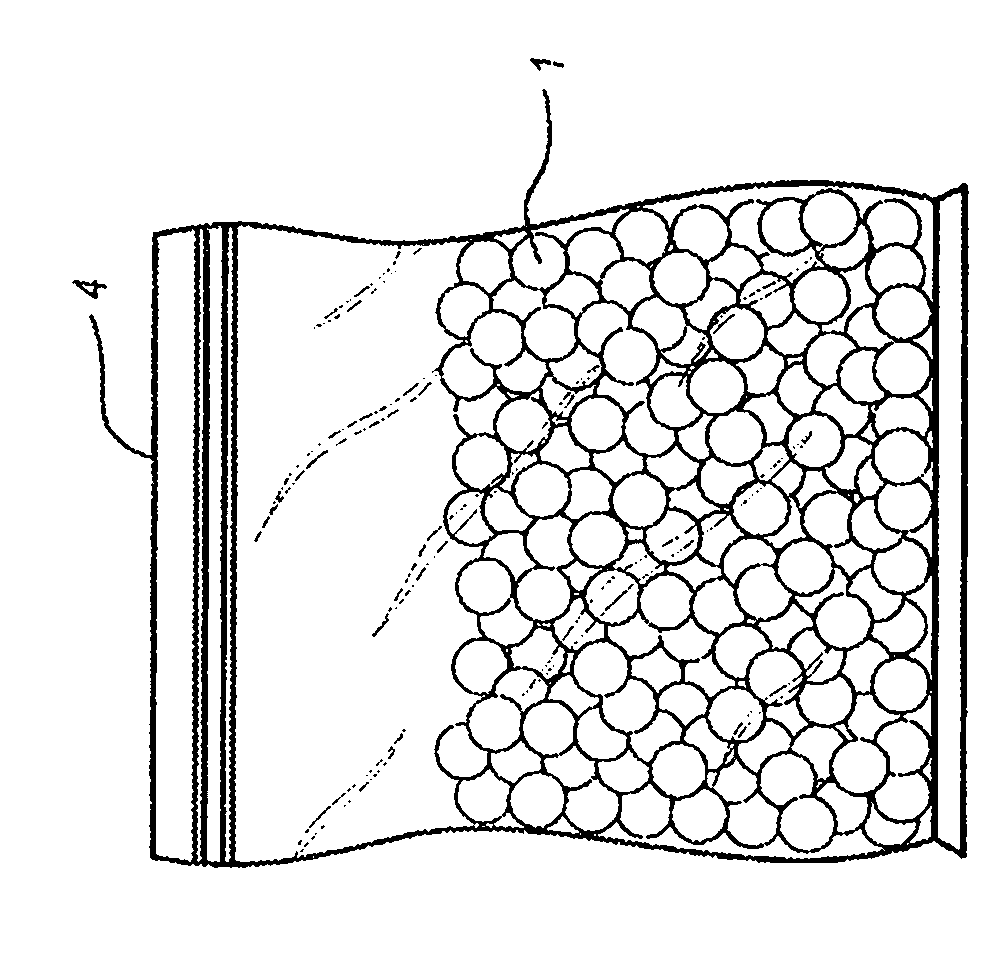

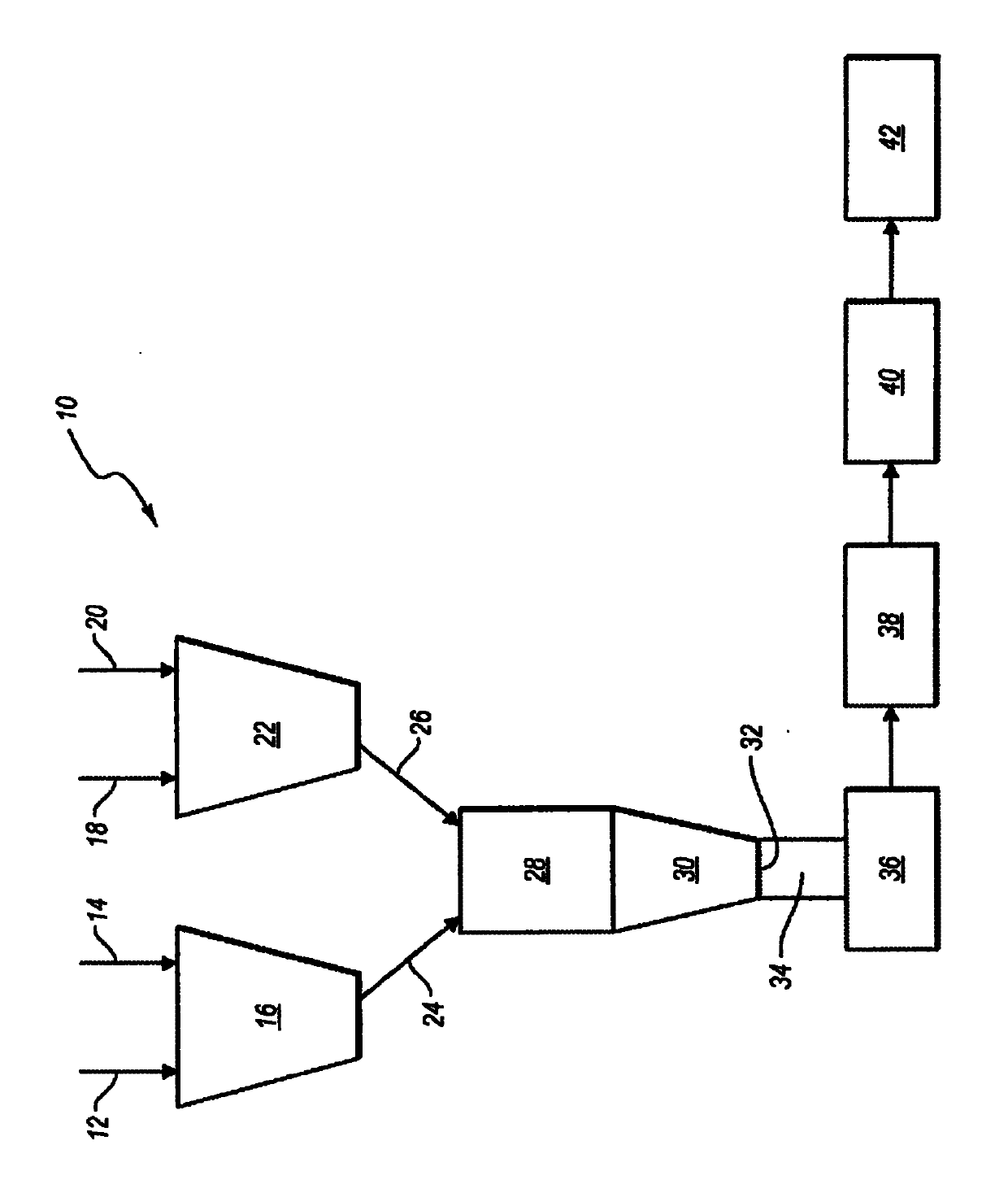

[0064] The method of producing rubberized asphalt pellets may include grinding waste rubber, such as scrap tire rubber, into fine particles for use in making asphalt pellets. The rubber particles of the present invention include emulsified rubber and / or rubber particles agglomerated with bitumen to form particles. Rubber is ground to a particle size that can range from fine aggregate size to smaller than particle size. The particles are preferably formed from a plurality of rubber particles. This includes at least 2 or more rubber particles, more preferably about 2 to 10 rubber particles, more preferably about 5 to about 50 rubber particles, most preferably about 10 to 100 or more rubber particles.

[0065] Tire rubber used in the manufacture of asphalt / rubber adhesives is available in a variety of sizes. However, it may be advantageous to grind the rubber to less than about 8 mesh, more preferably less than about 14 mesh, most preferably less than about 20 mesh.

[0066] c...

Embodiment 1

[0201] Nuclei for asphalt pellets were prepared using a pan pelletizer and related methods. Briefly, a supply of fine aggregate is added to the turntable of a pan pelletizer in an amount capable of forming granules. Then, the liquefied pavement-grade asphalt is dripped or sprayed onto the fine aggregate. Pellets are formed by repeated contact of droplets of bitumen with fine aggregate, which, when sufficiently sized, overflow the rim of the pelletizer. The average size of the particles is expected to be 0.62 cm.

[0202] Alternatively, the fines are poured into a falling curtain of fines and the binder is sprayed into the fines to create granules. Optionally, atomization and wax coating may be alternately performed to provide core-shell bitumen particles.

Embodiment 2

[0204] A series of particle cores with different compositions were prepared according to the protocol of Example 1 with minor modifications. Briefly, liquefied rubber asphalt-based binders of different compositions were added to fine aggregates. The feed rate of fine aggregate and / or binder is varied to vary the size and composition of the particles. The expected shape, size (average diameter) and composition of the particle cores are shown in Table 1 below:

[0205] Table 1

[0206]

[0207]

[0208]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com