Novel lightweight wall

A light-weight wall and a new type of technology, applied in the direction of walls, building components, insulation, etc., can solve the problems of wall cracks, unfavorable transportation, high cost, etc., to achieve improved wall flatness, obvious thermal insulation effect, and load-bearing direction consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

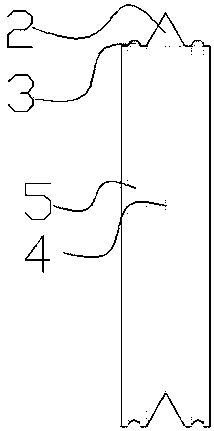

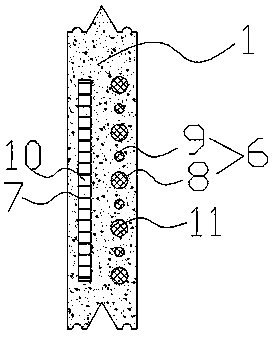

[0021] A new type of lightweight wall, comprising a wall 1 cast from foamed concrete, characterized in that the wall 1 is square, and a butt block and a butt groove are provided on the sides of the square, so that The number of the docking blocks is 2 groups, and the 2 groups of docking blocks are adjacently arranged, and the number of the docking grooves is 2 groups, and the 2 groups of docking grooves are adjacently arranged;

[0022] Each group of docking blocks is composed of 1 No. 1 docking block 2 and 2 No. 2 docking blocks 3. The No. 1 docking block 2 protrudes from the side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com