Prefabricated road process method with load monitoring module

A technology of monitoring module and process method, which is applied in the direction of roads, roads, and paving surfaces paved with prefabricated blocks, etc., can solve the problems of high subgrade quality requirements, cracking and breaking of prefabricated pavements, and uneven lifting, and achieve good grain shape and strength. Large, sturdy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

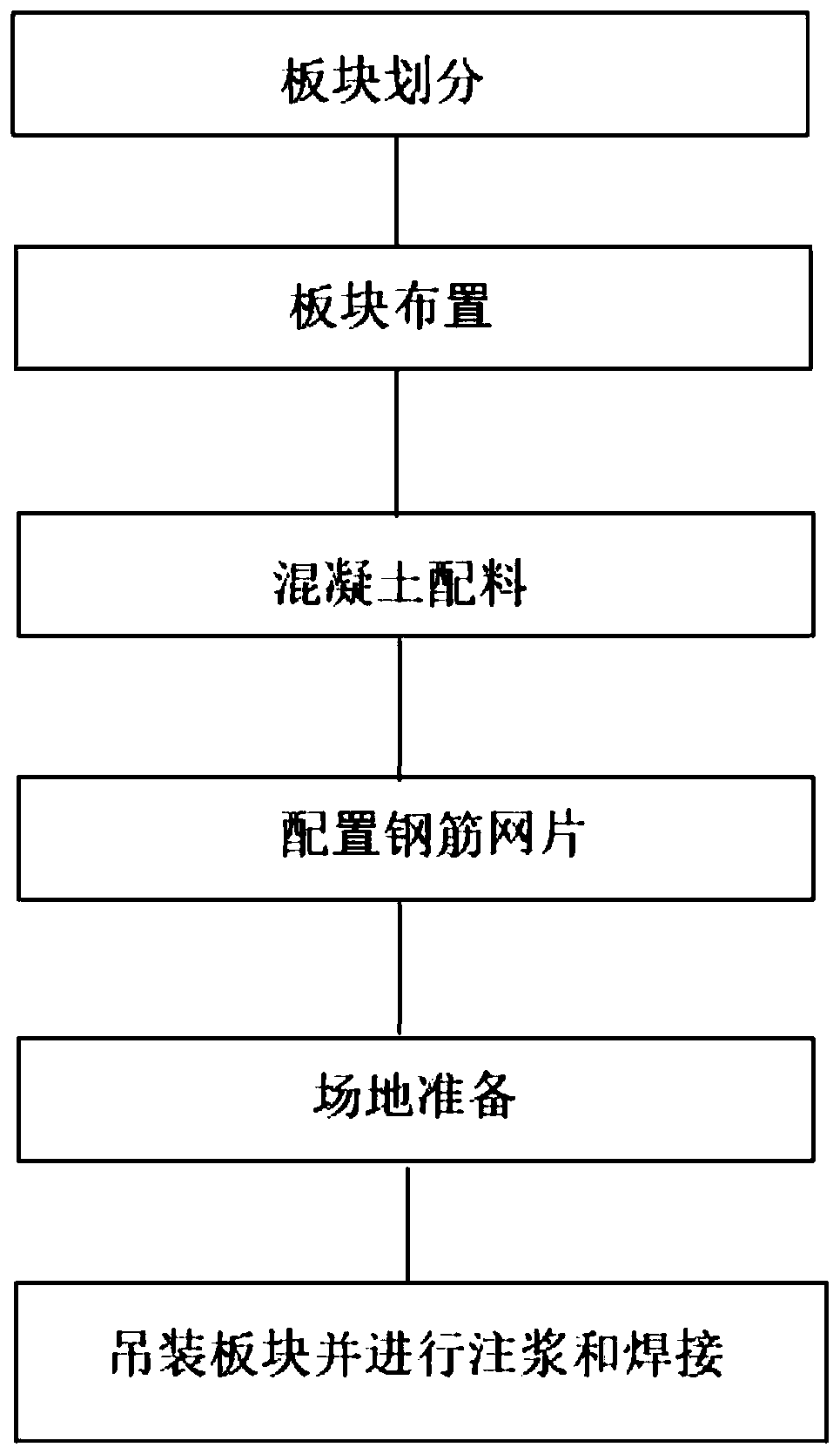

[0023] as attached figure 1 As shown, a prefabricated road technology construction method with a load monitoring module, the prefabricated road with a load monitoring module is suitable for roads with large passing traffic and heavy loads, and the prefabricated roads are divided into sections. The steps of the pavement construction method are divided into: plate division, plate layout, concrete batching, configuration of steel mesh, site preparation, hoisting plate and performing grouting and welding.

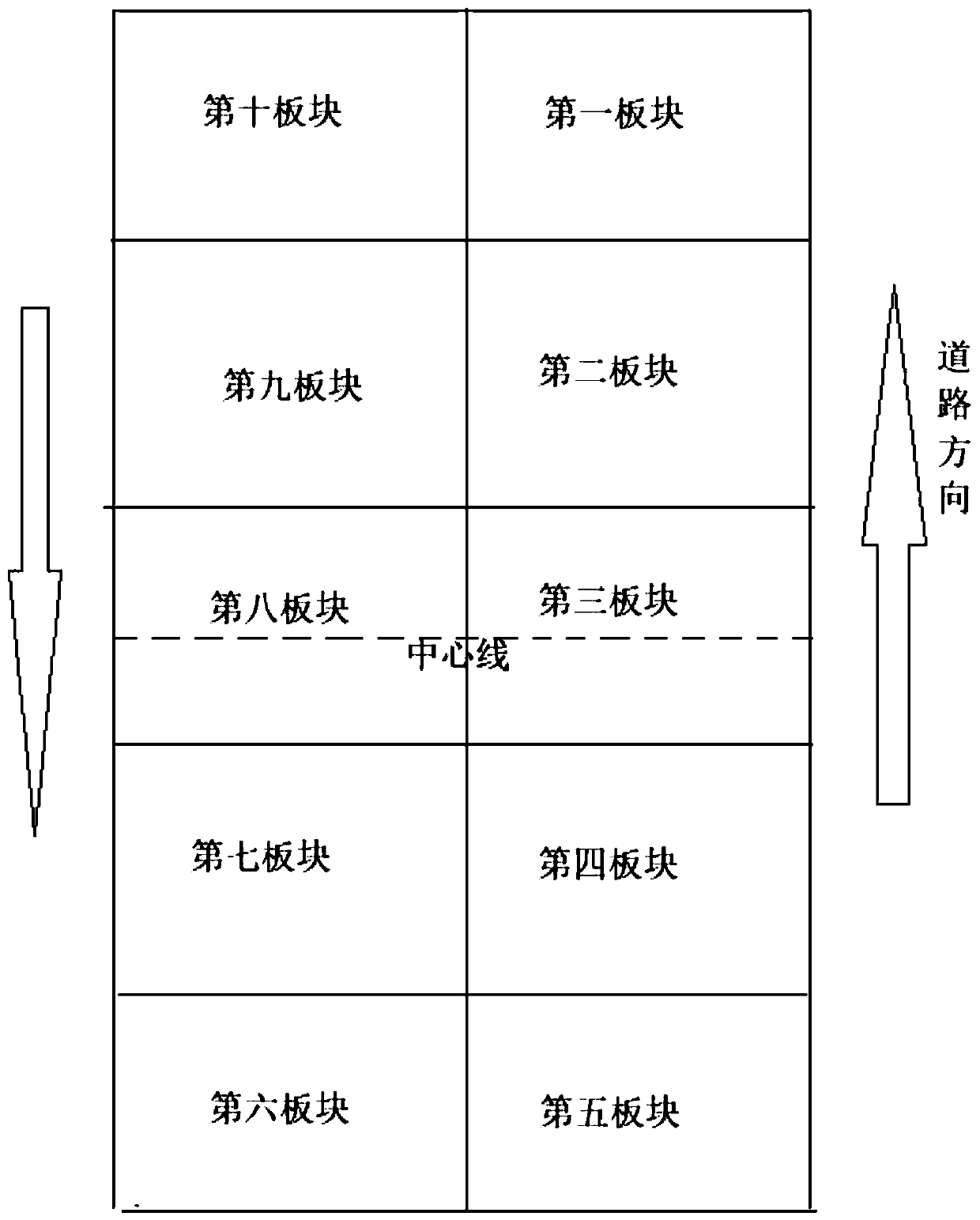

[0024] (1) Segment division: as attached figure 2 As shown, the plates are numbered, the prefabricated road is divided into ten plates, and the prefabricated road is divided into left and right sides. The plate numbers on the left side according to the direction of the road are: the tenth plate, the ninth plate, the eighth plate, the The seventh plate and the sixth plate; the plate numbers on the right according to the direction of the road are the fifth plate, the fourth pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com