Electric ink grinding machine using photovoltaic power generation as power supply

A photovoltaic power generation and power supply technology, which is applied to ink stations, printing, office supplies, etc., can solve the problems of unusable, time-consuming and laborious manual grinding of ink, damage to the integrity of the shell, etc., and achieve the effect of convenient charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

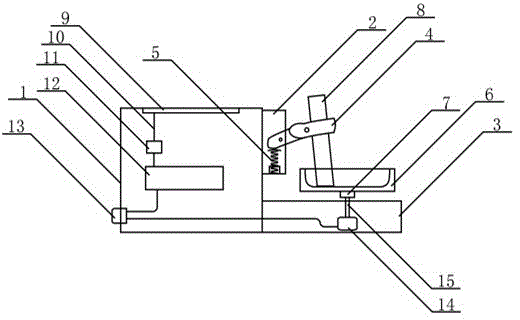

[0015] Monocrystalline silicon solar cells generate current under sunlight, and the current is adjusted through the conductive wire input controller, and then input into the energy storage battery for storage; the ink stick is clamped by the ink stick clamp, and under the action of the spring, the ink stick clings to the At the bottom of the inkstone pool of the inkstone; add an appropriate amount of water into the inkstone pool of the inkstone, press the switch, the circuit between the energy storage battery and the motor is connected, the motor starts to work, the power output shaft drives the inkstone to rotate through the connecting device, the ink stick and the inkstone The bottom of the inkstone pool begins to grind, and the ink-making raw materials in the ink stick begin to release and mix with the water in the inkstone pool to produce ink.

Embodiment 2

[0017] Polycrystalline silicon solar cells generate current under sunlight, and the current is adjusted through the conductive wire input controller, and then input into the energy storage battery for storage; the ink stick is clamped by the ink stick clamp, and under the action of the spring, the ink stick is tightly attached to the inkstone The bottom of the inkstone pool; add an appropriate amount of water to the inkstone pool, press the switch, the circuit between the energy storage battery and the motor is connected, the motor starts to work, the power output shaft drives the inkstone to rotate through the connecting device, the ink stick and the inkstone pool of the inkstone The bottom begins to grind, and the ink-making raw materials in the ink stick begin to release and mix with the water in the inkstone pool to produce ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com