Inkstone grinder

An ink-stone and ink-grinding technology, applied in ink-table, printing, office supplies, etc., can solve the problems of waste, difficulty, and inability to reuse ink sticks, and achieve adjustable ink grinding pressure and speed, controllable ink concentration, Avoid wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

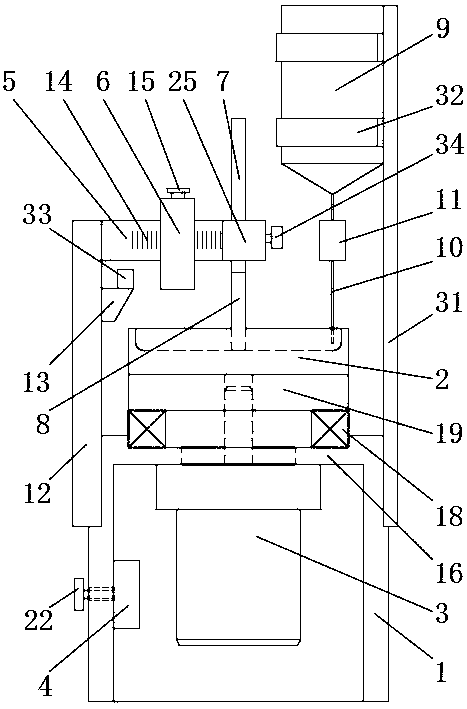

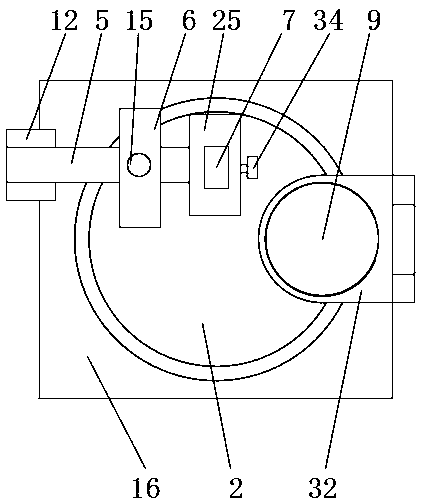

[0038] Such as figure 1 , 2, 4, 5, 6, and 8, the inkstone grinder includes an underframe 1 and an inkstone 2, a frequency modulation motor 3 and a frequency modulation controller 4 are fixedly installed in the underframe 1, and the frequency modulation controller 4 is connected with the frequency modulation motor 3 and The speed of the frequency modulation motor 3 can be adjusted. Specifically, the frequency modulation controller 4 is connected to the frequency modulation motor 3, and can control the frequency modulation motor 3 to change its operating frequency, thereby realizing the adjustment of the speed of the frequency modulation motor 3. The frequency modulation controller 4 is installed on the chassis 1 On the inner wall of the middle part, an adjustment indicator panel 21 is installed on the outer wall of the middle part of the chassis 1. The adjustment indicator panel 21 has an AC frequency adjustment indicator bar (not shown in the figure), and the adjustment rod 23...

Embodiment 2

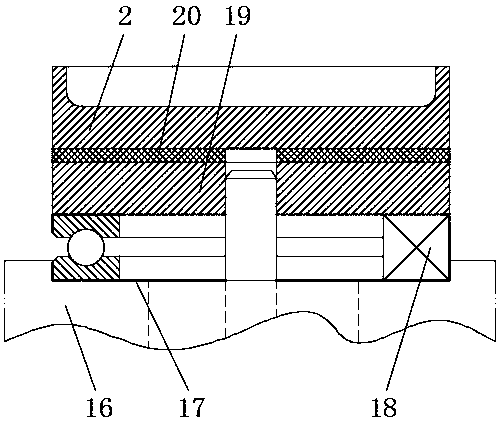

[0045] Such as figure 1 , 3 , 4, on the basis of embodiment 1, a top plate 16 is provided at the top of the underframe 1, and a through hole is provided on the top plate 16. A plane bearing 18 is fixedly installed in the groove 17. Specifically, the lower ring of the plane bearing 18 is fixedly installed in the installation groove 17. The upper ring does not contact the installation groove 17 and can rotate relative to the lower ring. The upper end surface of the plane bearing 18 is fixed. A horizontal grinding disc 19 is installed, and the grinding disc 19 is fixedly connected with the upper ring. The output shaft of the frequency modulation motor 3 passes through the through hole and the plane bearing 18 and is fixedly connected with the grinding disc 19. The inkstone 2 is arranged on the grinding disc 19. The frequency modulation motor 3 It can control the rotation of the grinding disc 19 relative to the base frame 1, and then control the rotation of the inkstone 2. This a...

Embodiment 3

[0048] Such as figure 1 , 2 , 7, 9 to 11, on the basis of embodiment 2, the ink stick assembly is detachably fixed and installed on the end of the crossbeam 5 through the chuck mechanism, and the end of the crossbeam 5 is provided with a threaded hole 24, specifically here Three threaded holes 24 are provided, and the chuck mechanism includes a chuck body 25, and a vertical ink stick assembly mounting hole 26 is provided on the chuck body 25, and the ink stick assembly can be suitably installed in the ink stick assembly mounting hole 26 Inside, the chuck body 25 is provided with a stepped hole 27 on the left side of the ink stick assembly mounting hole 26. The stepped hole 27 corresponds to the threaded hole 1 24, and three stepped holes 27 are correspondingly opened. 28 passes through the stepped hole and screws into the corresponding threaded hole 24 to realize the fixed connection between the chuck body 25 and the crossbeam 5. The stepped hole 27 can make the head of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com