Motor-driven ink grinding device

A kind of ink grinding and motorized technology, which is applied in the direction of ink table, ink container, printing, etc., can solve the problems of time-consuming and cumbersome ink grinding process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

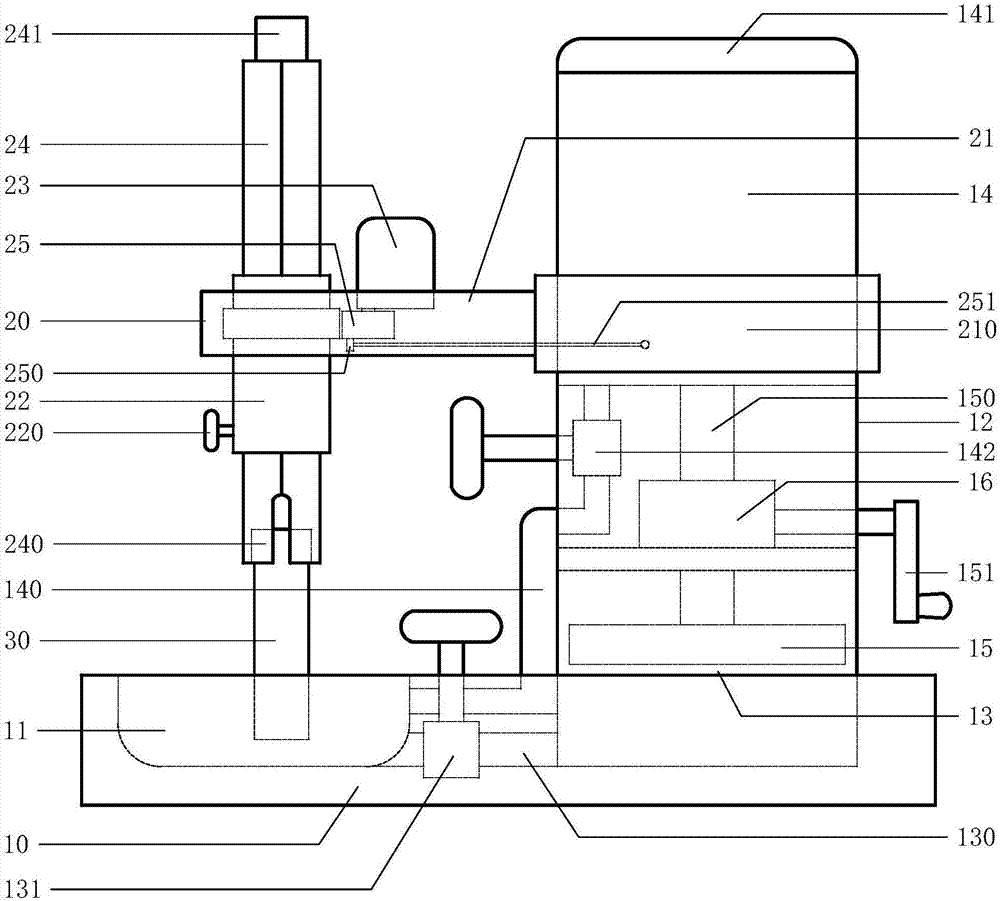

[0018] See attached figure 1 , the motorized ink grinding device of the present embodiment comprises an inkstone base frame 10 and a multi-action grinding ink arm 20, one side of the top surface of the inkstone type base frame 10 is provided with a grinding ink inkstone pool 11, and the other side is provided with a columnar box 12 , the bottom of the columnar box 12 is provided with an ink tank 13, and the top is provided with a clean water tank 14, and the ink tank 13 and the clean water tank 14 are all communicated with the inkstone pool 11 through a pipeline, and the ink tank 13 is provided with an ink pumping piston 15 and a piston advancing and retreating mechanism 16. The multi-action ink grinding arm 20 includes a cantilever arm frame 21, a rotating sleeve 22, an arm bar rotation machine 23 and an ink grinding arm bar 24. The cantilever arm The root of the frame 21 is provided with a positioning bushing 210, the positioning bushing 210 is connected with the cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com