Sample injector and microfluidic system

A technology of microfluidic control system and sample injector, which is applied in the direction of laboratory equipment, fluid controllers, and laboratory containers, etc. Stable sample, high injection precision, easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

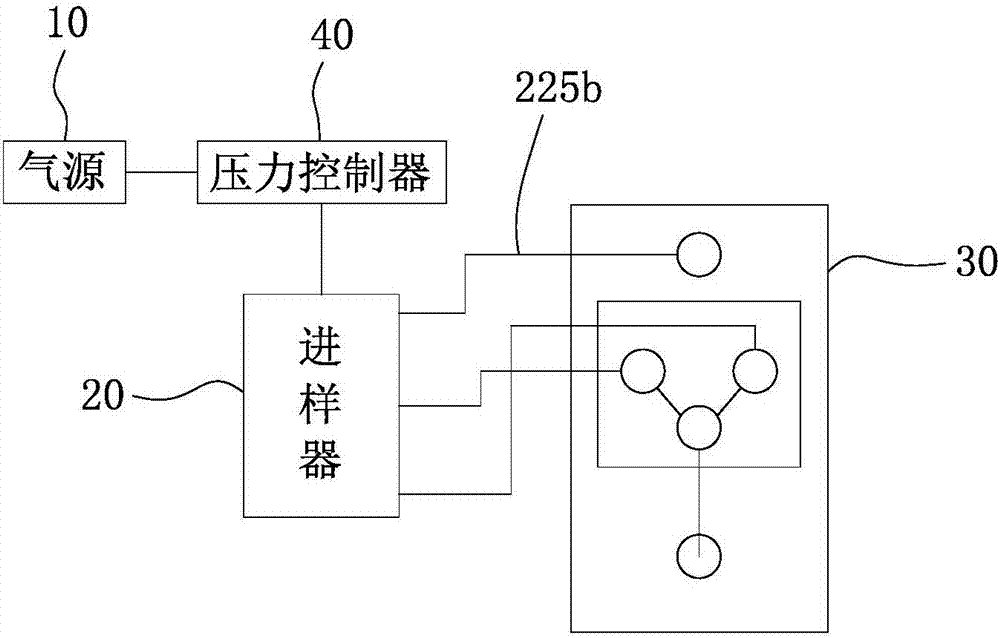

[0037] Such as figure 1 As shown, this embodiment provides a microfluidic system, including a gas source 10 , at least one sample injector 20 and a microfluidic chip 30 . The gas source 10 is connected to the sampler 20 , and the microfluidic chip 30 is connected to the sampler 20 . The high-pressure gas generated by the gas source 10 flows into the sampler 20 , and the high-pressure gas pushes the sample fluid in the sampler 20 out to the microfluidic chip 30 . The microfluidic chip 30 performs operations such as analysis, mixing, droplet generation, and cell encapsulation on the sample fluid.

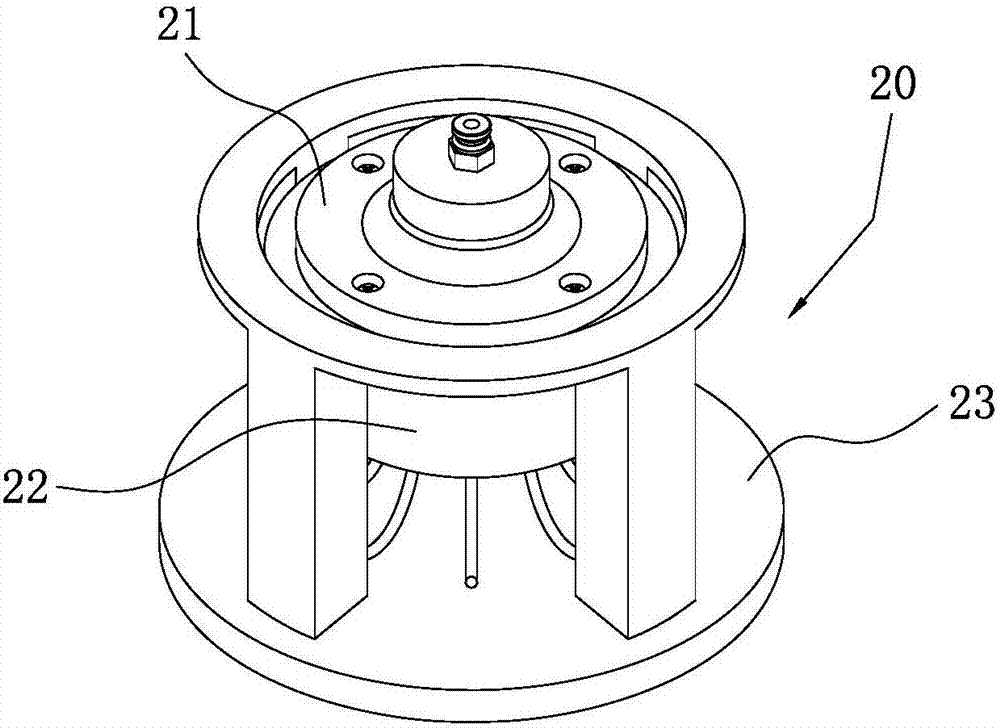

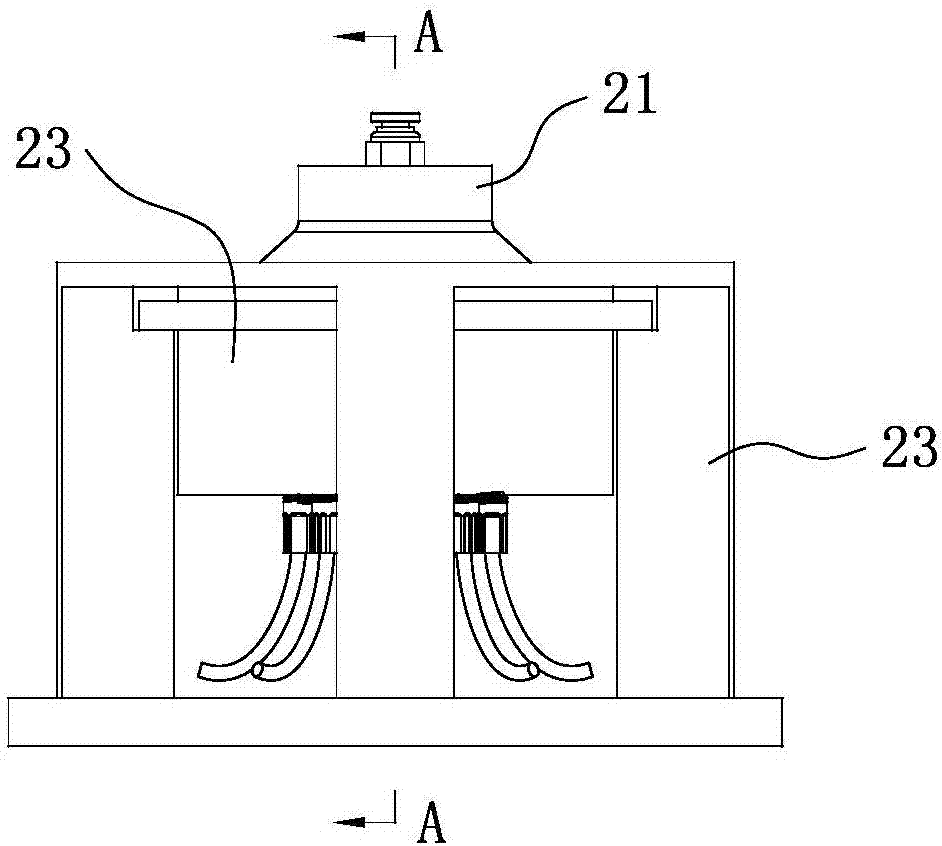

[0038] refer to Figure 2 to Figure 3 , The injector 20 includes an upper cover 21 , a lower housing 22 and a support seat 23 . The lower casing 22 is detachably installed on the supporting seat 23 . The upper cover 21 is sealed and deta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com