Thermoplastic low-smoke halogen-free flame-retardant polyolefin special material for oil filled bushing and preparation method thereof

An oil-filled bushing and thermoplastic technology, which is applied in the field of thermoplastic low-smoke halogen-free flame retardant polyolefin special material for oil-filled bushings and its preparation field, and achieves the effects of not easy to ignite and spread, reliable performance and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

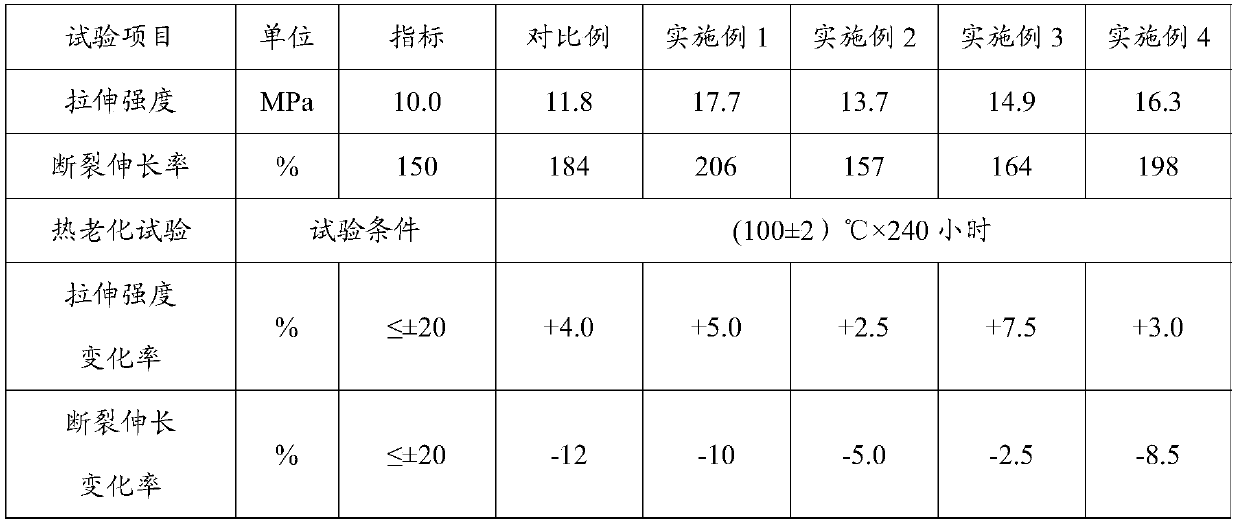

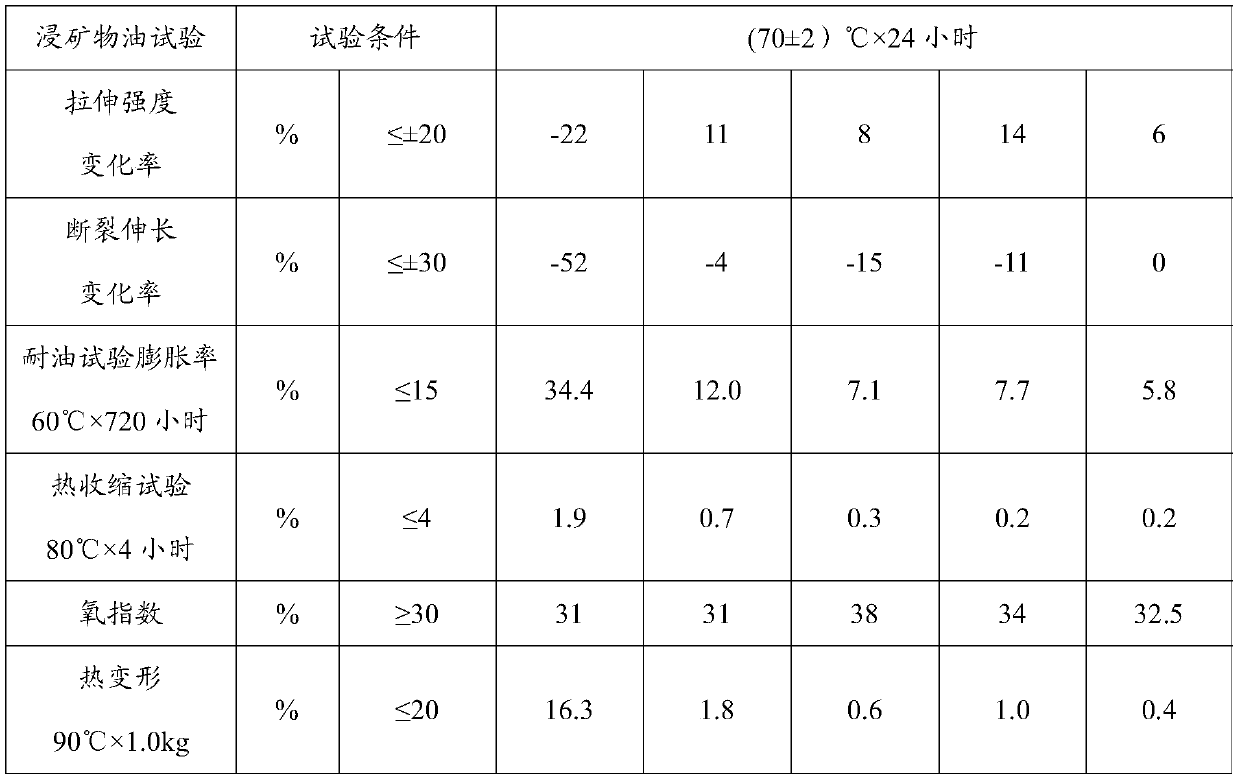

Examples

Embodiment 1

[0032] A kind of thermoplastic low-smoke halogen-free flame-retardant polyolefin special material for oil-filled casing, comprising by weight:

[0033] Copolypropylene PP5090T 15 parts;

[0034] High-density polyethylene 5502 25 parts;

[0035] Dynamic fully vulcanized thermoplastic polyolefin elastomer TSiV-POE 15 parts;

[0036] Ultra-low density polyethylene CLB0 25 parts;

[0037] 15 parts of the mixture (weight ratio is 1:2) of maleic anhydride grafted polypropylene and maleic anhydride grafted high-density polyethylene;

[0038] 1 part of high molecular weight polysiloxane;

[0039] 0.5 part of sorbitol nucleating agent;

[0040] 120 parts of mixture (weight ratio is 1:1:4) of hydromagnesite flame retardant, magnesium hydroxide and aluminum hydroxide;

[0041] 0.5 parts of microcrystalline nano-magnesium-lithium silicate composite char-forming agent;

[0042] 0.5 parts of vinyl siloxane or amino siloxane;

[0043] The mixture of Irganox1010 and Irganox168 (weight ...

Embodiment 2

[0047] A kind of thermoplastic low-smoke halogen-free flame-retardant polyolefin special material for oil-filled casing, comprising by weight:

[0048] Co-polypropylene PP5090T 25 parts;

[0049] High-density polyethylene 5502 10 parts;

[0050] Dynamic fully vulcanized thermoplastic polyolefin elastomer TSiV-POE 40 parts;

[0051] Ultra-low density polyethylene CLB0 10 parts;

[0052] 15 parts of a mixture (weight ratio is 1:1) of maleic anhydride grafted polypropylene and maleic anhydride grafted high-density polyethylene;

[0053] 5 parts of high molecular weight polysiloxane;

[0054] 0.1 part of sorbitol nucleating agent;

[0055] 180 parts of mixture (weight ratio is 1:1:4) of hydromagnesite flame retardant, magnesium hydroxide and aluminum hydroxide;

[0056] 2.5 parts of microcrystalline nano-magnesium-lithium silicate composite char-forming agent;

[0057] 2 parts of vinyl siloxane or amino siloxane;

[0058] 2 parts of the mixture of Irganox1010 and Irganox168...

Embodiment 3

[0062] A kind of thermoplastic low-smoke halogen-free flame-retardant polyolefin special material for oil-filled casing, comprising by weight:

[0063] Copolypropylene PP5090T 20 parts;

[0064] High-density polyethylene 5502 15 parts;

[0065] Dynamic fully vulcanized thermoplastic polyolefin elastomer TSiV-POE 30 parts;

[0066] Ultra-low density polyethylene CLB0 25 parts;

[0067] 10 parts of a mixture (weight ratio of 1:2) of maleic anhydride grafted polypropylene and maleic anhydride grafted high-density polyethylene;

[0068] 3.5 parts of high molecular weight polysiloxane;

[0069] 0.3 part of sorbitol nucleating agent;

[0070] 160 parts of mixture (weight ratio is 1:3:4) of hydromagnesite flame retardant, magnesium hydroxide and aluminum hydroxide;

[0071] 1.5 parts of microcrystalline nano-magnesium-lithium silicate composite char-forming agent;

[0072] 1.5 parts of vinyl siloxane or amino siloxane;

[0073] The mixture of Irganox1010 and Irganox168 (weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com