Gumming machine for producing decorative paper

A technology of gluing machine and decorative paper, applied in the field of gluing machine, can solve the problems of increasing the scrap rate, increasing the production cost, unable to guarantee the uniform gluing, etc., and achieving the effect of smooth gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

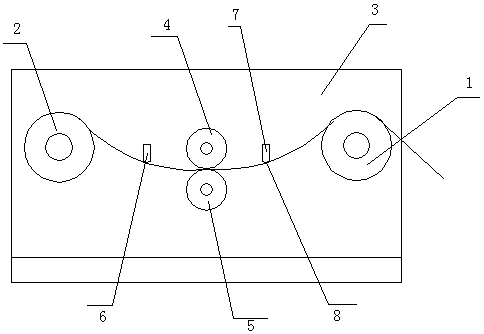

[0020] As shown in the figure, a gluing machine for decorative paper production includes a frame 1, and a rotatable rotating roller 2 fixed on the frame, a traction roller 3, a glue roller 4 and a pressure roller 5, and the glue roller Located above the pressure roller, the rotating roller and the traction roller are respectively located on both sides of the rubberizing roller, and the first limiting rod 6 and the second limiting rod 7 are arranged on the frame, and the first limiting rod is located on the rotating roller and between the glue roller, the second stop bar is located between the glue roller and the traction roller, and the tops of the first stop bar and the second stop bar are provided with a positioning protrusion 8, and the positioning protrusion is spherical cap structure;

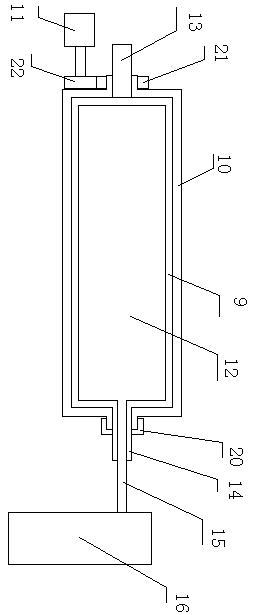

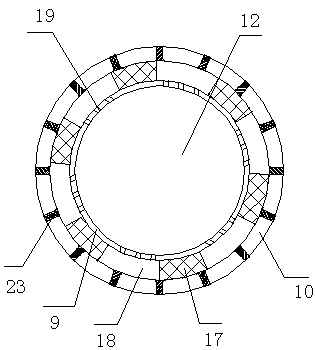

[0021] The glue-coating roller includes an inner roller body 9, an outer roller body 10 and a motor 11, the inner roller body is a hollow cylindrical structure, the inner roller body is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com