Uvioresistant nylon-6 fiber for ultrathin and light fabric and preparation method thereof

An anti-ultraviolet and anti-ultraviolet agent technology, which is applied in the fields of fiber chemical characteristics, melt spinning, stretch spinning, etc., can solve the problems of limited anti-ultraviolet functional particles, insufficient ultraviolet absorption, and increased addition of functional particles to protect the interior. Fastness, increase the effect of spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] An anti-ultraviolet nylon 6 fiber for ultra-thin and lightweight fabrics, which is composed of branched nylon 6 functional masterbatch and conventional nylon 6 slices, and its mass percentage is:

[0044] Branched chain nylon 6 functional masterbatch 6%

[0045] Regular nylon 6 slices margin

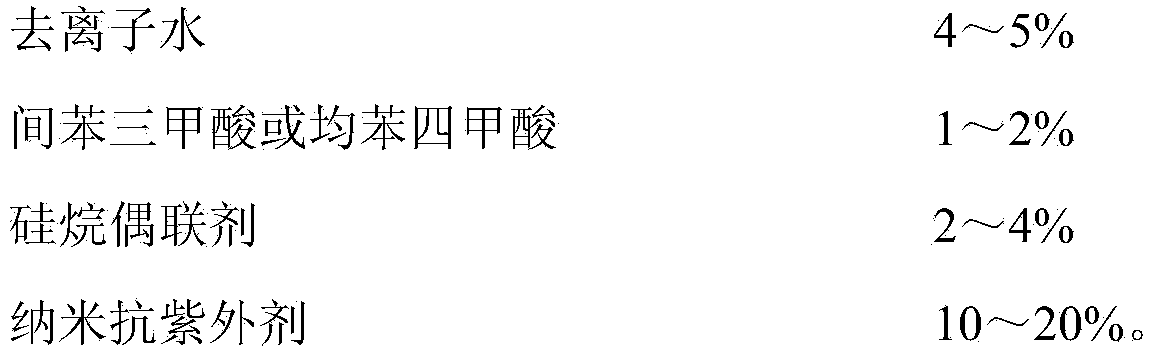

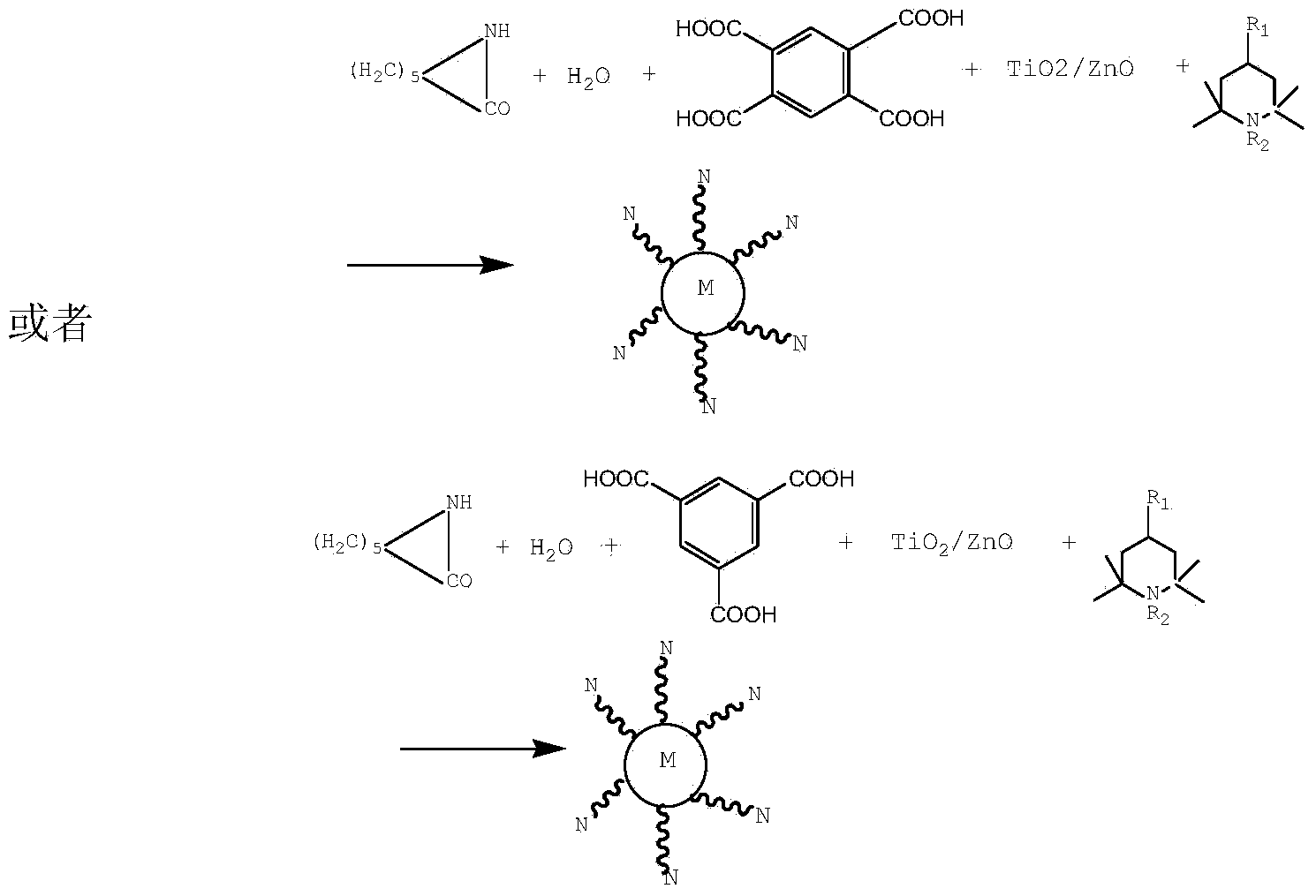

[0046]In-situ polymerization is optimally selected, and the in-situ polymerization branched chain nylon 6 functional masterbatch can be made of isophthalic acid, caprolactam, molecular weight regulator, deionized water, nano anti-ultraviolet agent, silane coupling agent, in nitrogen Prepared by polymerization reaction under protection, based on the caprolactam, the mass percentage of its raw material components is:

[0047]

[0048] The prepared branched nylon 6 chips have a relative viscosity of 2.3 and a melting point of 221° C., and the branched nylon 6 has low viscosity and high fluidity.

[0049] Described molecular weight regulator is adipic acid;

[0050] The silane c...

Embodiment 2

[0059] An anti-ultraviolet nylon 6 fiber for ultra-thin and lightweight fabrics, which is composed of branched nylon 6 functional masterbatch and conventional nylon 6 slices, and its mass percentage is:

[0060] Branched chain nylon 6 functional masterbatch 8%

[0061] Regular nylon 6 slices margin

[0062] In-situ polymerization is the best choice. The in-situ polymerization branched chain nylon 6 functional masterbatch can be made of pyromellitic acid, caprolactam, molecular weight regulator, deionized water, nano anti-ultraviolet agent, silane coupling agent, in nitrogen Prepared by polymerization reaction under protection, based on the caprolactam, the mass percentage of its raw material components is:

[0063]

[0064] The prepared branched nylon 6 chips have a relative viscosity of 2.2 and a melting point of 220° C., and the branched nylon 6 has low viscosity and high fluidity.

[0065] Described molecular weight regulator is acetic acid;

[0066] The silane coupli...

Embodiment 3

[0076] An anti-ultraviolet nylon 6 fiber for ultra-thin and lightweight fabrics, which is composed of branched nylon 6 functional masterbatch and conventional nylon 6 slices, and its mass percentage is:

[0077] Branched chain nylon 6 functional masterbatch 10%

[0078] Regular nylon 6 slices margin

[0079] In-situ polymerization is the best choice. The in-situ polymerization branched chain nylon 6 functional masterbatch can be made of isophthalic acid, caprolactam, molecular weight regulator, deionized water, nano anti-ultraviolet agent, silane coupling agent, Prepared by polymerization reaction under protection, based on the caprolactam, the mass percentage of its raw material components is:

[0080]

[0081]

[0082] The prepared branched nylon 6 chips have a relative viscosity of 2.1 and a melting point of 219° C., and the branched nylon 6 has low viscosity and high fluidity.

[0083] Described molecular weight regulator is adipic acid, acetic acid;

[0084] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com