Thermoplastically modified high-fluidity polyvinyl alcohol, and thermoplastically modified high-fluidity polyvinyl alcohol casting film material and preparation method thereof

A polyvinyl alcohol and high fluidity technology, applied in the field of high fluidity polyvinyl alcohol cast film material and its preparation, can solve the problems of poor melt flow performance, difficult processing, poor thermoplasticity of polyvinyl alcohol, etc. The effect of improved processability, good melt flow properties, and wider processing window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

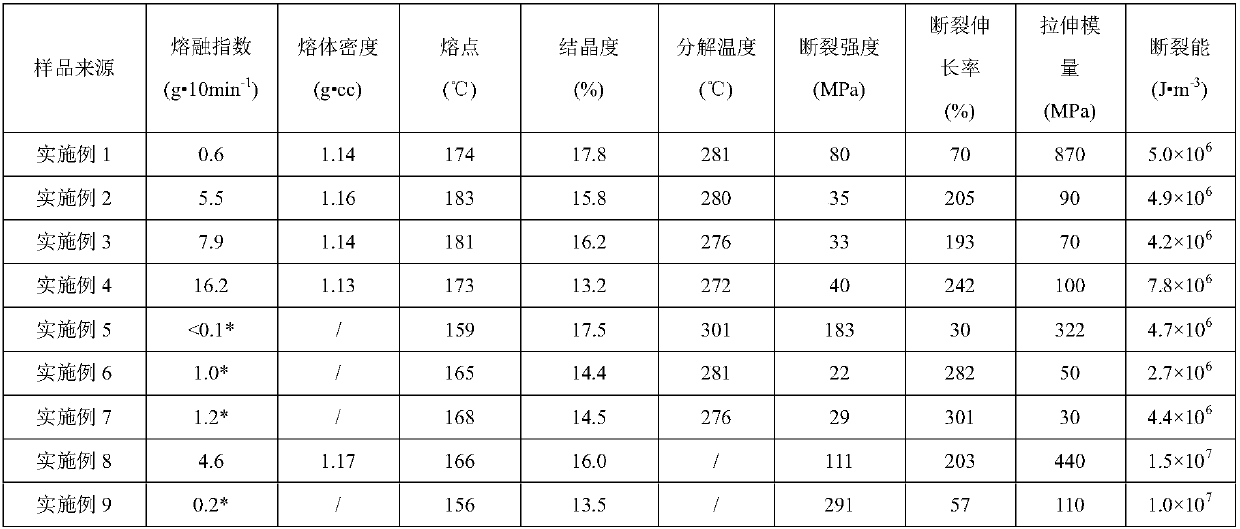

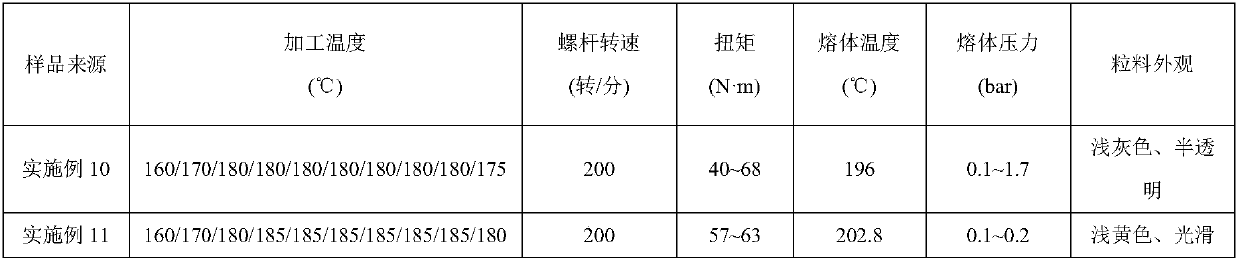

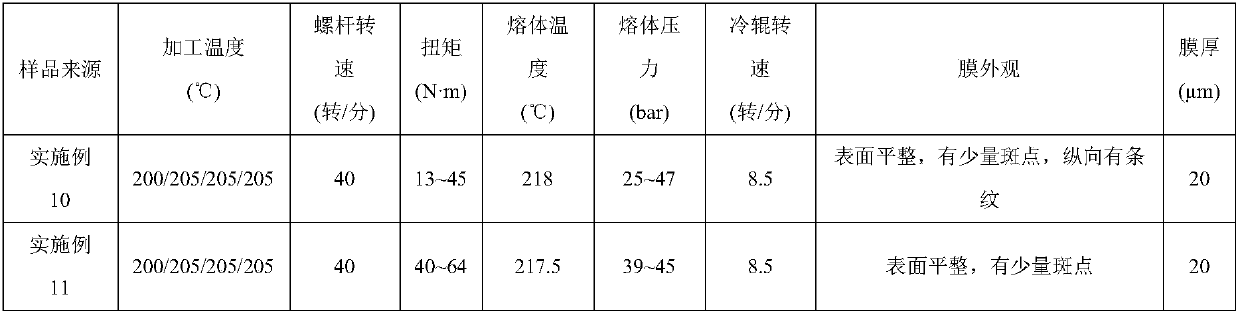

Examples

Embodiment 1

[0040] Thermoplastic modified polyvinyl alcohol processing technology: First, polyvinyl alcohol (PVA-1, alcoholysis degree 88%, polymerization degree 560, 4% weight percent concentration aqueous solution viscosity 7.8mPa·s) at 70℃, vacuum conditions Drying for 4 hours, vacuum packaging with apertsVS5500 vacuum fresh-keeping machine (Dongguan Yinger Electric Co., Ltd.), spare. Take 90 parts of PVA-1 and 10 parts of glycerin (Chemical Reagent Co., Ltd. of Sinopharm Group), respectively, from the weight loss feeder (Brabender TECHNOLOGIE DSR-18) and constant flow plunger pump (Dongtai Yanshan Instrument Factory, HLB-1008) Introduced into the Thermo SCIENTIFIC HAAKE PolyLab OS twin-screw extruder, the feed rate of polyvinyl alcohol is 0.54 kg / h, the feed rate of glycerin is 0.06 kg / h, the temperature of the extruder 1-9 and the die head The order is 150℃, 160℃, 170℃, 180℃, 180℃, 180℃, 180℃, 180℃, 170℃, 160℃, the screw speed is 200 rpm, the melt temperature is 177~179℃, the melt Th...

Embodiment 2

[0044] Thermoplastic modified polyvinyl alcohol processing technology: First, PVA-1 (PVA-1, alcoholysis degree 88%, polymerization degree 560, 4% weight percent concentration aqueous solution viscosity 7.8mPa·s) at 70℃, Dry for 4 hours under vacuum conditions, vacuum package, and reserve. Take 85 parts of PVA-1 and 15 parts of glycerin, and import them into Thermo SCIENTIFIC HAAKE PolyLab OS twin-screws from the Brabender TECHNOLOGIEDSR-18 and constant flow plunger pump (Dongtai Yanshan Instrument Factory, HLB-1008). In the extruder, the feed rate of polyvinyl alcohol is 0.57 kg / h, the feed rate of glycerol is 0.10 kg / h, the temperature of the extruder 1 to 9 and the die head are 150℃, 160℃, 165 ℃, 165℃, 165℃, 165℃, 165℃, 165℃, 165℃, 165℃, screw speed 200 rpm, melt temperature 193℃, melt pressure 0.1bar, torque 55~65N·m . After the extruded sample is cooled by wind, it is pelletized by COLLIN D-8017 pelletizer to obtain light yellow thermoplastic modified polyvinyl alcohol pe...

Embodiment 3

[0048] Thermoplastic modified polyvinyl alcohol processing technology: First, PVA-1 (PVA-1, alcoholysis degree 88%, polymerization degree 560, 4% weight percent concentration aqueous solution viscosity 7.8mPa·s) at 70℃, Dry for 4 hours under vacuum conditions, vacuum package, and reserve. Take 80 parts of PVA-1 and 20 parts of glycerin, and import them into Thermo SCIENTIFIC HAAKE PolyLab OS twin-screws from the Brabender TECHNOLOGIEDSR-18 and constant flow plunger pump (Dongtai Yanshan Instrument Factory, HLB-1008). In the extruder, the feed rate of polyvinyl alcohol is 0.48 kg / h, the feed rate of glycerol is 0.12 kg / h, the temperature of the extruder 1 to 9 and the die head are 150℃, 160℃, 165 ℃, 165℃, 165℃, 165℃, 165℃, 165℃, 165℃, 165℃, screw speed is 200 rpm, melt temperature is 192℃, melt pressure is 0.1bar, torque is 45~55N·m . After the extruded sample is cooled by wind, it is pelletized by COLLIN D-8017 pelletizer to obtain light yellow thermoplastic modified polyviny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com