Lithium-supplementing positive electrode slurry and preparation method and application thereof

A technology of positive electrode slurry and positive active material, which is applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of increasing the contact time of LNO powder with air and the inability to ensure the uniform dispersion of LNO particles, so as to reduce the impact, Improve the effect of the processing window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a lithium-supplementing cathode slurry, and the preparation method of the lithium-supplementing cathode slurry is as follows:

[0042](1) Mix N-methylpyrrolidone and polyvinylidene fluoride, add carbon nanotubes and conductive carbon black SP in turn for vacuum stirring, the dispersion speed is 2000rpm, and the dispersion time is 180min to obtain a half-step conductive glue;

[0043] (2) the half-step conductive adhesive solution that step (1) obtains and Li 2 NiO 2 After the lithium replenishing agent is mixed, it is stirred at 30 rpm, the dispersion speed of mixing is 2000 rpm, and the dispersion time is 90 minutes to obtain a conductive glue. The mass fraction of LNO in the conductive glue is 10%, the mass fraction of carbon nanotubes is 1%, and the SP The mass fraction of the product is 2%;

[0044] (3) Add conductive glue to the NCM powder for the first time, control the overall solid content of the slurry to 93%, stir and disperse for 60...

Embodiment 2

[0048] The only difference between this embodiment and embodiment 1 is that the mixing and dispersing speed of the conductive glue solution in step (2) is 500 rpm, and other conditions and parameters are exactly the same as those in embodiment 1.

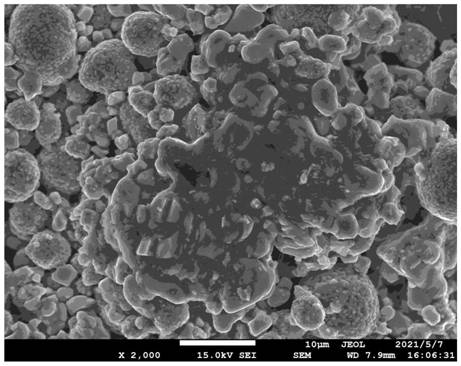

[0049] The dispersion diagram of the lithium-supplementing positive electrode slurry is as follows: image 3 shown by image 3 It can be seen that slight agglomeration of the positive electrode slurry prepared in this embodiment occurs.

Embodiment 3

[0051] The only difference between this embodiment and embodiment 1 is that the mixing and dispersing speed of the conductive glue solution in step (2) is 3500 rpm, and other conditions and parameters are exactly the same as those in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com