Patents

Literature

48 results about "Poly-beta-hydroxybutyric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible modified method for poly beta-hydroxybutyric butyrate and poly beta-hydroxybutyric butyrate-beta hydroxyl valerate

This invention relates to a toughness modify method of e. Poly-beta-hydroxybutyric acid ester and poly-beta-hydroxybutyric acid ester-beta-hydroxy valerate and poly- succinic acid butanediol ester or poly- lactic acid carry out vacuum drying, then according to a certainty weight proportion add to Banbury mixer for fusion and blending, after several minutes, add cross-linking agent to carry out dynamic co crosslinking. This materials breaking elongation rate can reach 425%, fracture strength can reach 33.5 MPa, notch impact strength reach 64 joule / m.

Owner:SHANGHAI JIAO TONG UNIV

Shell powder modified polylactic acid composite material, preparation method and applications thereof

The invention discloses a shell powder modified polylactic acid composite material, wherein the preparation raw materials of the composite material comprise: shell powder modified polylactic acid granules, poly beta-hydroxybutyric acid, polyvinyl alcohol, polycaprolactone, polylactic acid fibers and shell powder B, the preparation raw materials of the shell powder modified polylactic acid granulescomprise: polylactic acid, shell powder A, a surfactant, a silane coupling agent, polyethylene glycol and / or a polyethylene glycol acrylate compound, a chitosan grafted copolymer and a dehydrating agent, the particle size of the shell powder A is 1-10 [mu]m, the particle size of the shell powder B is 1-5 [mu]m, and the particle size of the shell powder A is greater than the particle size of the shell powder B. According to the present invention, the composite material has advantages of strong mechanical property, good heat resistance, good adsorbability and good biodegradability, is an environmentally-friendly and pollution-free novel composite material, and is suitable for indoor and vehicle interior decoration materials, cosmetics or food packaging materials.

Owner:深圳市氩氪新材料技术研究服务有限公司

Decomposable plastics containing starch and preparaton method

The plastic is mixture prepared from starch, poval, poly beta-hydroxybutyric acid ester or maleic anhydride grafted with poly beta-hydroxybutyric acid ester. The preparing method includes mixing starch in certain ratio with one or above materials of poval, poly beta-hydroxybutybic acid ester and said maleic anhydride, applying placticizer on the mixture and placing them in sealed bag at room temperature, taking out the material in bag and feeding it into extruder, and obtaining desired product through extruding, pelletizing and injection moulding.

Owner:TSINGHUA UNIV

Environment-friendly plastic material

The invention discloses an environment-friendly plastic material which comprises the following raw materials in parts by weight: 20-25 parts of polycaprolactone PCL, 65-70 parts of modified poly-beta-hydroxybutyric acid PHB, 13-18 parts of peanut protein flour, 1.5-1.8 parts of jute fiber, 3-4 parts of wood fiber, 1.1-1.3 parts of a silane coupling agent KH, 2-3 parts of sodium lactate, 1.1-1.6 parts of sodium diacetate, 2-2.2 parts of diisononyl phthalate, 5-7 parts of epoxy tall oil acid butyl ester, 2-4 parts of oxidized starch, 20-23 parts of nano white carbon black, 6-8 parts of light calcium carbonate, 3-5 parts of sea-foam stone powder and 1-1.4 parts of an antioxidant 1010, wherein the modified poly-beta-hydroxybutyric acid PHB is prepared by blending and modifying poly-beta-hydroxybutyric acid PHB and high cis-butadiene rubber. The environment-friendly plastic material can be degraded by microbes and is low in decomposition rate, high in oxidation resistance and impact resistance and low in water-absorbing quality.

Owner:汕头市纳川塑胶制品有限公司

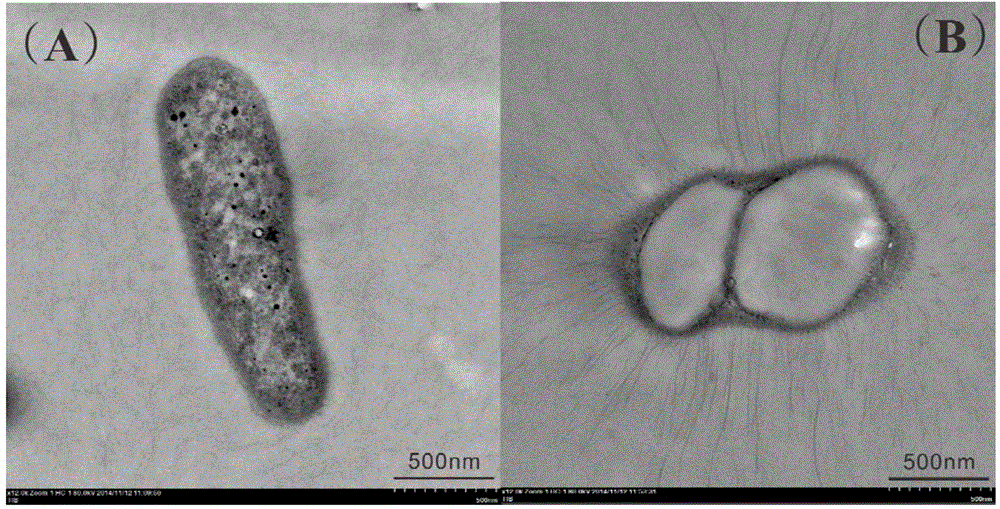

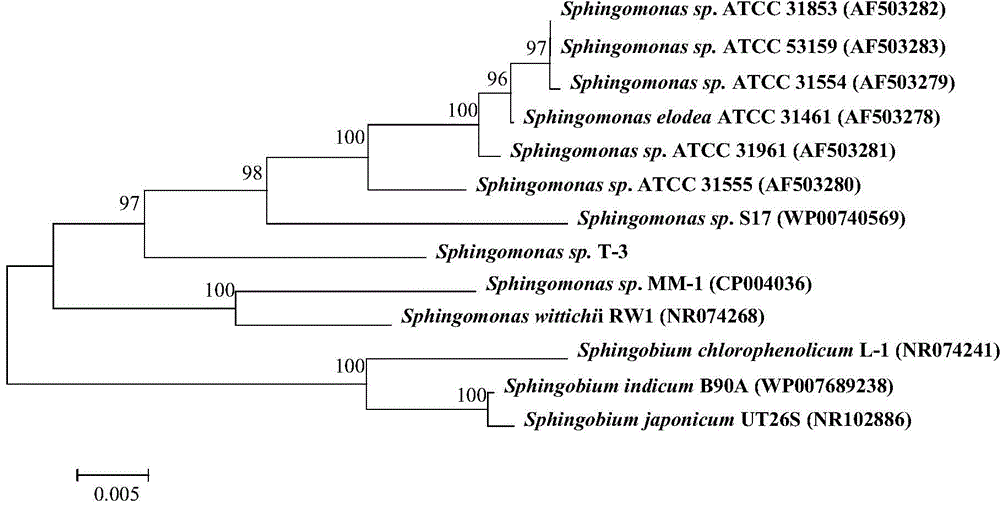

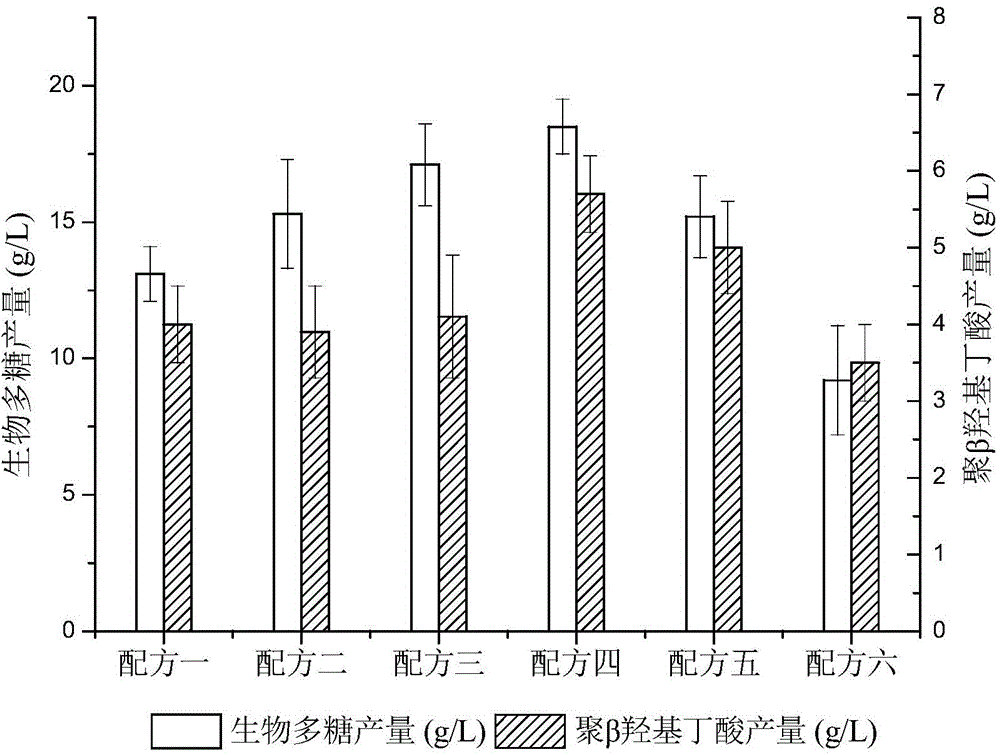

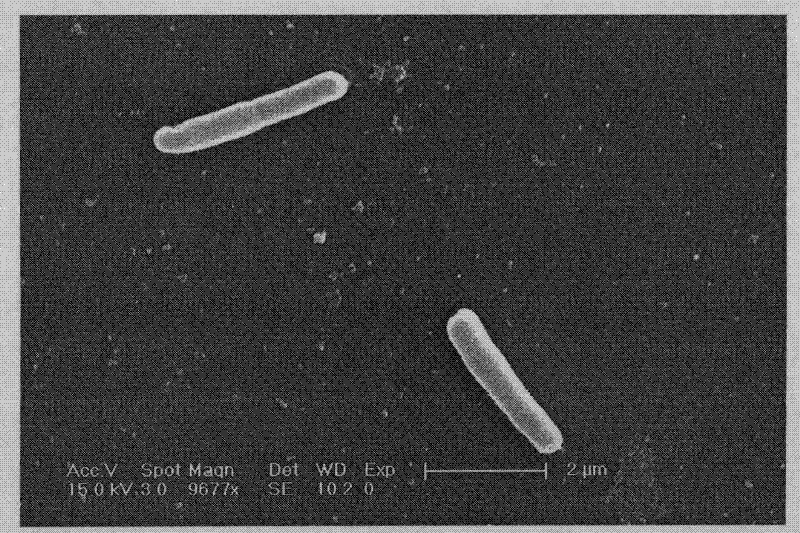

Sphingomonas sp. T-3 and method for producing biological polysaccharide and poly-beta-hydroxy-butanoic acid by co-fermentation

ActiveCN104651284AGood thickening effectGood shear thinning propertiesBacteriaMicroorganism based processesBiotechnologyFermentation

The invention relates to a Sphingomonas sp. T-3 and a method for producing biological polysaccharide and poly-beta-hydroxy-butanoic acid by co-fermentation. The collection number of the Sphingomonas sp. strain T-3 is CGMCC No.10150. The method comprises the following steps: carrying out activating culture on the strain T-3, inoculating into a seed culture medium, inoculating a seed solution into the fermentation culture medium, and culturing; and after the fermentation finishes, diluting with distilled water, heating, carrying out membrane separation to obtain a supernate and a thallus precipitate; regulating the pH value of the supernate to 3.0 or so with hydrochloric acid, regulating the pH value of the obtained precipitate to neutrality with NaOH, and drying to obtain the biological polysaccharide; and drying the thallus precipitate, extracting with chloroform, and drying the supernate to obtain the poly-beta-hydroxy-butanoic acid. In the strain T-3 fermentation process, abundant poly-beta-hydroxy-butanoic acid is accumulated in the cells, and abundant biological polysaccharide is secreted into the culture medium; and the two obtained products can be widely used in the fields of industry, food, medical treatment and the like.

Owner:NANKAI UNIV

Pseudomonas and application thereof to degrading macromolecular synthetic plastics

InactiveCN102181378AHas degradative propertiesBacteriaMicroorganism based processesPlastic wastePseudomonas

The invention belongs to the fields of microbial biotechnology and environmental biotechnology, particularly relates to pseudomonas and application thereof to degrading some macromolecular synthetic plastics. The pseudomonas is Pseudomonas sp. DS1001; a colony of the pseudomonas is circular and yellow white and has a smooth surface and a tidy edge; the thallus is in the shape of a short rod and is gram negative, has flagellum and does not have spore or capsule; a macromolecular compound such as polylactic acid (PLA), poly-beta-hydroxybutyric acid (PHB), polycaprolactone (PCL) and the like can be used as a unique carbon source for growth; and the pseudomonas has a high-efficiency degradation effect on the compounds. The pseudomonas can be applied to treatment and biological recycling of plastic wastes taking the macromolecular material as a main component.

Owner:NORTHEAST NORMAL UNIVERSITY

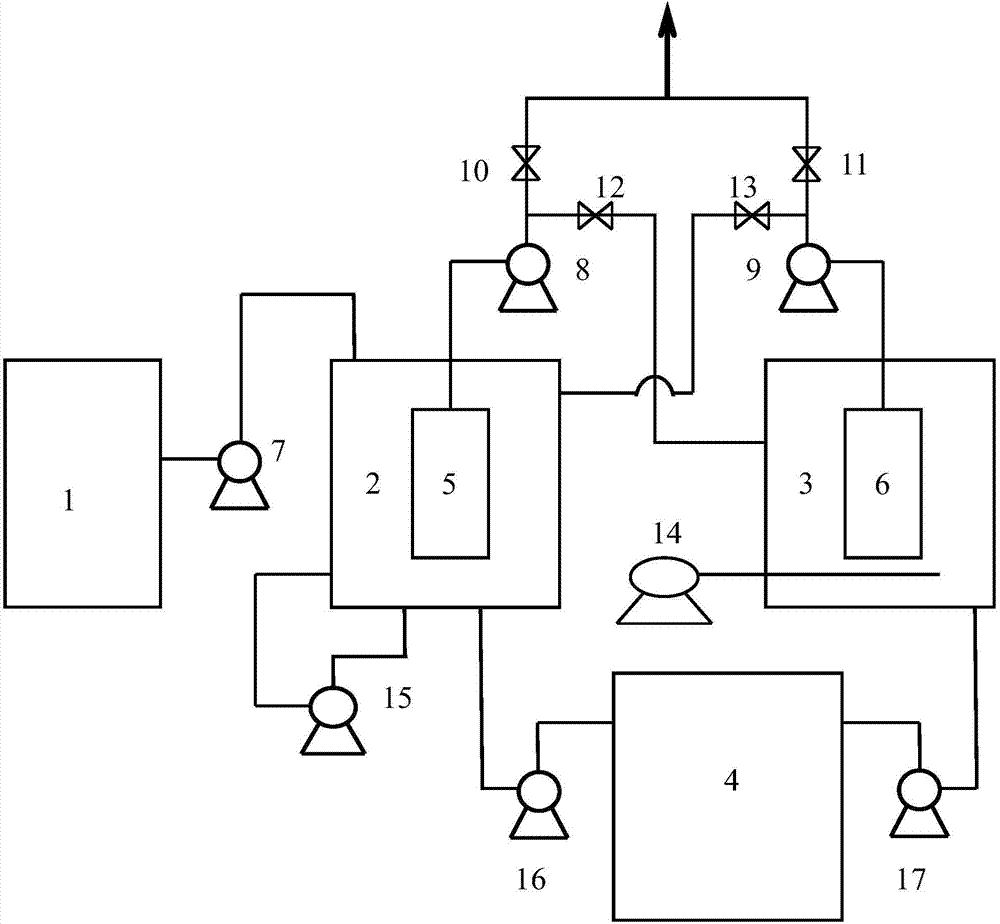

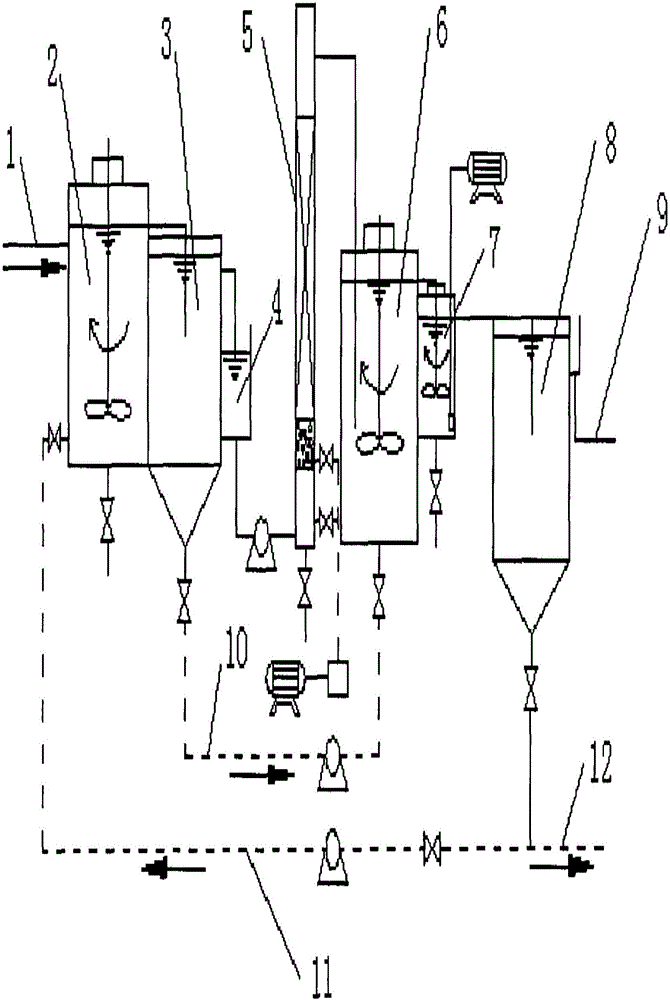

Double-membrane double-circulation sewage treatment process for enhancing denitrifying phosphorus removal

InactiveCN103755025AAchieve separationAvoid interactionTreatment with aerobic and anaerobic processesFiltrationWater quality

The invention relates to a double-membrane double-circulation sewage treatment process for enhancing denitrifying phosphorus removal. An anaerobic / anoxia membrane bioreactor and an aerobic membrane bioreactor are connected in series so as to enhance denitrifying phosphorus removal through a double-membrane filtration two-way circulation mode. The double-membrane double-circulation sewage treatment process comprises the steps of: firstly, carrying out anaerobic phosphorus release on phosphorus-accumulating bacteria under anaerobic condition, and storing organic matters in inflowing water as poly-beta-hydroxybutyric acid; then circulating supernate subjected to anaerobic phosphorus release to the aerobic membrane bioreactor for carrying out aerobic nitrification and degrading organic matters through a membrane assembly, circulating nitrifying liquid in the aerobic membrane bioreactor to the anaerobic / anoxia membrane bioreactor for carrying out denitrifying phosphorus removal through the membrane assembly; then filtering effluent water by utilizing the membrane assembly, and finally discharging phosphorous-rich sludge, thus realizing the phosphorous removal. According to the double-membrane double-circulation sewage treatment process, the thorough separation of nitrobacterium and phosphorous-accumulating bacteria can be realized, the carbon source competence of different microorganisms and sludge age conflict in the traditional denitrification and phosphorous removal processes can be solved, and the carbon sources and running cost can be saved; the membrane filtration can meet the requirement on the quality of sewage recycled water; the process is simple in flow and convenient to operate.

Owner:CHINA UNIV OF MINING & TECH

Protein plastic material

The invention discloses a protein plastic material comprising the following raw materials in parts by weight: 45-50 parts of PBS (poly butylenes succinate), 30-35 parts of poly-beta-hydroxybutyric acid (PHB), 20-25 parts of peanut protein powder, 2.5-3 parts of potassium titanate fiber, 5-7 parts of silk fiber, 1.2-1.7 parts of a silane coupling agent KH570, 2-3 parts of sodium sorbate, 1.1-1.6 parts of ethyl p-hydroxybenzoate, 1.7-1.9 parts of diisooctyl phthalate (DIOP), 3-6 parts of epoxidized soybean oil, 3-5 parts of starch acetate, 15-18 parts of talcum powder, 7-11 parts of wollastonite powder, 5-9 parts of calcite powder and 1-1.4 parts of tert-butylhydroquinone (TBHQ). The protein plastic material disclosed by the invention can be decomposed by microorganisms, and is strong in ductility and good in impact resistance and oxidation resistance, the generation of white pollution can be avoided and the consumption of agricultural product resources can also be reduced.

Owner:威海正森新材料科技有限公司

Modified environmental protection plastic with high ductility, impact resistance and oxidation resistance

The invention discloses modified environmental protection plastic with high ductility, impact resistance and oxidation resistance. The modified environmental protection plastic comprises the following raw materials in parts by weight: 45-50 parts of poly butylenes succinate (PBS), 30-35 parts of poly-beta-hydroxybutyric acid (PHB), 20-25 parts of peanut protein powder, 2.5-3 parts of potassium titanate fiber, 12-15 parts of coconut fiber, 1.2-1.7 parts of a silane coupling agent KH570, 2-3 parts of sodium sorbate, 1.1-1.6 parts of ethyl p-hydroxybenzoate, 1.4-1.6 parts of dioctyl phthalate (DOP), 1,2-1.6 parts of zinc stearate, 3-5 parts of starch acetate, 15-18 parts of talcum powder, 7-11 parts of wollastonite powder, 5-9 parts of calcite powder, 7-11 parts of sepiolite,1-1.4 parts of tertiary butyl hydroquinone (TBHQ) and 1-1.4 parts of 2,6-di-tert-butyl-4-methylphenol (BHT). The modified environmental protection plastic disclosed by the invention can be decomposed by microorganisms and is high in ductility and good in impact resistance and oxidation resistance.

Owner:珠海市安迪尔生物科技有限公司

High-efficiency medium for synergistic illumination fermented panus giganteus and preparation method therefor

InactiveCN105130634APromote absorptionImprove developmentBio-organic fraction processingOrganic fertiliser preparationDecompositionMicrosphere

The present invention discloses a high-efficiency medium for synergistic illumination fermented panus giganteus. The high-efficiency medium comprises the following components in parts by weight: poly-beta-hydroxybutyric acid microspheres with high biological activity, porous chitosan light and heat rich absorbing microspheres rich in amino-acids, sawdust powder, coconut palm powder, coffee grounds, soybean meal, photosynthetic bacteria inoculant, bacillus subtilis inoculant, peptone and saccharomycetes. According to the present invention, yeasts absorbed and loaded by the porous chitosan light and heat rich absorbing microspheres rich in amino-acids are used for fermenting the sawdust powder, coconut palm powder, coconut flour, coffee grounds with high probiotic activity, soybean meal and wheat germ powder under a light condition to prepare a high-efficiency medium for panus giganteus, and the panus giganteus is rapid in heating rate, high in fermentation speed and decomposition degree of substrates and balanced in nutritive substances of the medium. The photosynthetic bacteria inoculant loaded by the poly-beta-hydroxybutyric acid microspheres with high biological activity used in the fruit-body growing process of panus giganteus cultivation can assist to promote the development and growth of the panus giganteus fruit-body and provide the guarantee for panus giganteus cultivation.

Owner:MAANSHAN ANKANG FUNGUS IND

High-hardness degradable plastic for electric apparatus elements

The invention discloses a high-hardness degradable plastic for electric apparatus elements. The high-hardness degradable plastic comprises the following raw materials in parts by weight: 60-90 parts of ABS resin, 20-40 parts of polyamide, 5-15 parts of polyhydroxybutyrate, 2-10 parts of furfuryl alcohol resin, 4-12 parts of glass fibers, 4-8 parts of zinc stearate, 2-6 parts of sodium carbonate, 1-6 parts of calcium carbonate, 2-5 parts of urea-formaldehyde resin, 5-15 parts of modified corn starch, 2-8 parts of vegetable protein cellulose, 1-9 parts of wood fiber powder, 3-9 parts of clay, 2-6 parts of white carbon black, 1-5 parts of benzophenone, 4-8 parts of poly-beta-hydroxybutyric acid, 1-3 parts of a dispersant, 2-5 parts of a plasticizer and 3-6 parts of a coupling agent. The plastic for the electric apparatus elements, disclosed by the invention, is high in hardness and is degradable.

Owner:ANHUI GUANGYUAN TECH DEV

Modified environment-friendly plastic with high elasticity

The invention discloses a modified environment-friendly plastic with high elasticity. The modified environment-friendly plastic comprises the following raw materials in parts by weight: 50-60 parts of ethylene-vinyl acetate copolymer, 45-55 parts of polyethylene resin, 18-22 parts of hydroxybutyrate-hydroxyvalerate copolyester, 12-15 parts of modified poly-beta-hydroxybutyric acid, 15-20 parts of oxidized starch, 10-15 parts of styrene-butadiene-styrene block copolymer, 1.5-1.8 parts of carbon fibers, 3-4 parts of cotton fibers, 1.1-1.3 parts of silane coupling agent, 2-3 parts of methylparaben, 1.1-1.6 parts of potassium sorbate, 2-2.2 parts of epoxy fatty acid octyl ester, 5-7 parts of tricresyl phosphate, 6-8 parts of precipitated barium sulfate, 3-5 parts of calcined kaolin, 23-26 parts of fumed titania and 1-1.4 parts of antioxidant. The modified environment-friendly plastic has high elasticity and excellent tensile strength, elongation at break and thermal aging property and can not cause irreversible harms to the environment.

Owner:ZIBO KUAKE MEDICINE TECH

Polyvinyl chloride plastic cable material with good thermal insulation property

InactiveCN106810741AImprove insulation effectIncrease spacingPlastic/resin/waxes insulatorsSodium BentoniteThermal insulation

The invention discloses a polyvinyl chloride plastic cable material with a good thermal insulation property. The polyvinyl chloride plastic cable material comprises the following raw materials in parts by weight: 15-35 parts of polyvinyl chloride, 10-20 parts of polyethylene, 5-12 parts of cardanol formaldehyde resin, 0.5-1.2 parts of urea, 5-15 parts of coconut fiber, 1-3 parts of a titanate coupling agent, 5-10 parts of silk fiber, 2-6 parts of modified montmorillonite, 2-6 parts of calcined kaolin, 1-8 parts of bentonite, 1-3 parts of an antistatic agent, 2-10 parts of poly-beta-hydroxybutyric acid, 2-6 parts of potassium titanate fiber, 0.2-0.6 part of di-octyl phthalate, 0.2-0.6 part of epoxidized soybean oil, 1-3 parts of sulfonated fish oil, 1-3 parts of tert-butyl hydroquinone and 2-8 parts of rosin. The polyvinyl chloride plastic cable material with the good thermal insulation property, disclosed by the invention, has the advantages of perfect thermal insulation property, high biodegradability, high stretch resistance and impact resistance and low water absorption rate.

Owner:安徽新立电缆材料有限公司

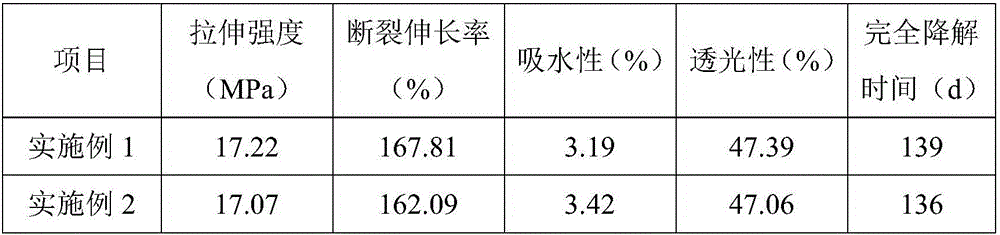

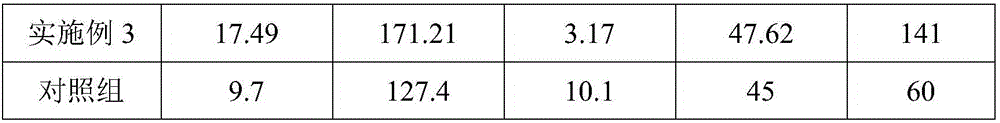

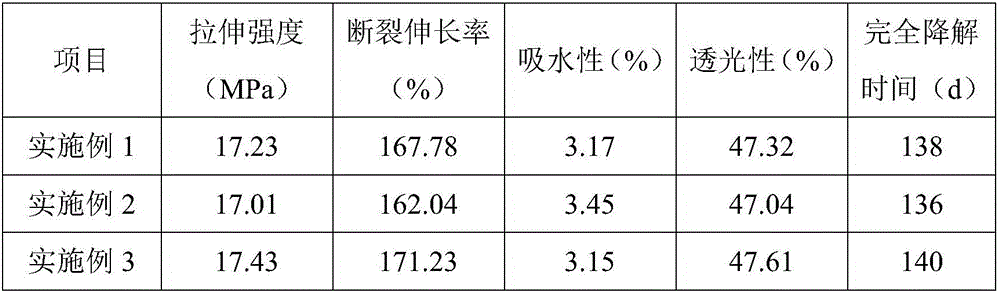

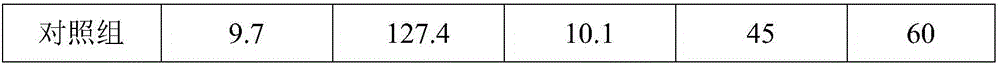

Degradable environmental-friendly plastic

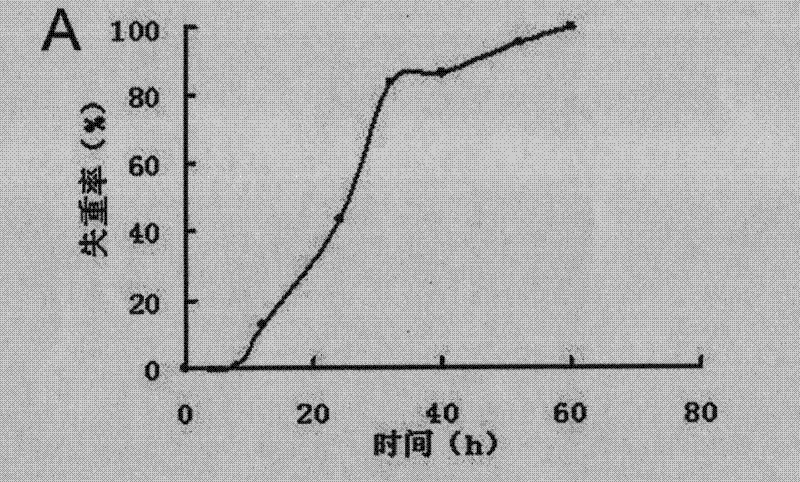

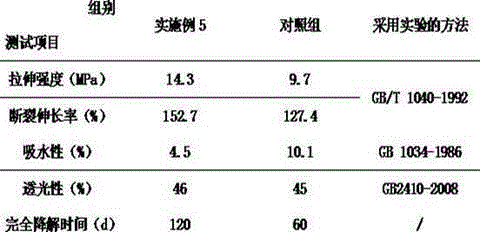

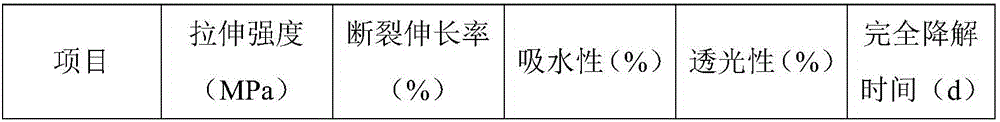

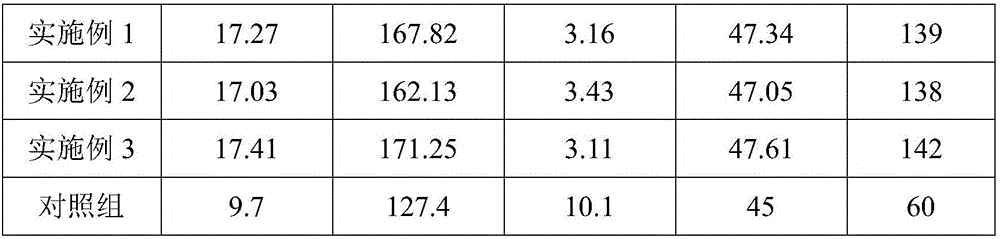

InactiveCN106167607AHigh tensile strengthHigh elongation at breakLow-density polyethyleneAntioxidant

The invention discloses degradable environmental-friendly plastic which comprises the following raw materials: polylactic resin, modified poly-beta-hydroxybutyric acid PHB, dinonyl phthalate DINP, pentaerythritol rosin ester, mung bean protein, oxidized cassava starch, alkali hargil, calcium carbonate, musa textilis fiber, linear low density polyethylene-graft-maleic anhydride, gamma-glycidoxy propyl trimethoxy silane, a methyl methacrylate-butadiene-styrol copolymer, aluminum potassium sulfate, citrate, an ethylene-vinyl acetate copolymer, ethylene bis-oleamide, diphenyl-methane-diisocyanate, an anti-mold antibacterial agent, a degradation agent, an antioxidant, a stabilizing agent, a flame retardant, a smoke inhibitor, a tackifier, a softening agent and an ultraviolet light absorber. The degradable environmental-friendly plastic disclosed by the invention is relatively good in tensile strength and elongation at break, good in impact resistance, relatively low in water absorption, good in light transparency, and free of damage to the environment as the plastic can be completely degraded into carbon dioxide and water after 136-141 days.

Owner:冯可发

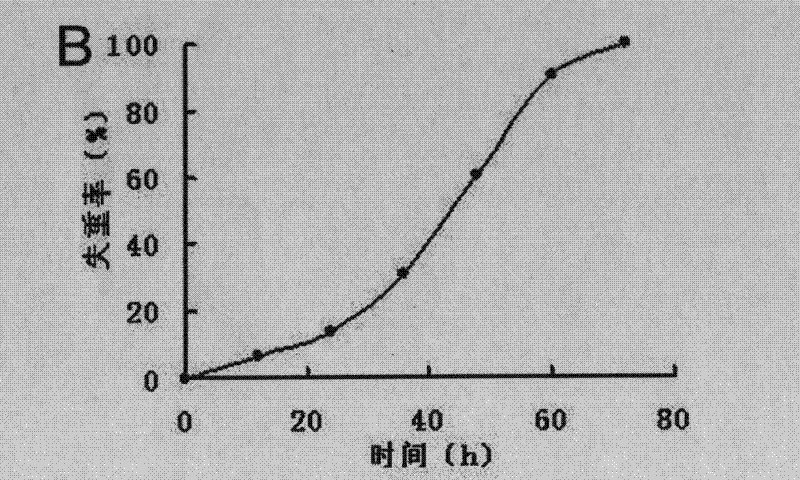

Degradable plastic

InactiveCN106189145AHigh tensile strengthHigh elongation at breakLow-density polyethyleneLinear low-density polyethylene

The invention discloses a degradable plastic which is prepared from polylactic resin, modified poly-beta-hydroxybutyric acid PHB, diisononyl phthalate DINP, unsaturated polyester resin, pea albumen powder, oxidized corn starch, alkaline hargil, calcium carbonate, ramie, linear low density polyethylene grafted maleic anhydride, gamma-glycidoxy propyl trimethoxy silane, methyl methacrylate butadiene styrene copolymer, aluminium potassium sulfate, tricaprylyl citrate, ethylene-vinyl acetate copolymer, ethylene bis oleamide, diphenylmethane diisocyanate, antimycotic antibacterial agent, degradation agent, antioxidant, stabilizing agent, flame retardance, smoke inhibitor, thickening agent, softening agent and ultraviolet light absorber. The degradable plastic has good tensile strength and elongation at break, is good in impact resistance, low in hydroscopicity and good in light transmission, can be completely degraded into carbon dioxide and water after 136-140 days, and no harm is produced to environment.

Owner:冯可发

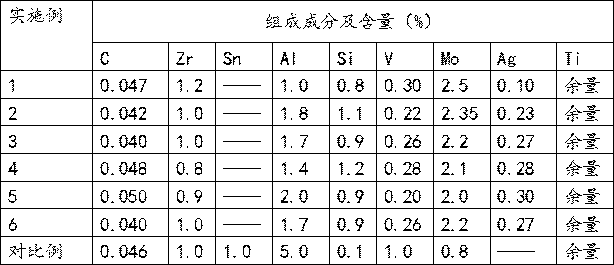

Titanium alloy drinking water filter element

InactiveCN109833780AFull and effective filtrationNot easy to corrodeSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWater filterTitanium alloy

The invention discloses a titanium alloy drinking water filter element. The filter element comprises a skeleton layer and a titanium alloy fiber layer, the skeleton layer is a porous structure formedby a ceramic material, a filter membrane is adhered to the titanium alloy fiber layer, the filter membrane is formed by spinning poly-beta-hydroxybutyric acid, and the thickness of the filter membraneis 10-100 [mu]m.

Owner:CHENGDU SHENGERJIA SCI & TECH

Novel plastic

InactiveCN106046730AHigh tensile strengthHigh elongation at breakFiberLinear low-density polyethylene

The invention discloses a novel plastic, which comprises the following raw materials: a polylactic acid resin, modified poly-beta-hydroxybutyric acid PHB, diisononyl phthalate DINP, octadecyl acrylate, mung bean protein powder, oxidation sweet potato starch, basic white clay, calcium carbonate, bamboo fiber, linear low density polyethylene grafted maleic anhydride, gamma-glycidyl ether oxypropyl trimethoxysilane, a methyl methacrylate-butadiene-styrene copolymer, potassium aluminum sulfate, citrate, an ethylene-vinyl acetate copolymer, N,N'-ethylenebisoleamide, diphenyl methane diisocyanate, an antifungal antimicrobial agent, a degradation agent, an antioxidant and a stabilizer. The novel plastic of the present invention has advantages of good tensile strength, good elongation at break, good impact resistance, low water absorption, and good light transmittance, can be completely degraded into carbon dioxide and water after 133-137 days, and cannot cause harm on the environment.

Owner:GUANGXI NANNING ZHICUI SCI TECH CONSULTATION CO LTD

Environment-friendly poly-beta-hydroxybutyric acid plastic material

The invention discloses an environment-friendly poly-beta-hydroxybutyric acid plastic material. The environment-friendly poly-beta-hydroxybutyric acid plastic material is composed of raw materials including, by weight part, 15-20 parts of corn starch, 8-12 parts of 5-7% polyvinyl alcohol solution, 0.5-0.8 part of 25-35% crosslinking agent and glycol water solution, 8-12 parts of cashew phenolic resin, 25-30 parts of poly-beta-hydroxybutyric acid, 5-8 parts of potassium titanate fiber, 2-3 parts of gamma-(methylacryloyl oxygen) methyl propyl trimethoxy silane, 2-2.5 parts of ethyl p-hydroxybenzoate, 1.5-2 parts of di-2-ethylhexyl phthalate, 0.5-0.8 part of urea, 5-8 parts of epoxidized soybean oil, 4-8 parts of silk fiber, 5-8 parts of starch acetate, 20-25 parts of talcum powder, 15-20 parts of calcite powder, 2-2.5 parts of tert-butylhydroquinone, 20-25 parts of glycerol and 15-18 parts of distilled water. The environment-friendly poly-beta-hydroxybutyric acid plastic material is environmentally friendly, high in biodegradation performance and waterproof performance and excellent in ageing-resistant performance and mechanical performance.

Owner:GUANGDONG KAIYU SCI & EDUCATION CULTURE CO LTD

Preparation method of high-sealing film for paper-plastic composite bag

The invention discloses a preparation method of a high-sealing film for a paper-plastic composite bag. The preparation method comprises the following steps: uniformly mixing polytetrafluoroethylene with polyethylene terephthalate, performing irradiating treatment, carrying out air exhausting and air removal, adding talcum powder and a silane coupling agent, grinding all above substances, adding epoxy tall oil, and performing stirring to obtain a first material; stirring poly-beta-hydroxybutyric acid, polylactic acid, microcrystalline cellulose and the first material to obtain a second material; heating the second material, adding polydimethylsiloxane, methylphenyldiethoxysilane, zinc stearate, oxidized polyethylene wax, triallyl isocyanurate and a heat stabilizer, and continuously performing stirring to obtain a third material; and heating the third material, adding a photoinitiator, sepiolite powder, aluminum borate whiskers and nano-silica, continuously performing stirring, cooling the obtained mixture to room temperature in a stirring state, and performing blow molding to obtain the high-sealing film for the paper-plastic composite bag. The preparation method is simple, and theobtained film has the advantages of uniform stress, high elongation at break, excellent sealing effect and complete degradation under natural conditions.

Owner:ANHUI SHUNKE PACKAGING PROD CO LTD

Environment-friendly automobile shock-absorbing rubber component

InactiveCN107163321AHigh degree of bindingIncrease elasticityWhey protein powderPoly-beta-hydroxybutyric acid

The invention discloses an environment-friendly automobile shock-absorbing rubber component which is prepared from the following raw materials in parts by weight: 100-110 parts of a matrix, 40-60 parts of a fiber complex, 2-7 parts of organobentonite, 40-60 parts of talcum powder, 3-12 parts of nano titanium dioxide, 3-6 parts of a vulcanization system, 1-2 parts of tricresyl phosphate, 1-2 parts of hydroxyl silicone oil, 1-2 parts of epoxidized soybean oil and 1-3 parts of an antioxidant. The fiber complex is prepared through the following processes of mixing whey protein powder and water, adjusting the pH value of the system to be 7.1-7.4; adding transglutaminase for enzymolysis and inactivation, adjusting the pH of the system to be neutral; adding a silane coupling agent, jute fiber and silk fiber for mixing evenly; and adding hydroxybutyric acid valeric acid copolyester and poly-beta-hydroxybutyric acid for mixing evenly, raising the temperature, further mixing, filtering, washing, drying and crushing to obtain the fiber complex.

Owner:HEFEI LYUJIE ENVIRONMENTAL PROTECTION TECH

Degradable environmental protection plastic

InactiveCN106046728AHigh tensile strengthHigh elongation at breakLow-density polyethyleneLinear low-density polyethylene

The invention discloses a degradable environmental protection plastic, which comprises the following raw materials: a polylactic acid resin, modified poly-beta-hydroxybutyric acid PHB, diisononyl phthalate DINP, pentaerythritol rosin ester, pea protein powder, oxidized lotus root starch, basic white clay, calcium carbonate, musa textilis nee fibers, linear low density polyethylene grafted maleic anhydride, gamma-glycidyl ether oxypropyl trimethoxysilane, a methyl methacrylate-butadiene-styrene copolymer, aluminum potassium sulfate, citrate, an ethylene-vinyl acetate copolymer, N,N'-ethylenebisoleamide, diphenyl methane diisocyanate, an antifungal antimicrobial agent, a degradation agent, an antioxidant and a stabilizer. The degradable environmental protection plastic of the present invention has advantages of good tensile strength, good elongation at break, good impact resistance, low water absorption, and good light transmittance, can be completely degraded into carbon dioxide and water after 133-137 days, and can not cause harm on the environment.

Owner:GUANGXI NANNING ZHICUI SCI TECH CONSULTATION CO LTD

An environmentally friendly plastic material with slow decomposition rate and low water absorption

The invention discloses an environment-friendly plastic material with a low decomposition rate and a low water absorptivity. The environment-friendly plastic material is prepared from the raw materials in parts by weight: 20-25 parts of PCL (polycaprolactone), 65-70 parts of modified PHB (poly-beta hydroxybutyric acid), 13-18 parts of a peanut protein powder, 1.5-1.8 parts of jute fiber, 3-4 parts of wood fiber, 1.1-1.3 parts of a silane coupling agent A-151, 2-3 parts of sodium lactate, 1.1-1.6 parts of sodium diacetate, 2-2.2 parts of dioctyl phthalate DOP, 5-7 parts of epoxy tall butyl oleate, 2-4 parts of oxidized starch, 20-23 parts of nano white carbon black, 6-8 parts of light calcium carbonate, 3-5 parts of sea-foam stone powder, 5-9 parts of kaolin and 1-1.4 part of antioxidant. The environment-friendly plastic material can be degraded by natural microbes and has the advantages of low decomposition rate, oxidation resistance, good shock resistance and low water absorptivity.

Owner:中山佳晨实业有限公司

Ratproof and anti-termite PA-ABS environment-friendly plastic

The invention discloses ratproof and anti-termite PA-ABS environment-friendly plastic. The ratproof and anti-termite PA-ABS environment-friendly plastic is prepared from the following raw materials in parts by weight: 70-80 parts of polyamide, 30-40 parts of acrylonitrile-butadiene-styrene, 18-22 parts of polycaprolactone, 25-30 parts of modified poly-beta-hydroxybutyric acid, 13-18 parts of crosslinked starch, 1.5-1.8 parts of glass fiber, 3-4 parts of lignin, 1.1-1.3 parts of a silane coupling agent, 2-3 parts of methyl parahydroxybenzoate, 1.1-1.6 parts of potassium sorbate, 2-2.2 parts of diisononyl phthalate, 5-7 parts of epoxidized soybean oil butyl ester, 6-8 parts of precipitated barium sulphate, 3-5 parts of zeolite powder, 23-26 parts of nano white carbon black and 1-1.4 parts of antioxidant. The ratproof and anti-termite PA-ABS environment-friendly plastic is good in mechanical properties, excellent in tensile strength and elongation at break and high in impact strength, has excellent heat ageing property, is suitable for use in an extremely high temperature environment and can not produce irreversible harm to the environment.

Owner:ZIBO KUAKE MEDICINE TECH

Apparatus and method for biological sewage treatment with effects of nitrogen and phosphorus synchronous removal and sludge reduction

InactiveCN106116059AReduce yieldRelieve pressureWater treatment parameter controlSpecific water treatment objectivesSludgeWater quality

Disclosed are an apparatus and a method for biological sewage treatment with effects of nitrogen and phosphorus synchronous removal and sludge reduction. The apparatus comprises a water inlet pipe 1, an anaerobic tank 2, a median settling tank 3, an intermediate water tank 4, a biological aerated filter (BAF) 5, an anoxic tank 6, a rear aeration tank 7, a secondary settling tank 8 and a water outlet pipe 9 connected in sequence. The method for biological sewage treatment includes mixing raw water and P-enriched returned sludge in the anaerobic tank, utilizing denitrifying phosphorus removing bacteria (DPBs) to absorb volatile organic acid (VFA) and store the same in the form of poly Beta-hydroxybutyric acid (PHB) while releasing a great quantity of phosphorus; carrying out removal of residual COD and nitrification of nitrogen by the BAF, delivering nitrification liquor of the BAF and sludge of the median settling tank into the anoxic tank together, and utilizing the DPBs in the anoxic tank to carry out denitrifying phosphorus-uptake by taking in-vivo PHB as energy source and carbon source and taking NO3<-> as an electron acceptor; removing residue phosphorus and blowing off nitrogen gas to avoid sludge floating in the rear aeration tank, delivering the mixture liquid into the secondary settling tank, discharging supernate, returning a part of sludge containing a great quantity of DPBs and discharging residual sludge. By the method, the problem of conflict between nitrogen removal and phosphorus removal is solved, quality stability of outlet water is guaranteed, and yield of sludge is low.

Owner:天津美能科技有限公司

A protein plastic material

The invention discloses a protein plastic material comprising the following raw materials in parts by weight: 45-50 parts of PBS (poly butylenes succinate), 30-35 parts of poly-beta-hydroxybutyric acid (PHB), 20-25 parts of peanut protein powder, 2.5-3 parts of potassium titanate fiber, 5-7 parts of silk fiber, 1.2-1.7 parts of a silane coupling agent KH570, 2-3 parts of sodium sorbate, 1.1-1.6 parts of ethyl p-hydroxybenzoate, 1.7-1.9 parts of diisooctyl phthalate (DIOP), 3-6 parts of epoxidized soybean oil, 3-5 parts of starch acetate, 15-18 parts of talcum powder, 7-11 parts of wollastonite powder, 5-9 parts of calcite powder and 1-1.4 parts of tert-butylhydroquinone (TBHQ). The protein plastic material disclosed by the invention can be decomposed by microorganisms, and is strong in ductility and good in impact resistance and oxidation resistance, the generation of white pollution can be avoided and the consumption of agricultural product resources can also be reduced.

Owner:威海正森新材料科技有限公司

Novel plastic

InactiveCN106349662AHigh tensile strengthHigh elongation at breakFiberLinear low-density polyethylene

The invention discloses a novel plastic which is prepared from a polylactic acid resin, modified poly-beta-hydroxybutyric acid (PHB), diisononyl phthalate (DINP), octadecyl acrylate, soybean albumen powder, oxidized corn starch, alkaline argil, calcium carbonate, bamboo fibers, linear low density polyethylene graft maleic anhydride, gamma-glycidoxypropyltrimethoxysilane, a methyl methacrylate-butadiene styrene-copolymer, aluminum potassium sulfate, citrate, an ethylene-vinyl acetate copolymer, ethylene bis oleamide, diphenylmethane diisocyanate, a mildewproof antimicrobial agent, a degradation agent, an antioxidant, a stabilizer, a flame retardant, a smoke inhibitor, a tackifier, a softener and an ultraviolet absorbent. The novel plastic has the advantages of favorable tensile strength, favorable elongation at break, favorable impact resistance, lower water absorptivity and favorable light transmittance. The novel plastic can be completely degraded into carbon dioxide and water after 138-142 days, and thus, can not do harm to the environment.

Owner:冯可发

Preparation method of water-resisting waterborne acrylic coating

The invention discloses a preparation method of water-resisting waterborne acrylic coating. The preparation method comprises the following steps: uniformly mixing poly-beta-hydroxybutyric acid and glycerol; adding chitosan and stirring; adding hydroxyapatite and continually stirring; cooling and filtering; adding absolute ethyl alcohol and uniformly stirring; raising the temperature, adding polyethylene glycol and stirring; evaporating and recycling the absolute ethyl alcohol; washing a microsphere product with water and drying to obtain a first material; uniformly mixing de-ionized water, a thickener, a de-foaming agent, a dispersant and a wetting agent; then adding fused white carbon black, wollastonite powder and the first material and stirring to obtain a second material; adding nano acrylic emulsion, epoxy resin, a flatting agent and sodium carboxymethyl cellulose into the second material and uniformly stirring; then adding a film-forming auxiliary agent and uniformly stirring; adjusting a system to be neutral to obtain the water-resisting waterborne acrylic coating. The preparation method disclosed by the invention is simple; the obtained water-resisting waterborne acrylic coating is reasonable in composition, low in cost and full in paint film, has good decoration function and environment protection function and meets environment protection requirements.

Owner:合肥林邦门业有限公司

A kind of environment-friendly poly-β-hydroxybutyric acid plastic material

ActiveCN104231581BReasonable control of the amount addedImprove mechanical propertiesEthyl hydroxybenzoateSilanes

The invention discloses an environment-friendly poly-beta-hydroxybutyric acid plastic material. The environment-friendly poly-beta-hydroxybutyric acid plastic material is composed of raw materials including, by weight part, 15-20 parts of corn starch, 8-12 parts of 5-7% polyvinyl alcohol solution, 0.5-0.8 part of 25-35% crosslinking agent and glycol water solution, 8-12 parts of cashew phenolic resin, 25-30 parts of poly-beta-hydroxybutyric acid, 5-8 parts of potassium titanate fiber, 2-3 parts of gamma-(methylacryloyl oxygen) methyl propyl trimethoxy silane, 2-2.5 parts of ethyl p-hydroxybenzoate, 1.5-2 parts of di-2-ethylhexyl phthalate, 0.5-0.8 part of urea, 5-8 parts of epoxidized soybean oil, 4-8 parts of silk fiber, 5-8 parts of starch acetate, 20-25 parts of talcum powder, 15-20 parts of calcite powder, 2-2.5 parts of tert-butylhydroquinone, 20-25 parts of glycerol and 15-18 parts of distilled water. The environment-friendly poly-beta-hydroxybutyric acid plastic material is environmentally friendly, high in biodegradation performance and waterproof performance and excellent in ageing-resistant performance and mechanical performance.

Owner:GUANGDONG KAIYU SCI & EDUCATION CULTURE CO LTD

Environment-friendly plastic

InactiveCN106280331AHigh tensile strengthHigh elongation at breakFiberLinear low-density polyethylene

The invention discloses environment-friendly plastic. The plastic is prepared from the following raw materials: polylactic resin, modified poly-beta-hydroxybutyric acid PHB, diisononyl phthalate DINP, epoxy tall oil butyl acetate, peanut protein flour, oxidized corn starch, alkaline clay, calcium carbonate, jute fibers, linear low-density polyethylene grafted maleic anhydride, gamma- glycidoxy propyl trimethoxy silane, methyl methacrylate-butadiene-styrene copolymer, aluminum potassium sulfate, citrate, ethylene-vinyl acetate copolymer, ethylene bis-oleamide, diphenyl-methane-diisocyanate, an antimycotic antibacterial agent, a degradation agent, antioxidant and a stabilizing agent. The environment-friendly plastic has good tensile strength and elongation at break, has good impact resistance, relatively low moisture absorption and good light transmittance, and can be completely degraded into carbon dioxide and water in 132-135 days, and has no pollution to the environment.

Owner:GUANGXI NANNING ZHICUI SCI TECH CONSULTATION CO LTD

Novel degradable plastic

InactiveCN106317813AHigh tensile strengthHigh elongation at breakFiberLinear low-density polyethylene

The invention discloses novel degradable plastic which comprises polylactic resin, modified poly-beta-hydroxybutyric acid PHB, diisononyl phthalate DINP, epoxy butyl stearate, black bean protein powder, oxidized sweet potato starch, alkaline carclazyte, calcium carbonate, jute fiber, linear low density polyethylene grafted maleic anhydride, gamma-glycidyl ether propoxy trimethoxy silane, methyl methacrylate-butadiene-styrene copolymer, aluminum potassium sulfate, citrate, vinyl-ethylene copolymer, ethylene bis oleamide, diphenylmethane diisocyanate, mildewproof antibacteiral agent, degrading agent, antioxidant and stabilizer. The novel degradable plastic has high tensile strength and elongation at break, is good in impact-resistant performance, low in hydroscopicity and high in light transmittance, can be completely degraded into carbon dioxide and water after 133-136 days and is free of causing damage to environment.

Owner:GUANGXI NANNING ZHICUI SCI TECH CONSULTATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com