An environmentally friendly plastic material with slow decomposition rate and low water absorption

A decomposition rate, environmentally friendly plastic technology, applied in the field of plastic materials, can solve the problems of fast decomposition rate, oxidation resistance, weak impact resistance, strong water absorption, etc., to improve tensile strength and elongation at break, and improve wear resistance Effect of improving tear resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

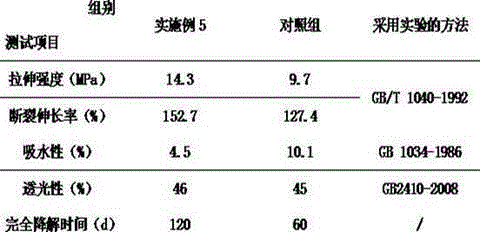

Examples

Embodiment 1

[0014] The present invention proposes an environmentally friendly plastic material with slow decomposition rate and low water absorption. The raw materials include 20 parts of polycaprolactone PCL, 70 parts of modified poly-β-hydroxybutyric acid PHB, 13 parts of peanut protein powder, jute 1.8 parts of fiber, 3 parts of wood fiber, 1.3 parts of silane coupling agent A-151, 2 parts of sodium lactate, 1.6 parts of sodium diacetate, 2 parts of dioctyl phthalate DOP, 7 parts of epoxy tall oleate, oxidized 2 parts of starch, 23 parts of nano-silica, 6 parts of light calcium carbonate, 5 parts of sepiolite powder, 9 parts of kaolin, 1 part of antioxidant, wherein the modified poly-β-hydroxybutyric acid PHB is poly-β-hydroxy It is obtained by blending and modifying butyric acid PHB and high cis-butadiene rubber;

[0015] During the preparation process, the silane coupling agent A-151 was added to jute fiber and wood fiber and stirred at a stirring speed of 30rpm for 6min, then peanut...

Embodiment 2

[0017] The present invention proposes an environmentally friendly plastic material with slow decomposition rate and low water absorption. The raw materials include 24 parts of polycaprolactone PCL, 66 parts of modified poly-β-hydroxybutyric acid PHB, 16 parts of peanut protein powder, jute 1.6 parts of fiber, 3.4 parts of wood fiber, 1.15 parts of silane coupling agent A-1515, 2.7 parts of sodium lactate, 1.3 parts of sodium diacetate, 2.16 parts of dioctyl phthalate DOP, 5.4 parts of epoxy tall oleate , 3.6 parts of oxidized starch, 21 parts of nano-silica, 7.3 parts of light calcium carbonate, 3.1 parts of sepiolite powder, 5 parts of kaolin, 1.3 parts of antioxidant, wherein the modified poly-β-hydroxybutyric acid PHB is poly-β - Hydroxybutyric acid PHB and high cis-butadiene rubber are blended and modified at a weight ratio of 1:1.5;

[0018] During the preparation process, the silane coupling agent A-151 was added to jute fiber and wood fiber and stirred at a stirring spe...

Embodiment 3

[0020] The present invention proposes an environmentally friendly plastic material with slow decomposition rate and low water absorption. The raw materials include 25 parts of polycaprolactone PCL, 65 parts of modified poly-β-hydroxybutyric acid PHB, 18 parts of peanut protein powder, jute 1.5 parts of fiber, 4 parts of wood fiber, 1.1 parts of silane coupling agent A-151, 3 parts of sodium lactate, 1.1 parts of sodium diacetate, 2.2 parts of dioctyl phthalate DOP, 5 parts of epoxy tall oleate , 4 parts of oxidized starch, 20 parts of nano-silica, 8 parts of light calcium carbonate, 3 parts of sepiolite powder, 7 parts of kaolin, 1.4 parts of antioxidant, wherein the modified poly-β-hydroxybutyric acid PHB is poly-β - Hydroxybutyric acid PHB and high cis-butadiene rubber are blended and modified at a weight ratio of 2:1;

[0021]During the preparation process, the silane coupling agent A-151 was added to jute fiber and wood fiber and stirred at a stirring speed of 33rpm for 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com