Titanium alloy drinking water filter element

A titanium alloy and drinking water technology, applied in the field of water filter elements, can solve the problems of secondary pollution of water, poor bacterial filtration ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0044] Specific embodiment 1: a filter element for drinking water, the filter element includes a skeleton layer and a fiber layer, the skeleton layer is formed into a porous structure by a ceramic material, the fiber layer is a metal fiber, and the fiber layer A filter membrane is attached to each layer, and the filter membrane is formed by spinning poly-β-hydroxybutyric acid, and the thickness of the filter membrane is 20 μm. The poly-β-hydroxybutyric acid is modified by grafting β-hydroxyethyl methacrylate.

[0045] The preparation method of described poly-beta-hydroxybutyric acid is as follows:

[0046] Step 1: get the bacillus strain;

[0047] Step 2: Cultivate the bacillus species in a nitrogen-free medium for 60 hours;

[0048] Step 3: Dilute and inoculate the above culture solution on a plate by 20-fold dilution method, culture at 25°C-29°C for 3 hours, and pick a single colony for live;

[0049] Step 4: Inoculate the above-mentioned bacterial liquid into the basal m...

specific Embodiment 2

[0054] Specific embodiment 2: a filter element for drinking water, the filter element includes a skeleton layer and a fiber layer, the skeleton layer is formed into a porous structure by a ceramic material, the fiber layer is a metal fiber, and the fiber layer A filter membrane is attached to each layer, and the filter membrane is formed by spinning poly-β-hydroxybutyric acid, and the thickness of the filter membrane is 20 μm. The poly-β-hydroxybutyric acid is modified by grafting β-hydroxyethyl methacrylate.

[0055] The preparation method of described poly-beta-hydroxybutyric acid is as follows:

[0056] Step 1: get the bacillus strain;

[0057] Step 2: Cultivate the bacillus species in a nitrogen-free medium for 60 hours;

[0058] Step 3: Dilute and inoculate the above culture solution on a plate by 20-fold dilution method, culture at 25°C-29°C for 3 hours, and pick a single colony for live;

[0059] Step 4: Inoculate the above-mentioned bacterial liquid into the basal m...

specific Embodiment 3

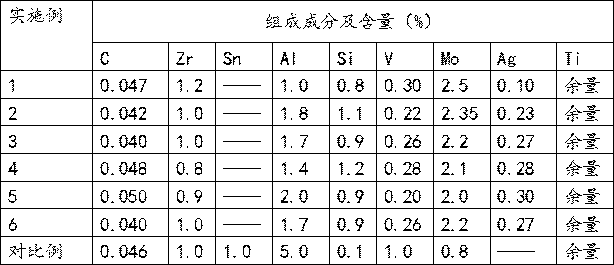

[0064] Specific embodiment 3: table 1 has listed the component content of some embodiment titanium alloys: (the surface of the sealing cover of following embodiment 1-5 all does not have silver infiltration alloy layer, the surface of the sealing cover of embodiment 6 has 30 μm silver alloy layer)

[0065]

[0066] Note: The composition of Example 6 does not include the silver-infiltrated alloy layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com