Degradable environmental-friendly plastic

A technology of environmentally friendly plastics and degradation agents, which is applied in plastic preparation technology and the field of environmental protection, can solve the problems of fast decomposition rate, oxidation resistance, weak impact resistance, strong water absorption, etc., and achieve slow decomposition speed, good impact resistance and water absorption. Sexually low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

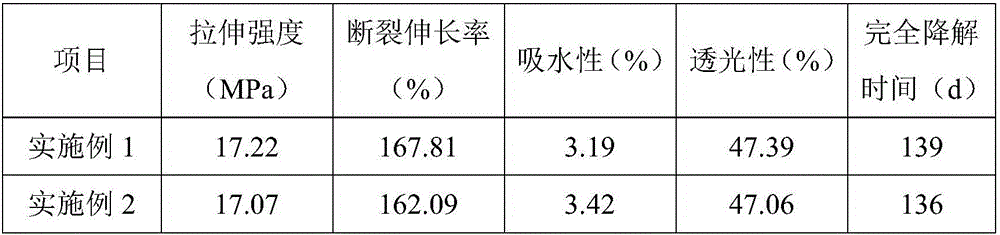

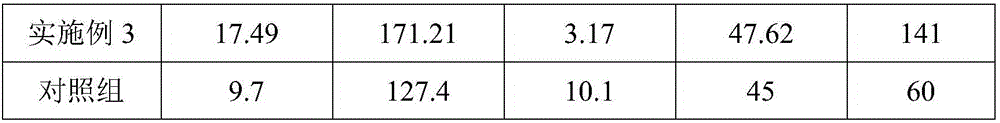

Examples

preparation example Construction

[0040] The preparation method of the degradable environment-friendly plastics comprises the following steps:

[0041] S1: Polylactic acid resin, modified poly-β-hydroxybutyrate PHB, diisononyl phthalate DINP, pentaerythritol rosin ester, linear low-density polyethylene grafted with maleic anhydride, γ-glycidyl ether oxypropylene Mix with trimethoxysilane, and stir for 10-15min at a temperature of 105-120°C and a rotation speed of 200-400r / min to obtain a mixture I;

[0042] S2: Under nitrogen protection, add alkaline clay, calcium carbonate, abaca fiber, methyl methacrylate-butadiene-styrene copolymer, aluminum potassium sulfate, citrate to the mixture I prepared in step 1 , ethylene-vinyl acetate copolymer, ethylene bisoleic acid amide, diphenylmethane diisocyanate, degradation agent, stirring at 120-180W ultrasonic power, 90-96°C temperature, and 200-300r / min rotation speed for 2 -2.5h, the mixture II was obtained;

Embodiment 1

[0047] A degradable environmentally friendly plastic, in parts by weight, comprising the following raw materials: 120 parts of polylactic acid resin, 80 parts of modified poly-β-hydroxybutyric acid PHB, 8 parts of diisononyl phthalate DINP, pentaerythritol rosin 20 parts of ester, 13 parts of mung bean protein powder, 10 parts of oxidized tapioca starch, 6 parts of alkaline clay, 5 parts of calcium carbonate, 12 parts of abaca fiber, 1.5 parts of linear low density polyethylene grafted maleic anhydride, γ-glycidol 1.5 parts of etheroxypropyltrimethoxysilane, 2.5 parts of methyl methacrylate-butadiene-styrene copolymer, 1.5 parts of potassium aluminum sulfate, 3.5 parts of citrate, 2.5 parts of ethylene-vinyl acetate copolymer, 2 parts of bisoleic acid amide, 1.5 parts of diphenylmethane diisocyanate, 2.1 parts of antifungal and antibacterial agent, 1.5 parts of degradation agent, 0.9 part of antioxidant, 0.8 part of stabilizer, 1 part of flame retardant, 0.8 part of smoke suppr...

Embodiment 2

[0065] A degradable environmentally friendly plastic, in parts by weight, comprising the following raw materials: 104 parts of polylactic acid resin, 78 parts of modified poly-β-hydroxybutyric acid PHB, 6 parts of diisononyl phthalate DINP, pentaerythritol 15 parts of rosin ester, 10 parts of mung bean protein powder, 7 parts of oxidized tapioca starch, 3 parts of alkaline clay, 3 parts of calcium carbonate, 8 parts of abaca fiber, 1 part of linear low density polyethylene grafted maleic anhydride, γ-shrinkage 1 part of glyceryl ether oxypropyltrimethoxysilane, 2 parts of methyl methacrylate-butadiene-styrene copolymer, 1 part of aluminum potassium sulfate, 3 parts of citrate, 2 parts of ethylene-vinyl acetate copolymer, 1 part of ethylene bisoleic acid amide, 1 part of diphenylmethane diisocyanate, 0.8 parts of antifungal and antibacterial agent, 1 part of degradation agent, 0.6 part of antioxidant, 0.5 part of stabilizer, 0.8 part of flame retardant, and 0.6 part of smoke sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com