Shell powder modified polylactic acid composite material, preparation method and applications thereof

A composite material and shell powder technology, which is applied in the field of environment-friendly shell powder modified polylactic acid composite materials and its preparation, can solve the problems of heat resistance, poor hydrophilicity, high price, etc., and achieve the effect of enhancing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

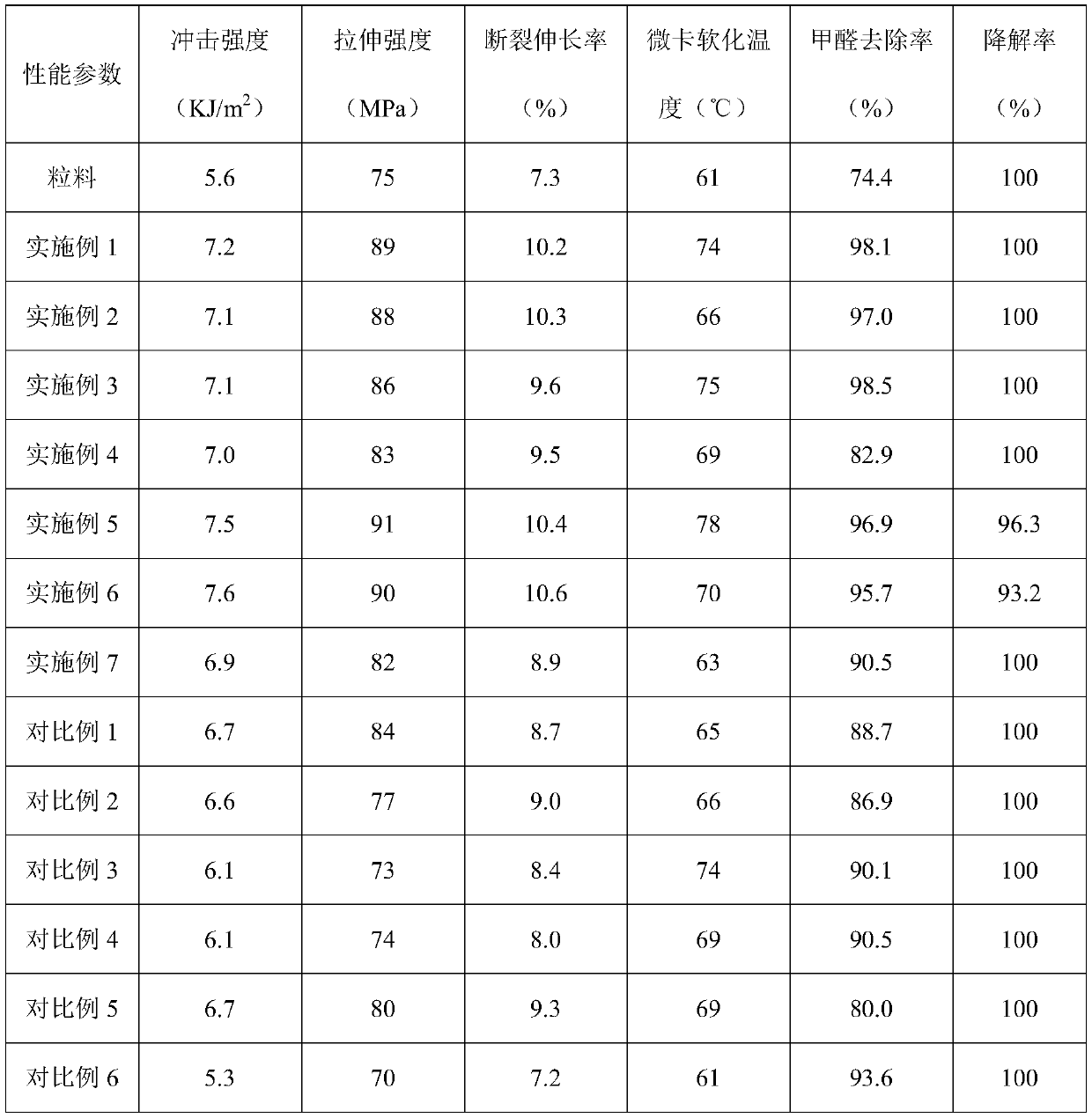

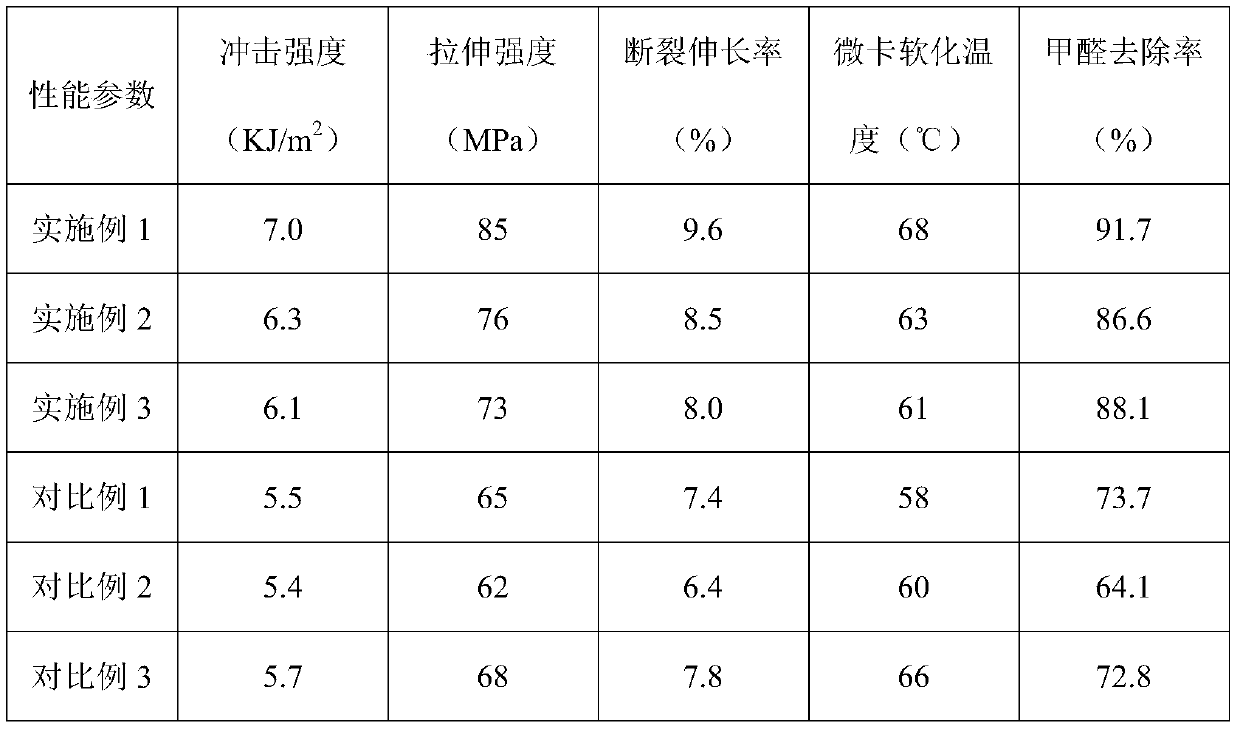

Examples

preparation example 1

[0053] Preparation Example 1 The preparation of shell powder with different particle sizes

[0054] Collect discarded shells, wash them with water, soak them in 8% sodium hydroxide solution for 18 hours, wash them with water at least 3 times after soaking, and then dry them in an oven at 100°C for 20 hours. Pulverize, pass through a 200-mesh sieve, and then use wet ball milling for 24 hours, filter with absolute ethanol, wash, and dry, and the particle size D50 value of the shell powder is 8 μm. Take out a part, and continue to use wet ball milling for 24 hours, filter with absolute ethanol, wash, and dry, and the D50 value of the particle size of the shell powder is 5 μm. Take out a part, and continue to use wet ball milling for 24 hours, filter with absolute ethanol, wash, and dry, and the D50 value of the particle size of the shell powder is 2 μm.

preparation example 2

[0056] S1: Dissolve 0.5 parts of surfactant sodium octadecyl sulfate in ethanol aqueous solution to make a solution with a mass concentration of 20%, add 20 parts of shell powder with a particle size D50 of 8 μm to the solution, soak for 20 minutes, put Bake in an oven at 100°C for 6 hours;

[0057] S2: Dissolve 1 part of silane coupling agent KH550, 2 parts of polyethylene glycol, 2 parts of carboxypolyethylene glycol acrylate, and 0.2 parts of dehydrating agent HOBT in aqueous ethanol to make a mixed solution, and prepare the Heat the shell powder to 70°C while stirring, spray the ethanol-water solution mixture on the shell powder, and continue stirring for 2 hours after spraying until the solvent evaporates;

[0058] S3: Dissolve 10 parts of chitosan-methacrylic acid graft copolymer and 100 parts of polylactic acid in dimethylformamide, heat to 45°C and stir to dissolve, add 0.5 parts of dimethyl sulfoxide, add step (2 ) prepared shell powder, mixed, heated and evaporated ...

preparation example 3

[0060] The other steps were the same as in Preparation Example 2, except that 2 parts of carboxypolyethylene glycol acrylate in step S2 were replaced with 2 parts of polyethylene glycol methacrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com