PC/ABS alloy with high and low temperature notch impact and its preparation method

A notch impact, high and low temperature technology, which is applied in the high and low temperature notch impact PC/ABS alloy and its preparation field, can solve the problems of appearance, physical property deterioration, high cost, and increased material cost, so as to improve fluidity, reduce defects, The effect of increasing the processing window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

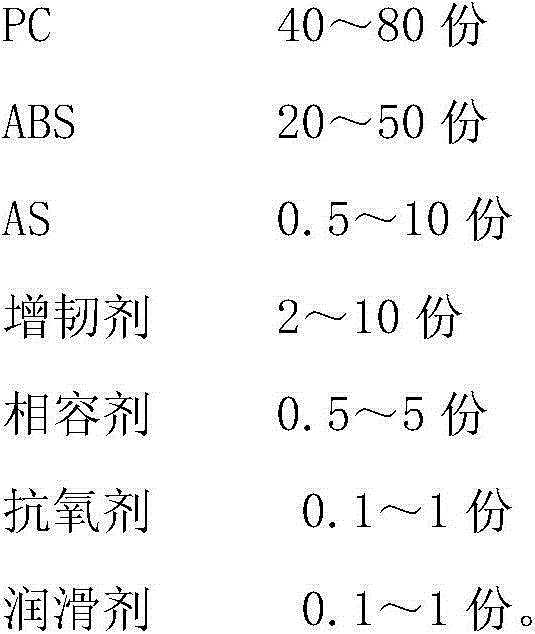

Method used

Image

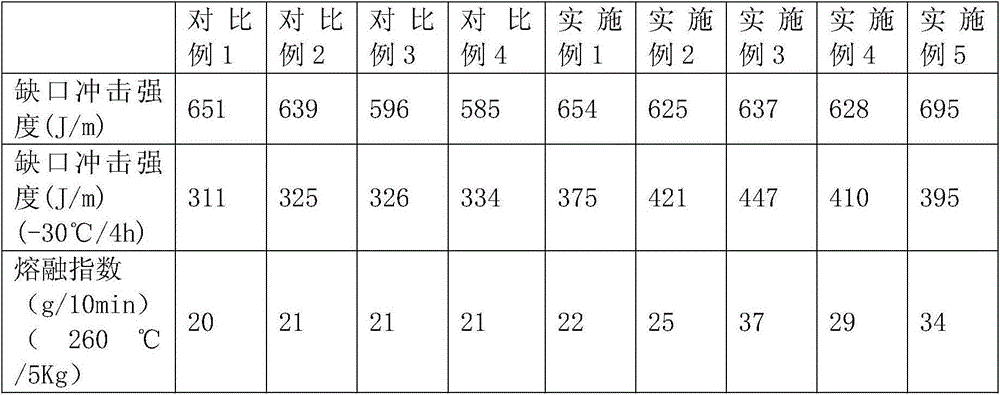

Examples

Embodiment 1

[0045] S01. Weigh 30Kg of PC-1100, 30Kg of PC-2200, 35Kg of ABS8391, MBS (methyl methacrylate-butadiene-styrene copolymer): 5Kg of EM505, compatibilizer XIRANSZ231102Kg, antioxidant 245 is 0.1Kg, antioxidant 168 is 0.1Kg, lubricant PETS (pentaerythritol stearate) is 0.5Kg, silicone powder is 0.5g;

[0046] S02, mixing the raw materials weighed in step S01 for 5 to 30 minutes to obtain a mixed material;

[0047] S03. Put the mixed material obtained in step S02 into a twin-screw extruder, control the screw speed to 500 rpm, melt extrude, and granulate to obtain the product.

Embodiment 2

[0049] S021. Weigh 30Kg of PC-1100, 30Kg of PC-2200, 35Kg of ABS8391, MBS (methyl methacrylate-butadiene-styrene copolymer): 5Kg of EXL-2620, 0.5Kg of AS, and Compatibility agent XIRANSZ231102Kg, antioxidant 245 is 0.1Kg, antioxidant 168 is 0.1Kg, lubricant PETS (pentaerythritol stearate) is 0.5Kg, silicone powder 0.5g

[0050] S022, mixing the raw materials weighed in step S021 for 5 to 30 minutes to obtain a mixed material;

[0051] S023. Put the mixed material obtained in step S022 into a twin-screw extruder, control the screw speed to 500 rpm, melt and extrude, and granulate to obtain the product.

Embodiment 3

[0053] S031. Weigh 30Kg of PC-1100, 30Kg of PC-2200, 25Kg of P / D150, MBS (methyl methacrylate-butadiene-styrene copolymer): 5Kg of EM500, 10Kg of AS, compatible Agent XIRANSZ231102Kg, antioxidant 245 is 0.1Kg, antioxidant 168 is 0.1Kg, lubricant PETS (pentaerythritol stearate) is 0.5Kg, silicone powder 0.5g;

[0054] S032, mixing the raw materials weighed in step S031 for 5 to 30 minutes to obtain a mixed material;

[0055] S033. Put the mixed material obtained in step S032 into a twin-screw extruder, control the screw speed to 500 rpm, melt and extrude, and granulate to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com