PC/PET halogen-free flame-retardant alloy containing recycled resin and preparation method thereof

A recycled resin and alloy technology, applied in the field of composition and its preparation, can solve the problems of PC/PET alloy compatibility, thermal stability and chemical resistance, poor chemical resistance, and brittle plastic parts Chemical and other issues, to achieve excellent physical and mechanical properties, good chemical resistance, increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

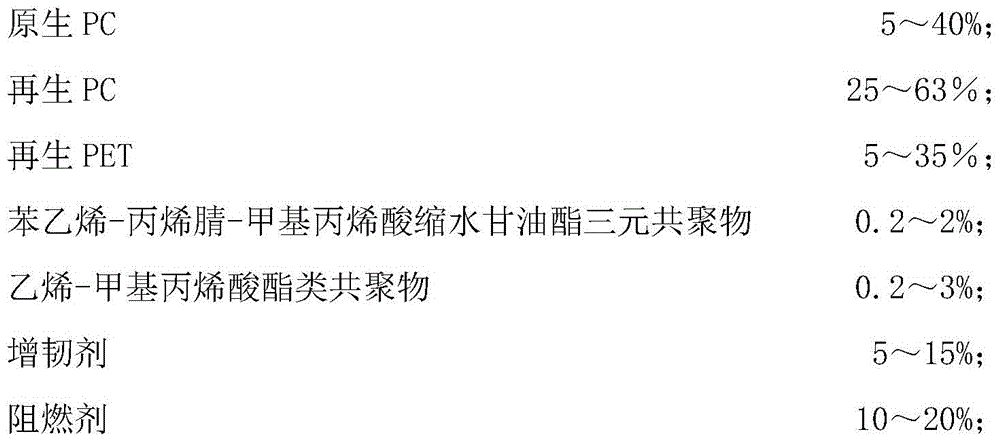

Method used

Image

Examples

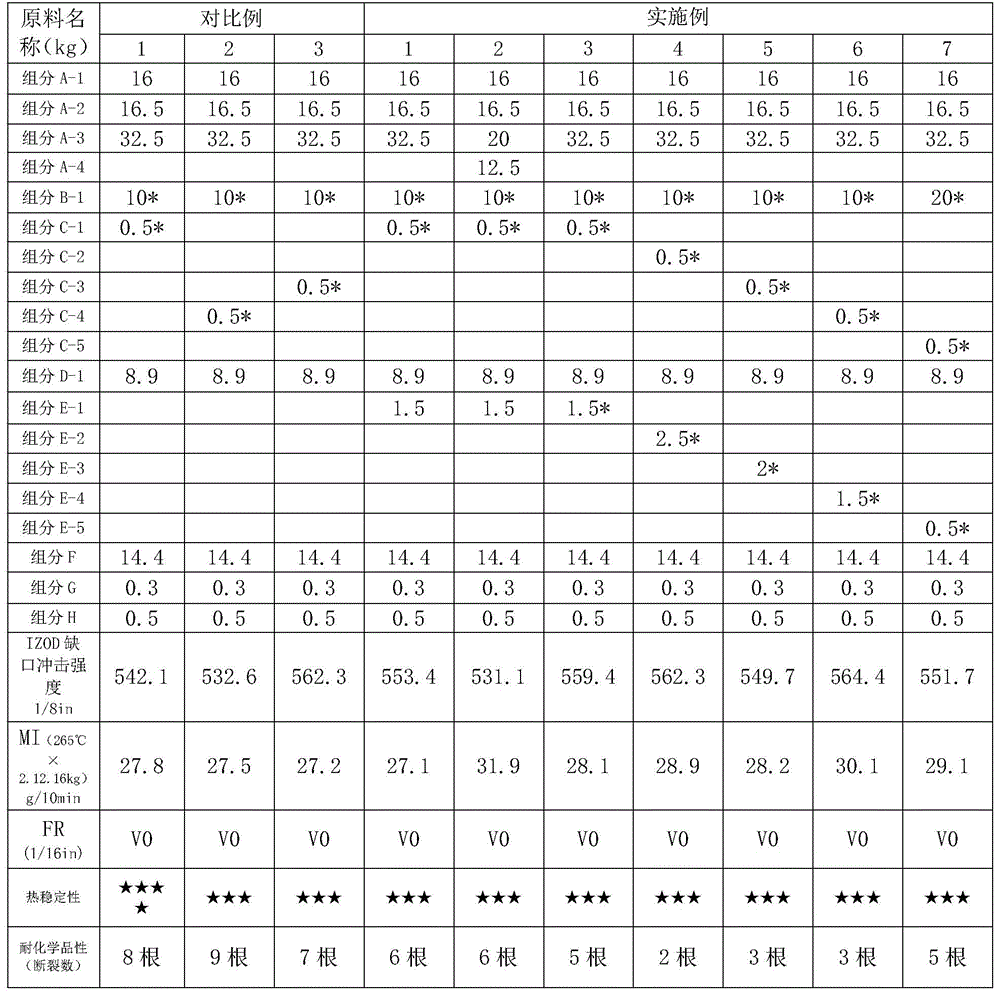

Embodiment 1~13 and comparative example 1~3

[0048] 1.1. Explanation of the meaning of the component code

[0049] Component A-1: PC, polycarbonate with a number average molecular weight of 25,000, produced by Hunan Petrochemical;

[0050] Component A-2: PC, polycarbonate with a number average molecular weight of 21,000, produced by Hunan Petrochemical;

[0051] Component A-3: Regenerated PC, commercially available, the number average molecular weight of polycarbonate is 24000;

[0052] Component A-4: Regenerated PC, commercially available, the number average molecular weight of polycarbonate is 15000;

[0053] Component B-1: recycled PET, commercially available, its source is PET beverage bottle flakes, with a viscosity of 0.8dl / g;

[0054] Component C-1: styrene-acrylonitrile copolymer-glycidyl methacrylate terpolymer (SAN-co-GMA), GMA content is 5%, acrylonitrile content is 28%;

[0055] Component C-2: styrene-acrylonitrile copolymer-glycidyl methacrylate terpolymer (SAN-co-GMA), GMA content is 2%, acrylonitril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com