Compound extrusion unit for producing tubeless bicycles and mouth device thereof

A composite extrusion and bicycle tire technology, which is applied in the field of bicycle tire manufacturing, can solve the problems affecting the appearance of the product, and achieve the effect of compact equipment structure, reduced volume and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

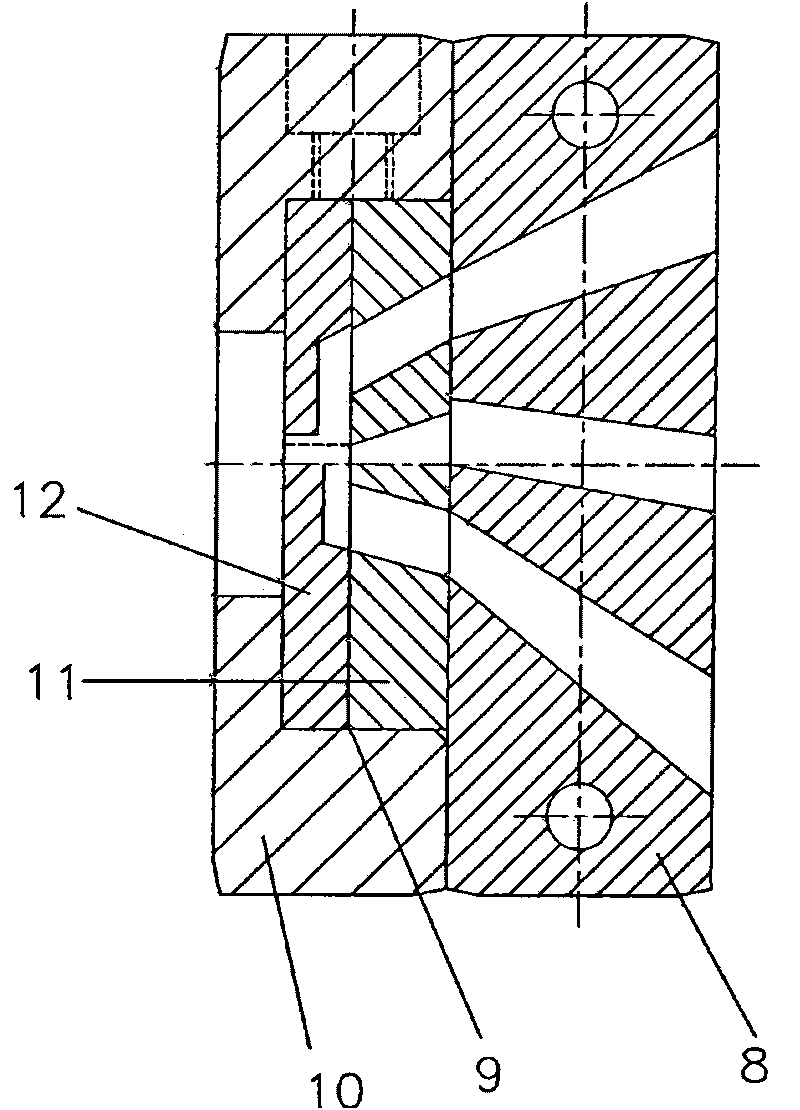

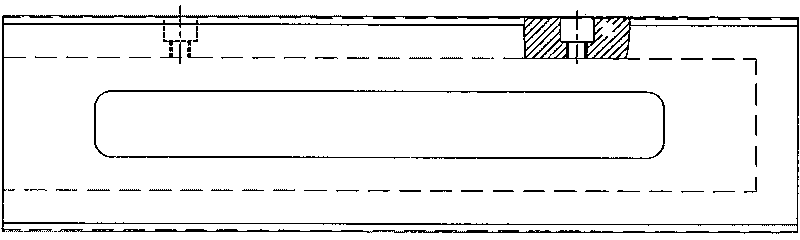

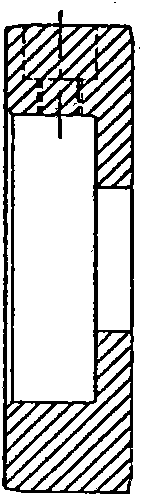

[0058] Present embodiment is a kind of mouth device that is used to produce the compound extruding unit of tubeless bicycle tire, as figure 1 As shown, according to the flow direction of the rubber material, it includes a pre-mouth plate 8, a mouth plate 9 and a mouth box 10 connected in sequence, wherein the mouth plate 9 is embedded in the mouth box 10 (the structure of the mouth box is as follows figure 2 with image 3 shown); wherein the pre-mouth type plate 8 is an integrated structure, and the mouth type plate 9 includes an upper mouth type plate 11 and a lower mouth type plate 12 that cooperate with each other.

[0059] The pre-mouth plate and the mouth plate are respectively provided with rubber material chambers corresponding to the flow channel ports on the head mold of the compound extrusion unit, including the upper rubber material chamber, the middle rubber material chamber and the lower rubber material chamber. The cavity is tapered. Such as Figure 4 with ...

Embodiment 2

[0065] Present embodiment is a kind of mouth device that is used to produce the compound extruding unit of tubeless bicycle tire, as figure 1 As shown, according to the flow direction of the rubber material, it includes a pre-mouth plate 8, a mouth plate 9 and a mouth box 10 connected in sequence, wherein the mouth plate 9 is embedded in the mouth box (the structure of the mouth box is as follows figure 2 with image 3 shown); wherein the pre-mouth type plate 8 is an integrated structure, and the mouth type plate 9 includes an upper mouth type plate 11 and a lower mouth type plate 12 that cooperate with each other.

[0066] The pre-mouth plate and the mouth plate are respectively provided with rubber material chambers corresponding to the flow channel ports on the head mold of the compound extrusion unit, including the upper rubber material chamber, the middle rubber material chamber and the lower rubber material chamber. The cavity is tapered. Such as Figure 10 As shown,...

Embodiment 3

[0072] Present embodiment is a kind of mouth device that is used to produce the compound extruding unit of tubeless bicycle tire, as figure 1 As shown, according to the flow direction of the rubber material, it includes a pre-mouth plate 8, a mouth plate 9 and a mouth box 10 connected in sequence, wherein the mouth plate 9 is embedded in the mouth box 10 (the structure of the mouth box is as follows figure 2 with image 3 shown); wherein the pre-mouth type plate 8 is an integrated structure, and the mouth type plate 9 includes an upper mouth type plate 11 and a lower mouth type plate 12 that cooperate with each other.

[0073] The pre-mouth plate and the mouth plate are respectively provided with rubber material chambers corresponding to the flow channel ports on the head mold of the compound extrusion unit, including the upper rubber material chamber, the middle rubber material chamber and the lower rubber material chamber. The cavity is tapered. Such as Figure 15 As sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com