Squeezing roller and rotary drum-type magnetic separator

A magnetic separation device, drum-type technology, applied in the direction of magnetic separation, solid separation, shafts and bearings, etc., can solve the problems of reduced extrusion efficiency, insufficient liquid extrusion, insufficient liquid removal, etc., to ensure durability Sexual, long-term stable liquid extrusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

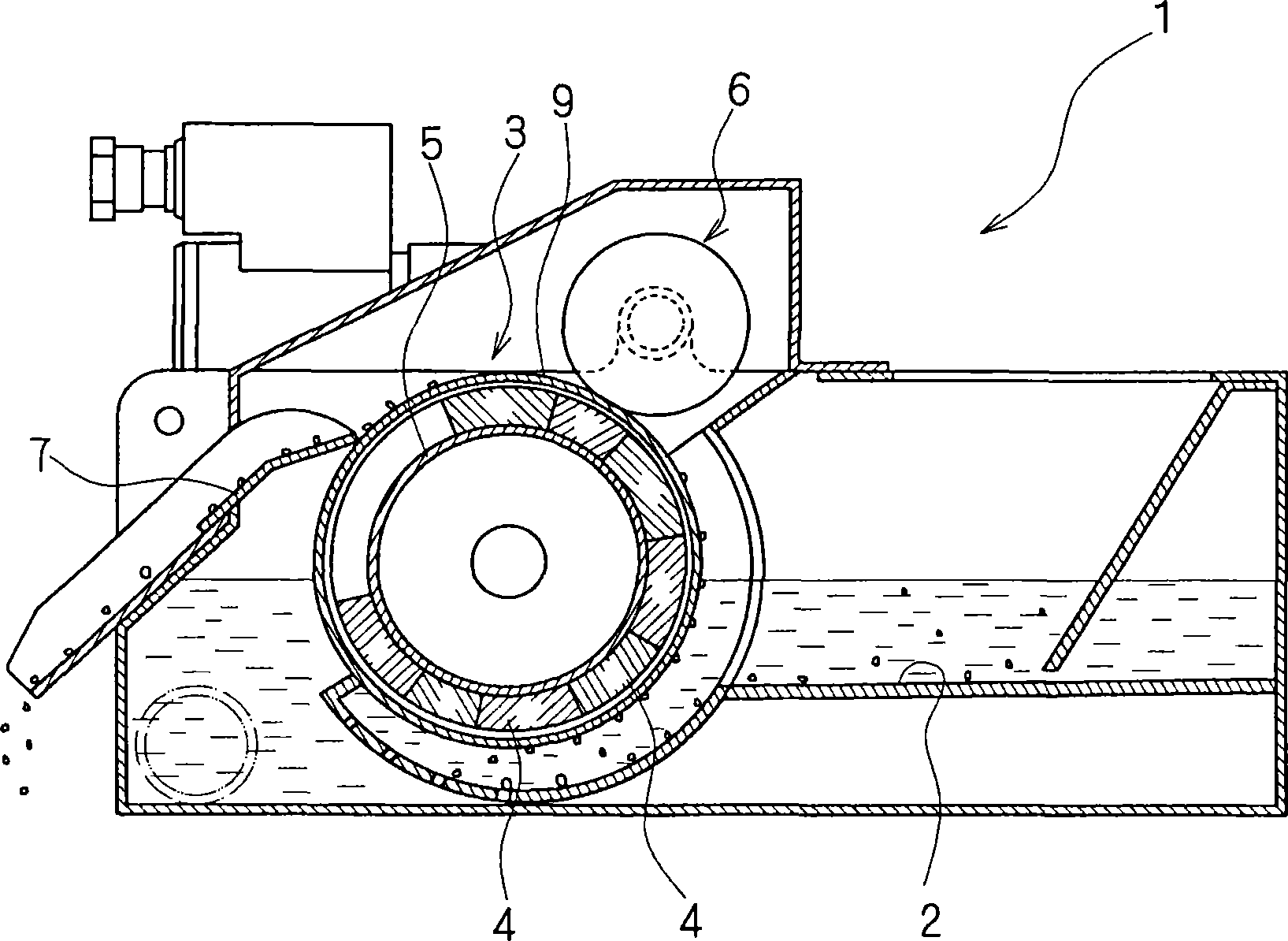

[0050] figure 1 It is a cross-sectional view showing the configuration of the rotating drum type magnetic separator according to Embodiment 1 of the present invention, taken along a plane perpendicular to the rotation axis of the rotating drum. Such as figure 1 As shown, in the rotating drum type magnetic separator of the first embodiment, a liquid storage part 2 for storing cooling liquid is provided in a box-shaped main body 1 . A rotary drum 3 is rotatably supported substantially horizontally in the vicinity of the central portion of the main body 1 so as to divide the liquid storage portion 2 into two. The rotary drum 3 is formed as a cylinder made of non-magnetic materials such as stainless steel, and an inner cylinder 5 is coaxially fixed inside the outer cylinder 9, and a plurality of magnets 4 are arranged in a predetermined arrangement on the outer peripheral surface of the inner cylinder 5. , 4, .... The polarities of the plurality of magnets 4 , 4 , .

[0051] e...

Embodiment approach 2

[0067] The cross-sectional view of the plane perpendicular to the direction of the rotation axis of the rotating drum showing the structure of the rotating drum type magnetic separator according to Embodiment 2 of the present invention is the same as Embodiment 1, and by giving figure 1 The same symbols are used to omit detailed description. The rotating drum type magnetic separator according to Embodiment 2 is different from Embodiment 1 in that it includes a suppressing member for suppressing the axial movement of the elastic body mounted on the surface of the pressure roller 6 .

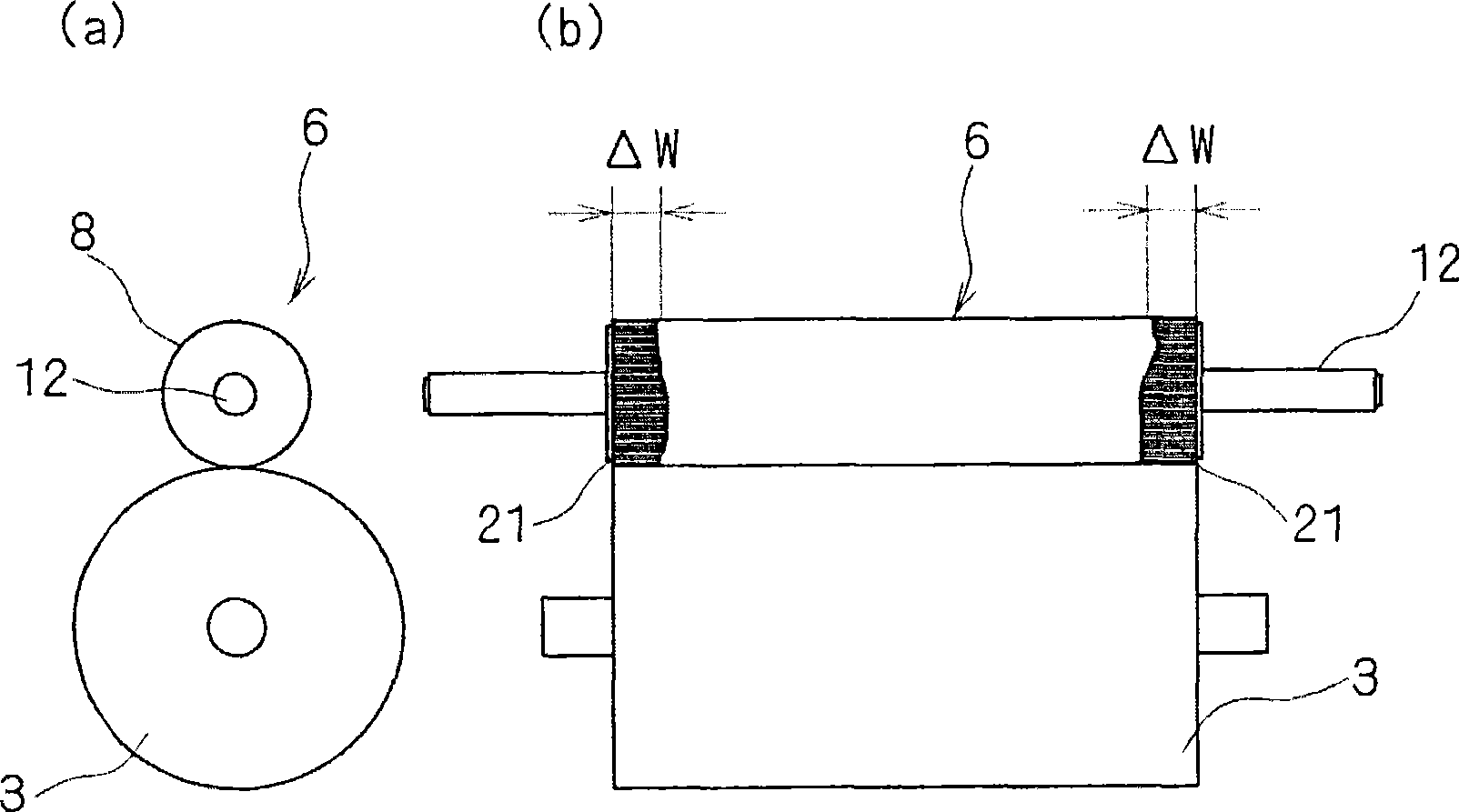

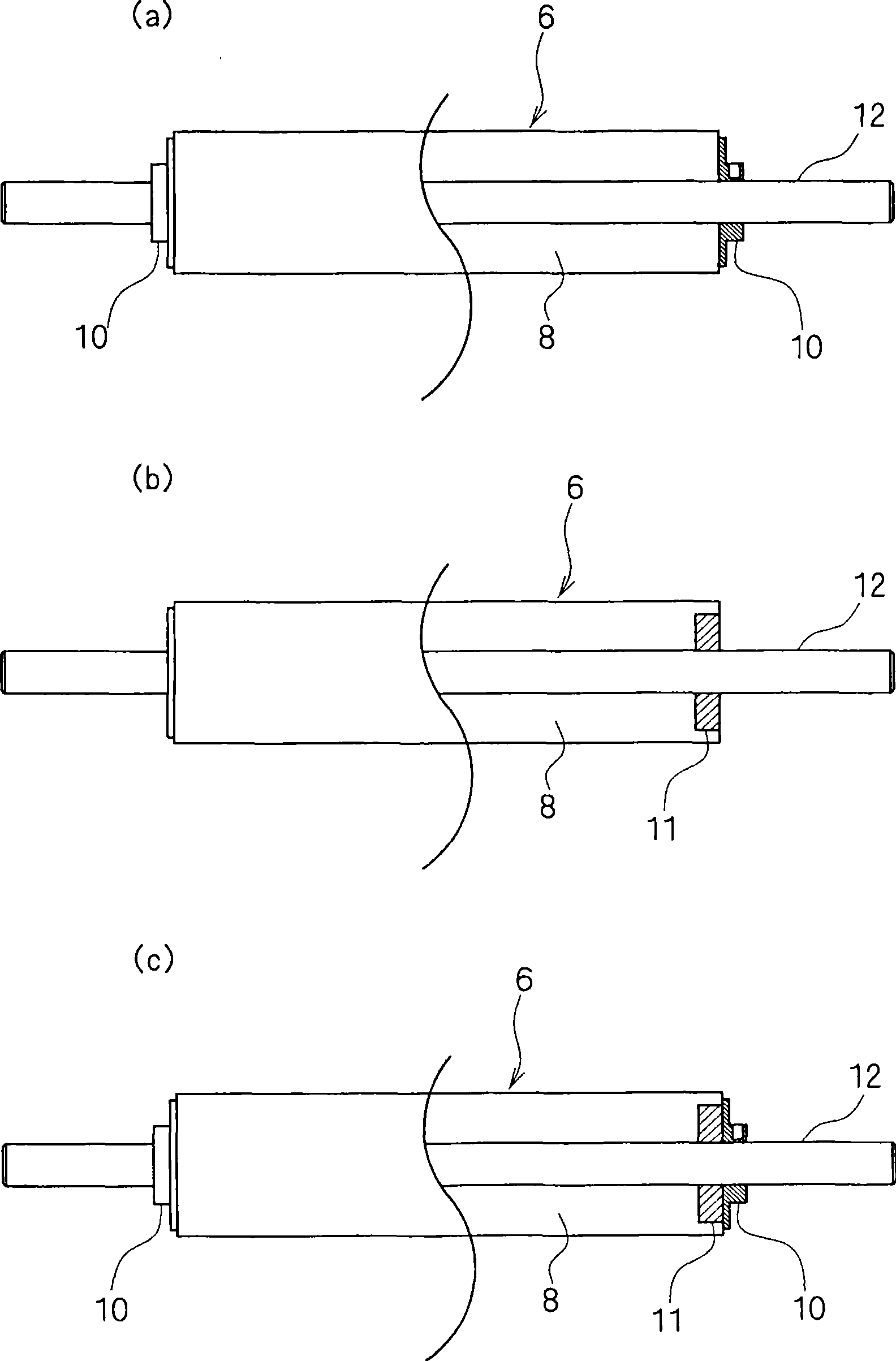

[0068] figure 2 It is a two-dimensional view showing the state of liquid leakage on the surface of the pressure roller 6 of the conventional rotary drum type magnetic separator. figure 2 (a) shows a side view of the pressing roller 6 and the rotating drum 3 of a conventional rotating drum type magnetic separator viewed from the direction of the rotating shaft, figure 2 (b) is a front view sho...

Embodiment approach 3

[0084] The cross-sectional view of the plane perpendicular to the direction of the rotation axis of the rotating drum showing the configuration of the rotating drum type magnetic separator according to Embodiment 3 of the present invention is the same as before, by giving the figure 1 The same symbols are used and detailed descriptions are omitted. The rotating drum type magnetic separator according to Embodiment 3 is characterized in that the polarities of the plurality of magnets 4 , 4 , . . . arranged on the inner cylinder 5 of the rotating drum 3 are arranged.

[0085] Fig. 4 is a sectional view and a front view showing the polarity arrangement of magnets 4, 4, ... of the rotating drum 3 of the rotating drum type magnetic separator according to Embodiment 3 of the present invention. Fig. 4 (a) shows the sectional view of the plane perpendicular to the rotation axis direction of the rotary drum 3 of the rotary drum type magnetic separator of Embodiment 3 of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com