Marine cable material which is resistant to high temperature and excellent in flame retardant performance and preparing method thereof

A flame retardant and marine cable technology, which is applied in the field of marine cable materials and its preparation, can solve the problems of unsatisfactory performance of marine cables, achieve good mechanical properties, excellent flame retardancy and high temperature resistance, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

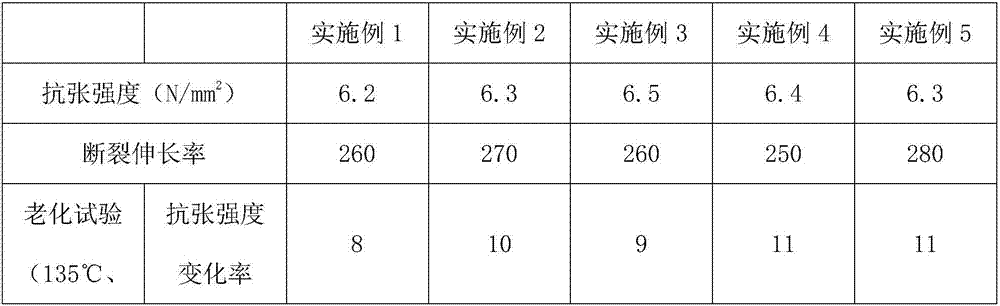

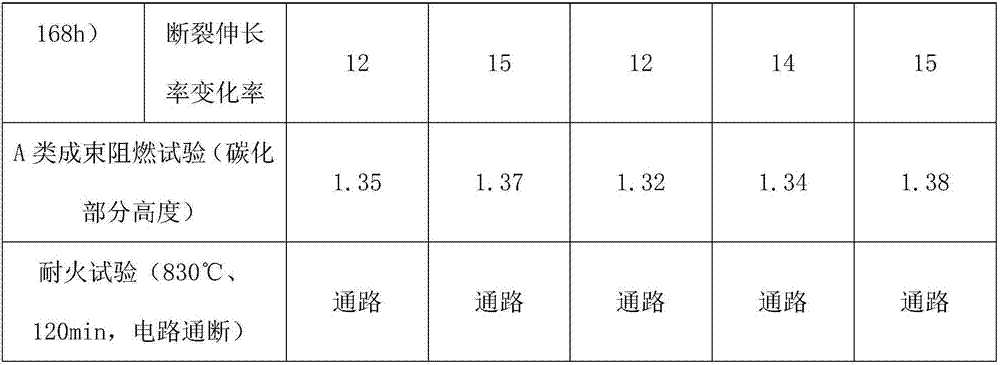

Examples

Embodiment 1

[0022] A marine cable material with high temperature resistance and excellent flame retardancy, which is made of the following raw materials in parts by weight: 100 parts of EPDM rubber, 35 parts of tetrapropylene fluorine rubber, 21 parts of polyisoprene rubber, peroxide 3 parts of benzoyl, 2 parts of dicumyl peroxide, 1 part of ethylene glycol dimethacrylate, 3 parts of calcium lignosulfonate, 0.3 parts of monoalkoxy unsaturated fatty acid titanate, wollastonite powder 6 parts, 4 parts of nano aluminum hydroxide, 2 parts of molybdenum trioxide, 1 part of tetrabromophthalic anhydride, 2 parts of white carbon black, 5 parts of melamine polyphosphate, 0.5 parts of antioxidant 1076, 0.8 parts of antioxidant RD share.

[0023] In this embodiment, the preparation method of the high temperature resistant and excellent flame retardant marine cable material, the steps are as follows:

[0024] 1) Weigh wollastonite powder, add it to citric acid solution with 60% of its weight, then a...

Embodiment 2

[0031] A marine cable material with high temperature resistance and excellent flame retardancy, which is made of the following raw materials in parts by weight: 103 parts of EPDM rubber, 36 parts of tetrapropylene fluorine rubber, 22 parts of polyisoprene rubber, peroxide 3.5 parts of benzoyl, 2.8 parts of dicumyl peroxide, 1.7 parts of ethylene glycol dimethacrylate, 4.5 parts of calcium lignosulfonate, 0.5 parts of monoalkoxy unsaturated fatty acid titanate, wollastonite powder 7 parts, 5 parts of nano aluminum hydroxide, 2.1 parts of molybdenum trioxide, 1.7 parts of tetrabromophthalic anhydride, 2.7 parts of white carbon black, 6.5 parts of melamine polyphosphate, 0.6 parts of antioxidant 1076, 1.1 parts of anti-aging agent RD share.

[0032] In this embodiment, the preparation method of the high temperature resistant and excellent flame retardant marine cable material, the steps are as follows:

[0033] 1) Weigh wollastonite powder, add it to citric acid solution with 61...

Embodiment 3

[0040]A marine cable material with high temperature resistance and excellent flame retardancy, which is made of the following raw materials in parts by weight: 105 parts of EPDM rubber, 37 parts of tetrapropylene fluorine rubber, 23 parts of polyisoprene rubber, peroxide 4 parts of benzoyl, 2.4 parts of dicumyl peroxide, 1.5 parts of ethylene glycol dimethacrylate, 4 parts of calcium lignosulfonate, 0.5 parts of monoalkoxy unsaturated fatty acid titanate, wollastonite powder 8 parts, 5.3 parts of nano-aluminum hydroxide, 2.4 parts of molybdenum trioxide, 1.5 parts of tetrabromophthalic anhydride, 2.6 parts of white carbon black, 5 parts of melamine polyphosphate, 0.8 parts of antioxidant 1076, 1 part of antioxidant RD share.

[0041] In this embodiment, the preparation method of the high temperature resistant and excellent flame retardant marine cable material, the steps are as follows:

[0042] 1) Weigh wollastonite powder, add it to the citric acid solution with 63% of its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com