Flame-retardant resin comprising phosphaphenanthrene compound, and synthesizing process and application thereof

A compound and phenanthrene technology, applied in the field of unsaturated polyester resin, can solve the problems of complex synthesis method, complicated product post-processing, low conversion rate of esterification reaction, etc., saving production time and production cost, and expanding the scope of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

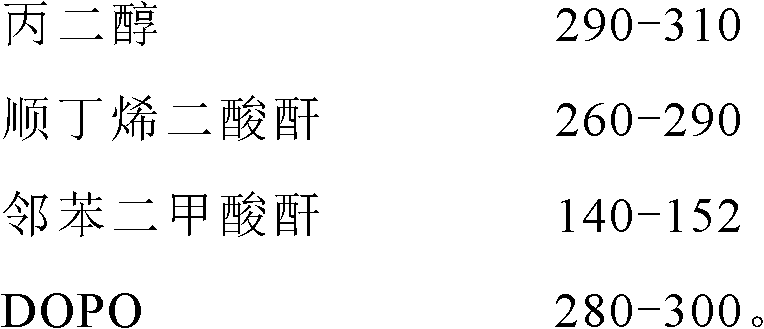

[0037] The unsaturated polyester resin containing phosphaphenanthrene compounds comprises the following components in parts by weight:

[0038]

[0039]

[0040] Synthesize as follows:

[0041] (1) Add propylene glycol and DOPO into a 1000ml four-necked bottle;

[0042] (2) heating up until DOPO is completely dissolved, adding 100 parts by weight of maleic anhydride in 3 times, and controlling the reaction temperature after adding to not exceed 130°C;

[0043] (3) After the addition is completed, the reaction temperature is controlled at 130°C-140°C for 2 hours;

[0044] (4) Add phthalic anhydride and remaining maleic anhydride, continue to heat up, and control the temperature of the distillation head at 98°C-100°C when the water comes out of the distillation head;

[0045] (5) Continue to heat up under the condition that the temperature of the distillation head does not exceed 101°C, but the temperature should not exceed 185°C;

[0046] (6) sampling test, after the a...

Embodiment 2

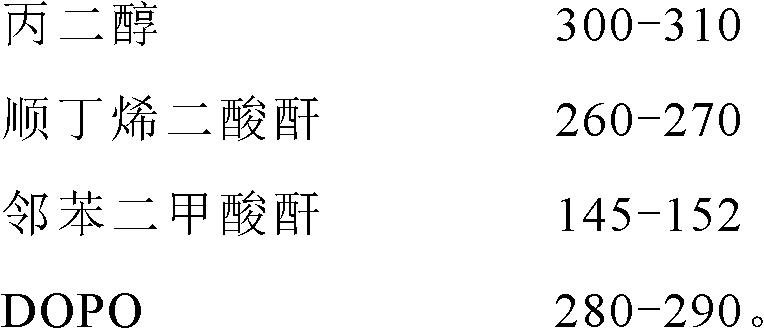

[0051] The unsaturated polyester resin containing phosphaphenanthrene compounds comprises the following components in parts by weight:

[0052]

[0053] Synthesize as follows:

[0054] (1) Add propylene glycol and DOPO into a 1000ml four-necked bottle;

[0055] (2) heating up until DOPO is completely dissolved, adding 100 parts by weight of maleic anhydride in 3 times, and controlling the reaction temperature after adding to not exceed 130°C;

[0056] (3) After the addition is completed, the reaction temperature is controlled at 130°C-140°C for 2 hours;

[0057] (4) Add phthalic anhydride and remaining maleic anhydride, continue to heat up, and control the temperature of the distillation head at 98°C-100°C when the water comes out of the distillation head;

[0058] (5) Continue to heat up under the condition that the temperature of the distillation head does not exceed 101°C, but the temperature should not exceed 185°C;

[0059] (6) sampling test, after the acid value of...

Embodiment 3

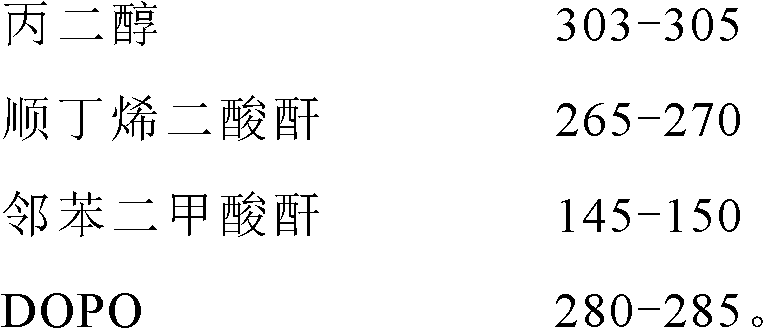

[0064] The unsaturated polyester resin containing phosphaphenanthrene compounds comprises the following components in parts by weight:

[0065]

[0066] Synthesize as follows:

[0067] (1) Add propylene glycol and DOPO into a 1000ml four-necked bottle;

[0068] (2) heating up until DOPO is completely dissolved, adding 100 parts by weight of maleic anhydride in 3 times, and controlling the reaction temperature after adding to not exceed 130°C;

[0069] (3) After the addition is completed, the reaction temperature is controlled at 130°C-140°C for 2 hours;

[0070] (4) Add phthalic anhydride and remaining maleic anhydride, continue to heat up, and control the temperature of the distillation head at 98°C-100°C when the water comes out of the distillation head;

[0071] (5) Continue to heat up under the condition that the temperature of the distillation head does not exceed 101°C, but the temperature should not exceed 185°C;

[0072] (6) sampling test, after the acid value of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com